Goods sorting system and sorting method

A sorting system and article technology, applied in the direction of sorting, etc., can solve the problems of lack of return (return to zero) detection mechanism of the pick, loose structure of the pick device, and inability to realize the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

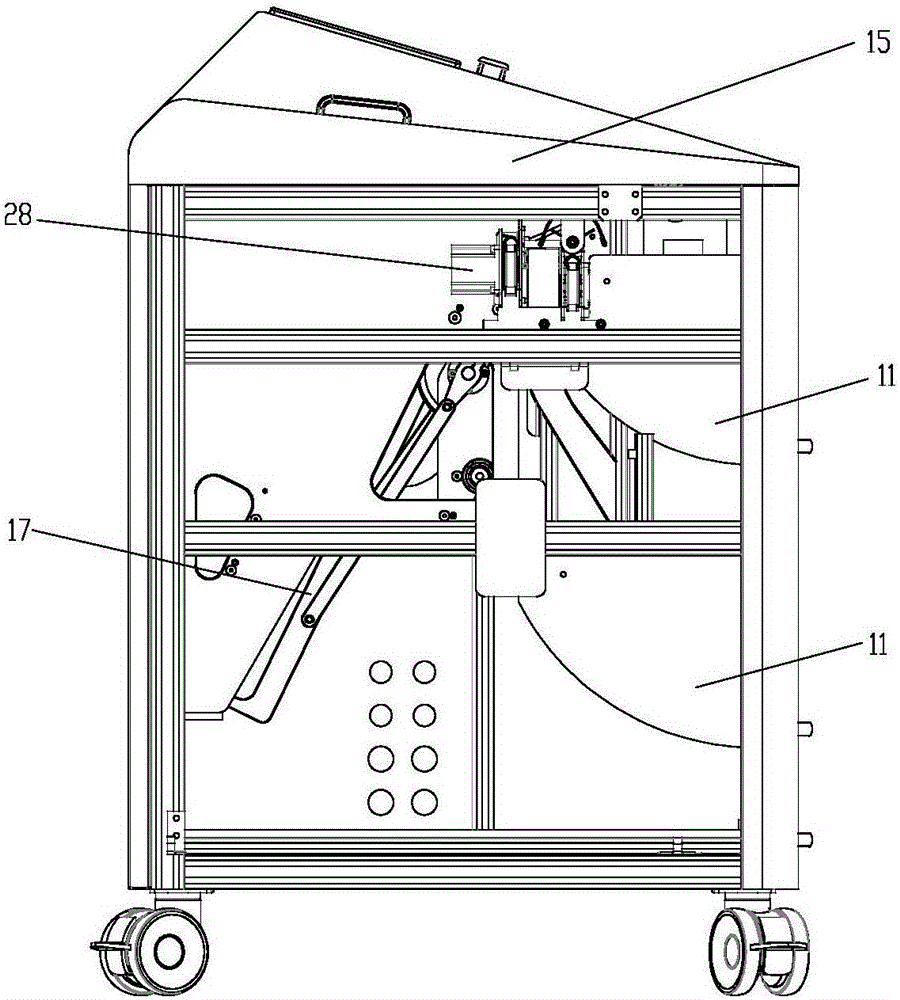

[0128] Figure 1-17 , an article sorting system, including a feeding device, a conveying device, a pushing device, a material pulling device and a sorting bin; the sorting bin includes a plurality of bin bodies;

[0129] The feeding device, the conveying device, the pushing device and the feeding device are connected in sequence;

[0130] The conveying device is a U-shaped rotary channel, and the U-shaped rotary channel includes a feeding line and a discharging line;

[0131] The feeding device is used to send the items to the feeding line;

[0132] The pushing device connects the feeding line and the discharging line; it is used to push the detected items on the feeding line to the discharging line;

[0133] The shifting device is used to shift each item on the unloading line into one of the bins;

[0134] The sorting bin is located under the feeding device;

[0135] The article sorting system also includes a controller; the feeding device, the pushing device and the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com