Grease composition and grease-filled wheel bearing

A grease composition and a technology for wheel bearings, which are applied in the field of wheel bearings, can solve the problems of insufficient fretting wear and wear suppression, and achieve the effects of low torque, long lubrication life, and fretting wear and wear suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] Preparation of Test Grease

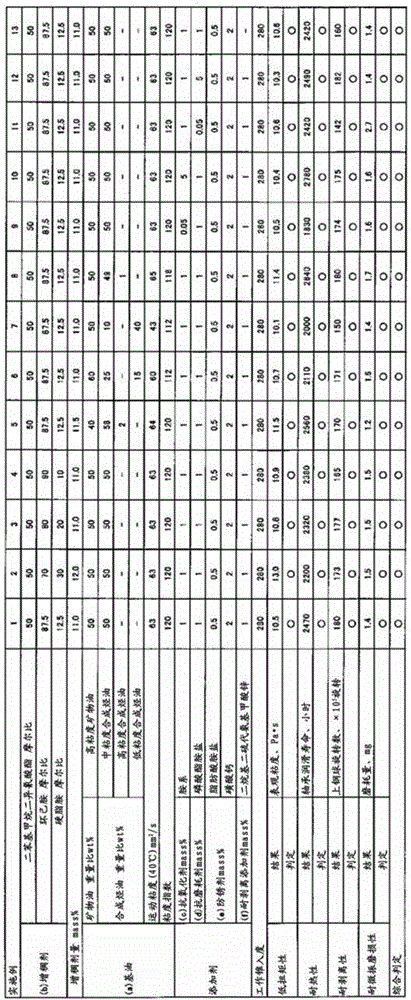

[0080] Grease compositions of Examples and Comparative Examples were prepared using thickeners and base oils shown in the following tables. Specifically, diphenylmethane diisocyanate (1 mole) was reacted with a predetermined amine (2 moles) in the following base oil, and after heating and cooling, three-roll rolling was carried out to measure the working penetration (test method JIS K2220 7.) The grease composition of Examples 1-11 and Comparative Examples 1-9 was obtained so that it may become 280. In addition, the kinematic viscosity of the base oil at 40 degreeC is measured according to JISK222023. In Table 1 and Table 2, the value of mass % represents the ratio relative to the total mass of the grease composition. The remainder is base oil. In Table 1 and Table 2, the weight ratio wt% of mineral oil represents the ratio of mineral oil to the total amount of mineral oil and synthetic hydrocarbon oil, and the weight ratio wt% of synthet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| penetration degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com