Grease composition for EV/HEV drive motor bearing, and EV/HEV drive motor bearing

A grease composition, a technology for driving motors, used in grease compositions, HEV drive motor bearings, EV fields, can solve problems such as poor heat resistance of base oil, and achieve long bearing lubrication life and excellent low temperature fluidity. Effect

Inactive Publication Date: 2014-04-16

NSK LTD +1

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the kinematic viscosity of the base oil is lowered, the low-temperature fluidity is satisfied, but the heat resistance of the base oil at a high temperature deteriorates, and the seizure life cannot be satisfied anymore.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0053] 〔Preparation of test grease〕

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| cone penetration | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

Login to View More

Abstract

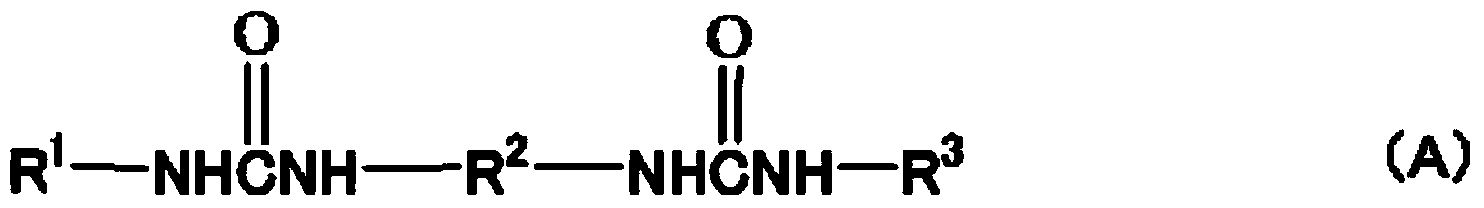

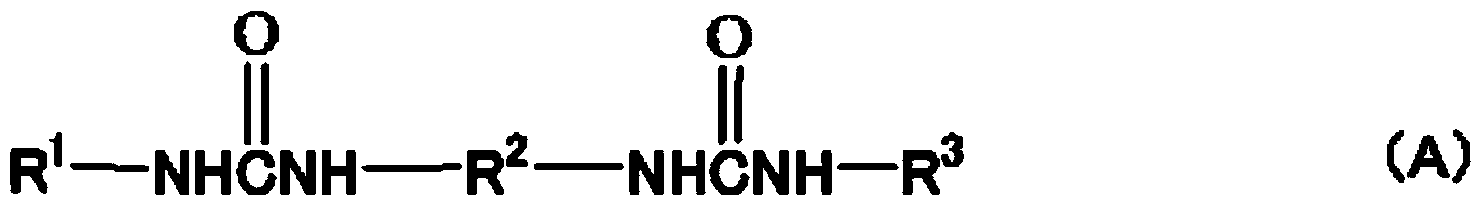

The present invention provides a grease composition for an EV / HEV drive motor bearing, the composition containing: a diurea thickener of formula (A) as well as a base oil containing at least 80 mass% of trimethylolpropane ester oil per the total mass of base oil, the dynamic viscosity of the base oil at 40 DEG C being 15 to 50 mm2 / s. (In the formula, R2 represents a C6-15 divalent aromatic hydrocarbon group. R1 and R3 are the same or different groups, and represent a C16-20 linear or branched alkyl group or cyclohexyl group, the proportion of the number of moles of the C16-20 linear or branched alkyl group relative to the sum of the numbers of moles of the C16-20 linear or branched alkyl group and the cyclohexyl group [{(number of alkyl groups) / (number of cyclohexyl groups + number of alkyl groups)} 100] being 60 to 80%.) This grease composition has a long bearing lubrication lifespan even at high temperature / high speed conditions, and satisfies low-temperature fluidity.

Description

technical field [0001] The present invention relates to a grease composition for EV and HEV drive motor bearings, and EV and HEV drive motor bearings enclosing the composition. Background technique [0002] Support bearings for drive motors used in electric vehicles (EVs) and hybrid vehicles (HEVs) are used in various environments ranging from low-temperature atmospheres in cold regions to high-temperature atmospheres caused by electric motors, transmissions, and reducers Therefore, it is required to be used in a wide temperature range. In addition, high-speed rotation is promoted along with high output of electric motors, and durability under high-speed rotation is required for bearings used in order to improve rotation performance. [0003] On the other hand, from the viewpoint of a high-temperature operating environment, a long seizing life is required for the grease used. For the grease with mineral oil as base oil and the grease with lithium soap as thickener, due to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/02C10M105/38C10M115/08C10M129/10C10M133/12C10M159/24F16C33/66C10N20/00C10N20/02C10N30/00C10N30/02C10N30/06C10N30/10C10N40/02C10N50/10

CPCC10M169/02C10M2215/064C10M115/08C10M2205/0285C10M2203/1006C10M2207/2835C10M2219/046C10M129/10C10N2230/02F16C33/6633C10M2215/1026C10M2207/289C10M105/38C10M159/24C10M135/10C10N2230/06C10N2250/10C10N2220/022C10N2240/02C10M2207/026C10M133/12C10M2207/0406C10M2207/2825C10N2020/02C10N2030/02C10N2030/08C10N2030/06C10N2040/02C10N2050/10

Inventor 水城宏教前岛武始矶贤一中川和纪今井裕相田亮

Owner NSK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com