Fast Heating Control Algorithm for Wire-Mesh Reactor with Adjustable Heating Rate

A technology of control algorithm and heating rate, applied in auxiliary controller with auxiliary heating device, temperature control using electric method, etc., can solve the problem of inability to achieve continuous and flexible adjustment of heating rate, long stability time, and rapid adjustment. problems such as falling, to achieve fast and stable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

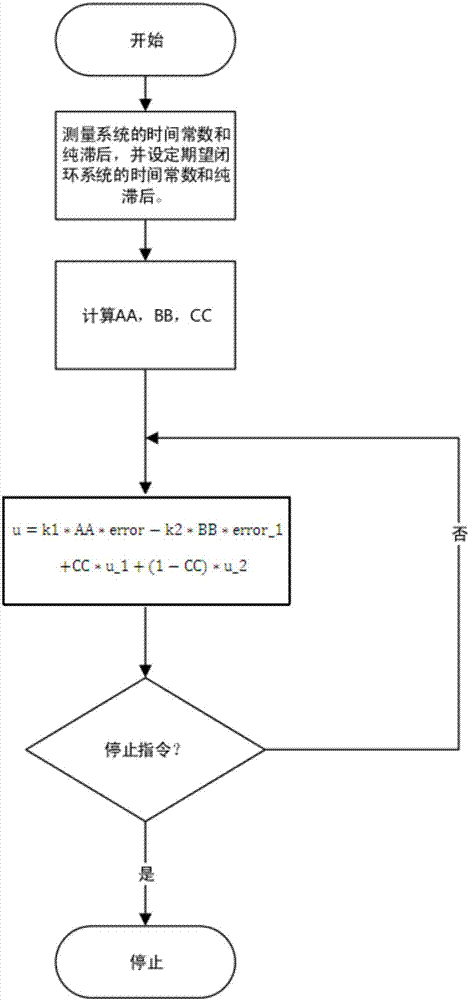

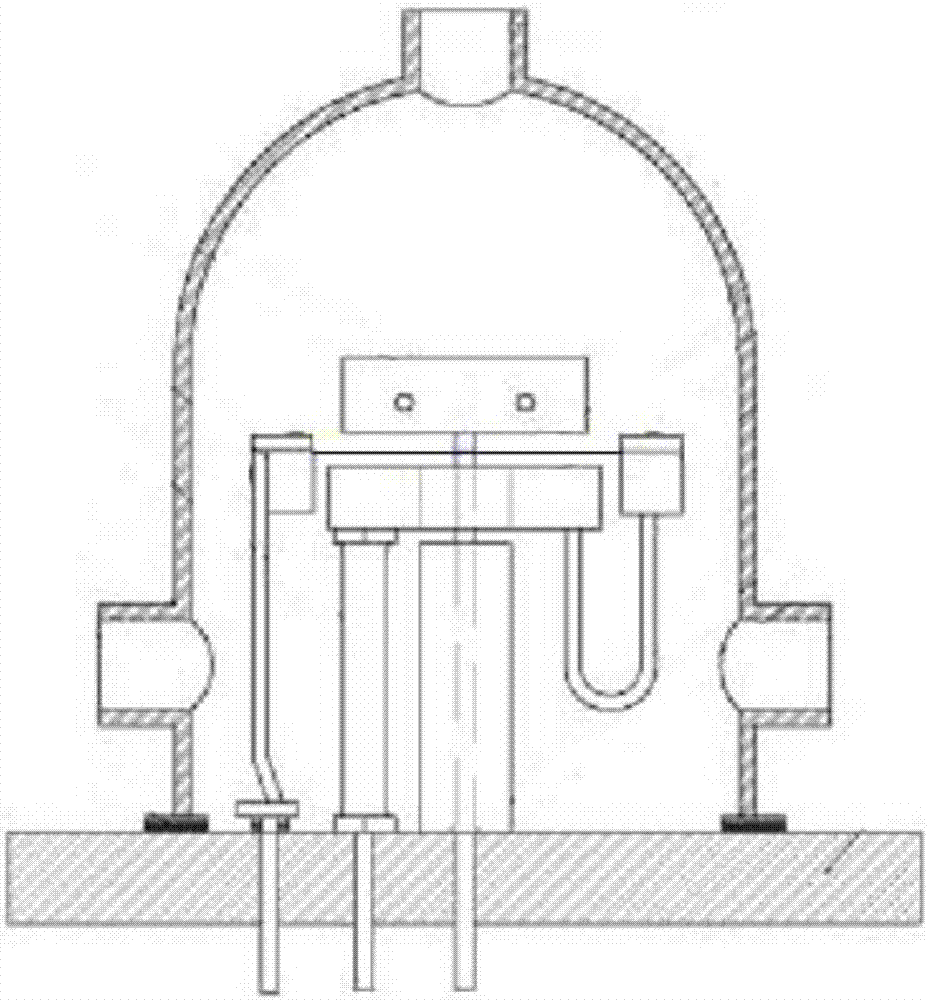

[0032] The embodiments will be described in detail below in conjunction with the accompanying drawings.

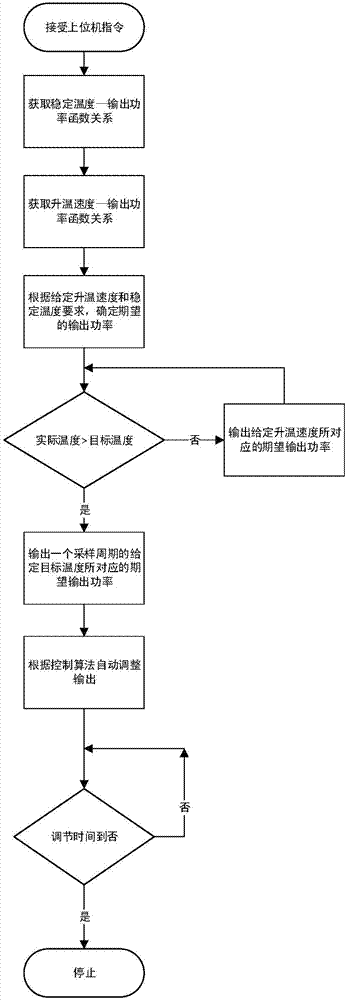

[0033] The present invention proposes a temperature rise control algorithm in which the temperature rise rate of a wire mesh reactor is continuously and flexibly adjustable, and the temperature rise mode can be selected. The overall control algorithm flow is as follows: figure 1 as shown,

[0034] Step 1. Determine the sampling speed according to the hardware performance.

[0035] The sampling speed depends on the performance of the hardware constituting the control system. It mainly involves the performance of the temperature transmitter and the performance of the actuator. The sampling speed should be slightly greater than the response time of the temperature transmitter and actuator. The sampling period should be much smaller than the time constant of the object, otherwise the transient process cannot be reflected; at the same time, the adjustment quality required by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com