Method for measuring jack height of turbo generator set based on TSI system

A turbo-generator set, height measurement technology, applied in the direction of electric/magnetic thickness measurement, electromagnetic measurement device, etc., can solve the problems of large human error, low safety, difficult operation, etc., to increase reliability, improve measurement accuracy, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

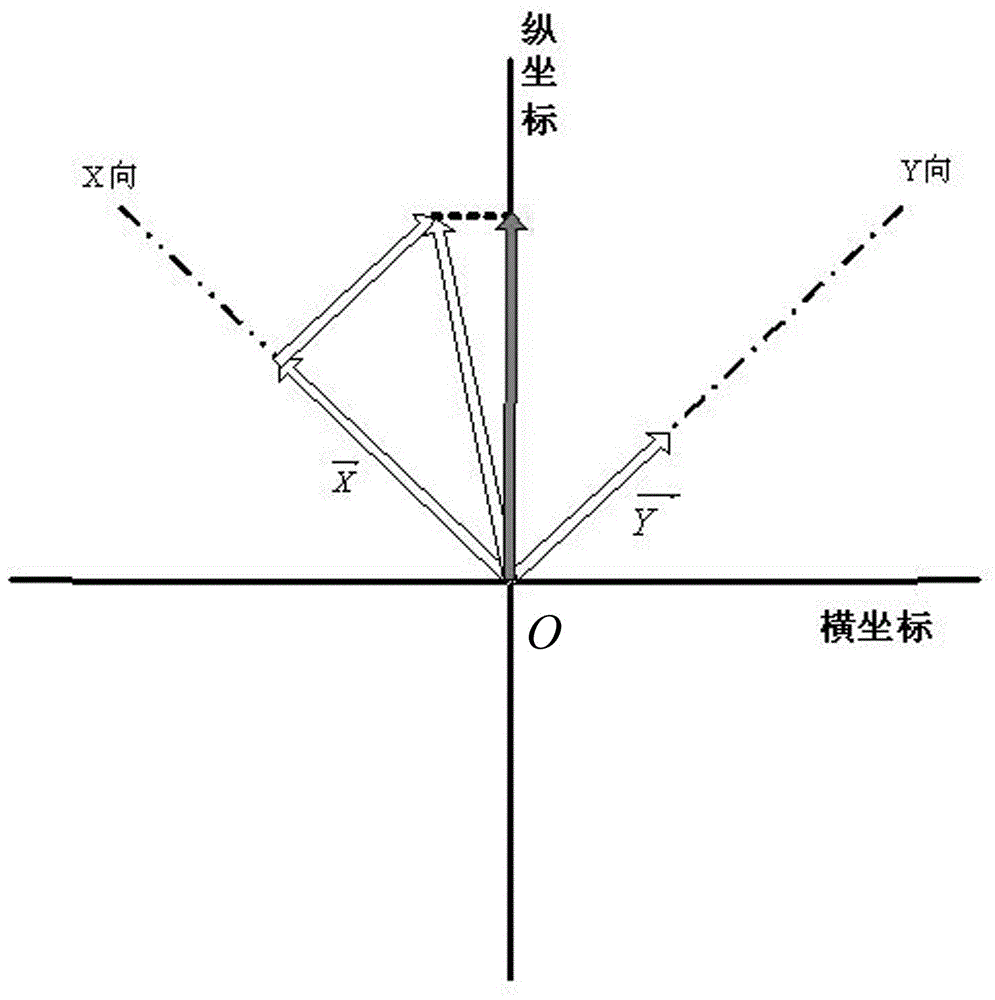

[0020] Shut down the unit, stop the shafting of the unit, put the lubricating oil system into operation, and start the TSI system in sequence. Then stop the jacking shaft oil pump, measure and record the output voltage U of the shaft vibration sensor in the X and Y directions X0 =-11.000V, U Y0 =-10.900V. Start the jacking shaft oil pump, measure and record the output voltage U of the shaft vibration sensor in the X and Y directions after the operation is stable X1 =-10.700V, U Y1 =-10.700V, calculate the voltage change U X1 -U X0 =0.3V, U Y1 -U Y0 =0.2V; According to the sensitivity coefficient α of X-direction and Y-direction axial vibration sensor X =8V / mm, α Y =8V / mm converts the voltage change into displacement change|X|=|(U X1 -U X0 ) / α X |=0.0375mm, |Y|=|(U Y1 -U Y0 ) / α Y |=0.025mm.

[0021] Take the horizontal mid-section of the bearing bush as the abscissa, the vertical mid-section as the ordinate, and the intersection point of the abscissa and y-coordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com