Building type absorption heat exchange station

A heat exchange station and absorption technology, applied in the field of building-type absorption heat exchange stations, can solve problems such as inability to realize separate building heating, achieve the effects of reducing energy consumption in transmission and distribution, avoiding thermal imbalance, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention in detail, embodiments of the exemplary embodiment illustrated in the accompanying drawings. The embodiments described below are illustrative of the invention, and is intended to be construed as limiting the invention.

[0025] Detailed Description Building formula miniaturized absorption heat transfer station according to embodiments of the present invention in conjunction with the following drawings.

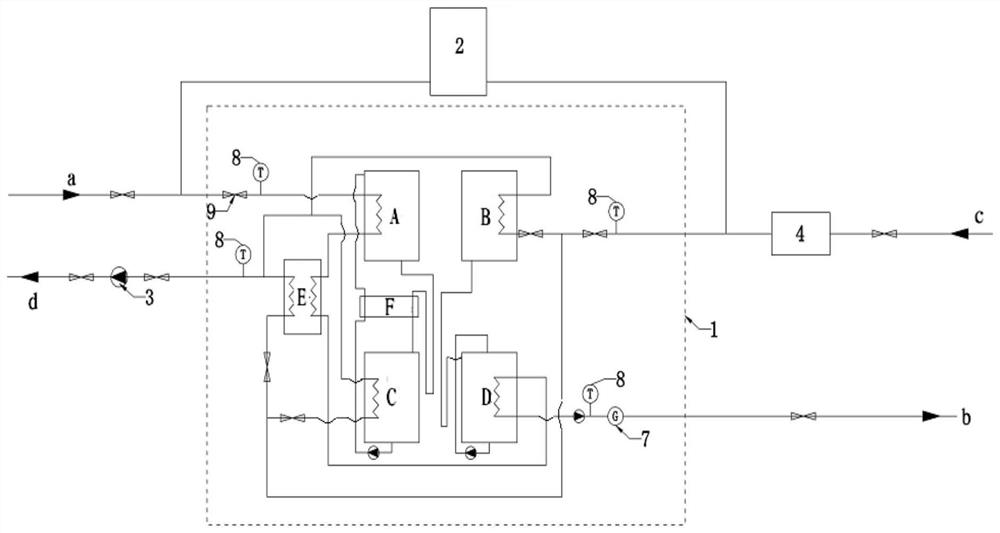

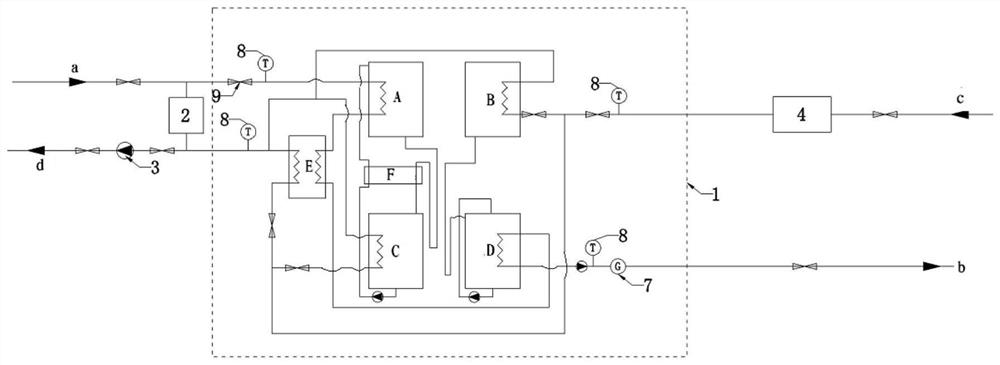

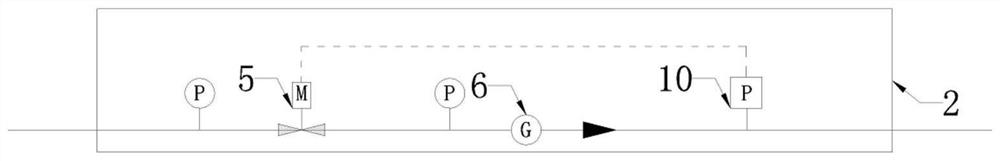

[0026] figure 1 Shows a building in accordance with one embodiment of Formula absorption heat transfer station embodiment of the present invention. Refer figure 1 , According to an embodiment of the building type heat exchanger of the present invention, the absorption by the absorber heat exchanger station 1, replenishment constant pressure device 2, the second circulation pump 3 and the primary network and the secondary network station sea water composition for the integrated transducer thermal stations, to achieve a net heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com