Stair concrete pouring formwork device and stair concrete pouring method

A technology for concrete and stairs, applied in the direction of formwork/formwork/work frame, building, building structure, etc., can solve the problems of long construction time affecting the normal construction period, time-consuming demolition, concrete surface damage, etc., to achieve convenient installation and demolition , It is convenient for carpentry and bricklayer construction, and the effect of concrete forming is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

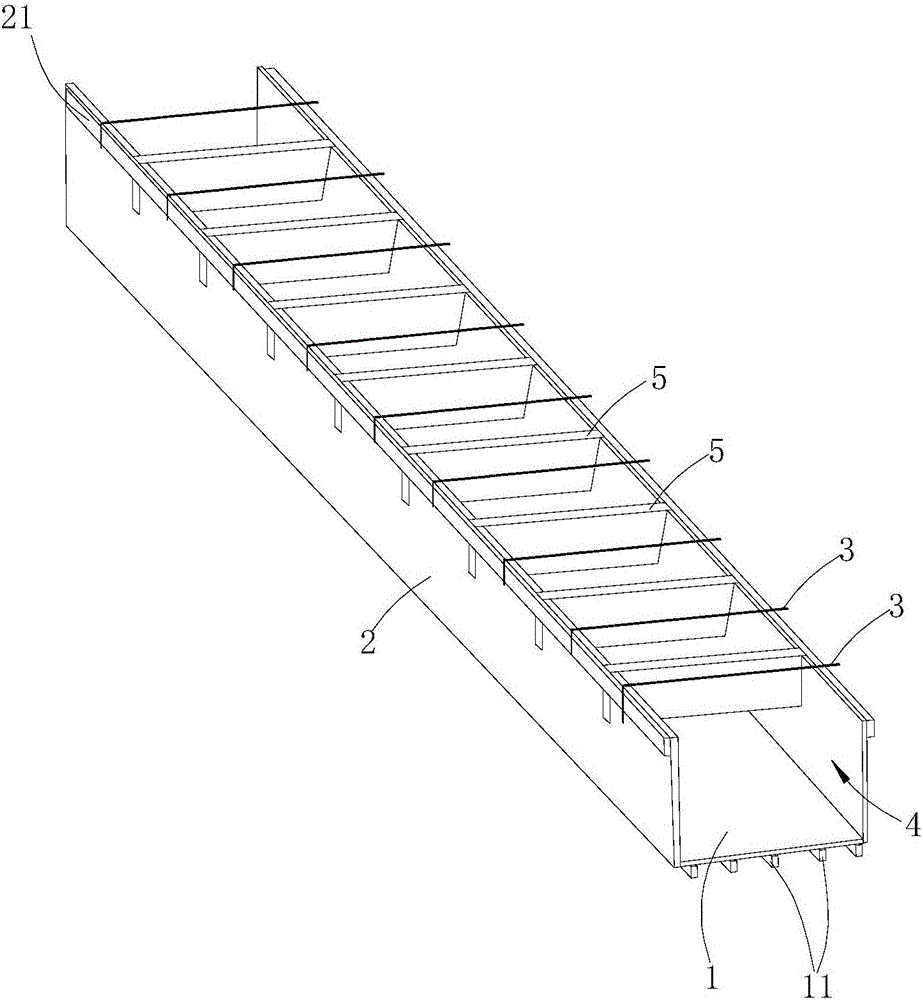

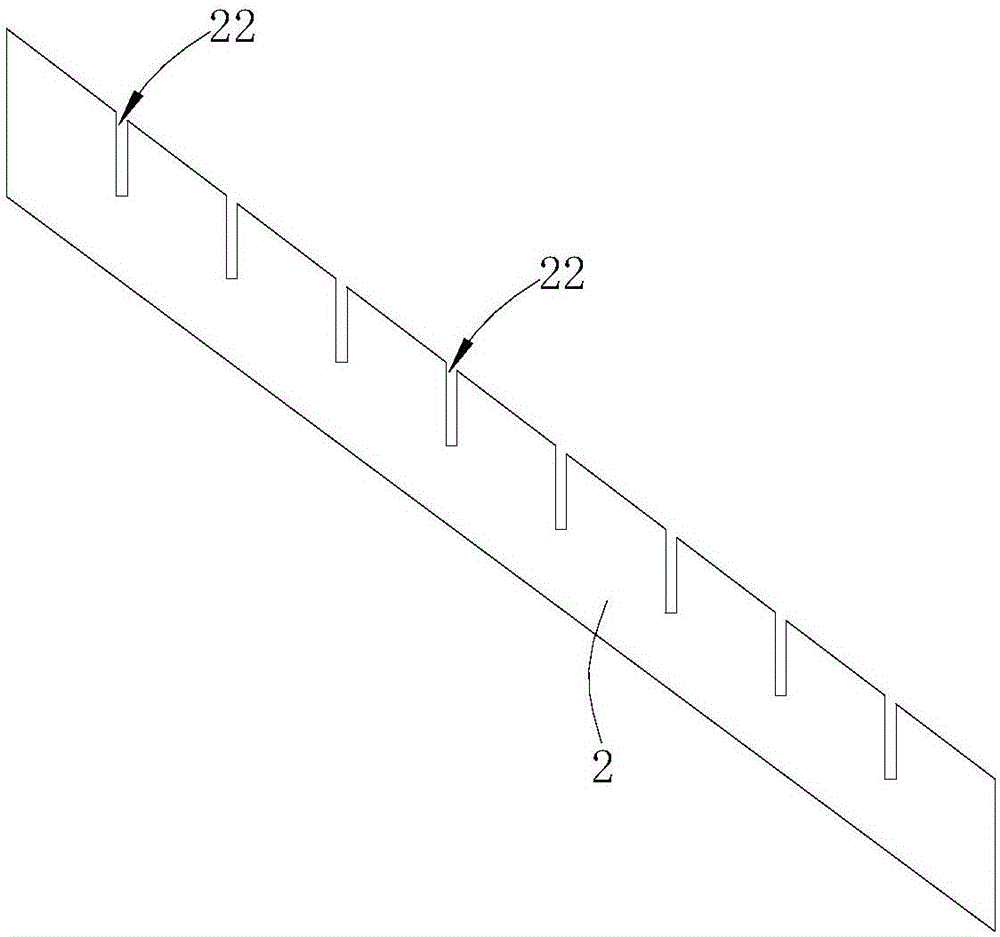

[0025] Such as Figures 1 to 2 as shown ( figure 2 Ribs are omitted in 21)

[0026] The formwork device comprises a bottom formwork 1, two side formworks 2 and a plurality of transverse baffles 5.

[0027] The bottom template 1 is a rectangular thin plate, and the back of the bottom template 1 is provided with a plurality of square wooden keels 11, and the multiple square wooden keels 11 are arranged along the width direction of the bottom template 1, and the adjacent two square wooden keels 11 are arranged at intervals. The two sides of the formwork 1 are placed between the upper and lower adjacent floor conversion platforms respectively.

[0028] The two side formworks 2 have the same structure, they are all rectangular thin plates, each side formwork 2 is nailed with a square wood-like reinforcing rib 21 on the upper edge, and each side formwork 2 is respectively provided with a plurality of vertical plates along its length direction. The straight slot notches 22 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com