Full-automatic under-cover filling production line for binary bag aerial fog filling

A fully automatic, production line technology, applied in the direction of packaging objects, packaging, transportation and packaging under special gas conditions, it can solve the problem of not being able to fill 152a gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

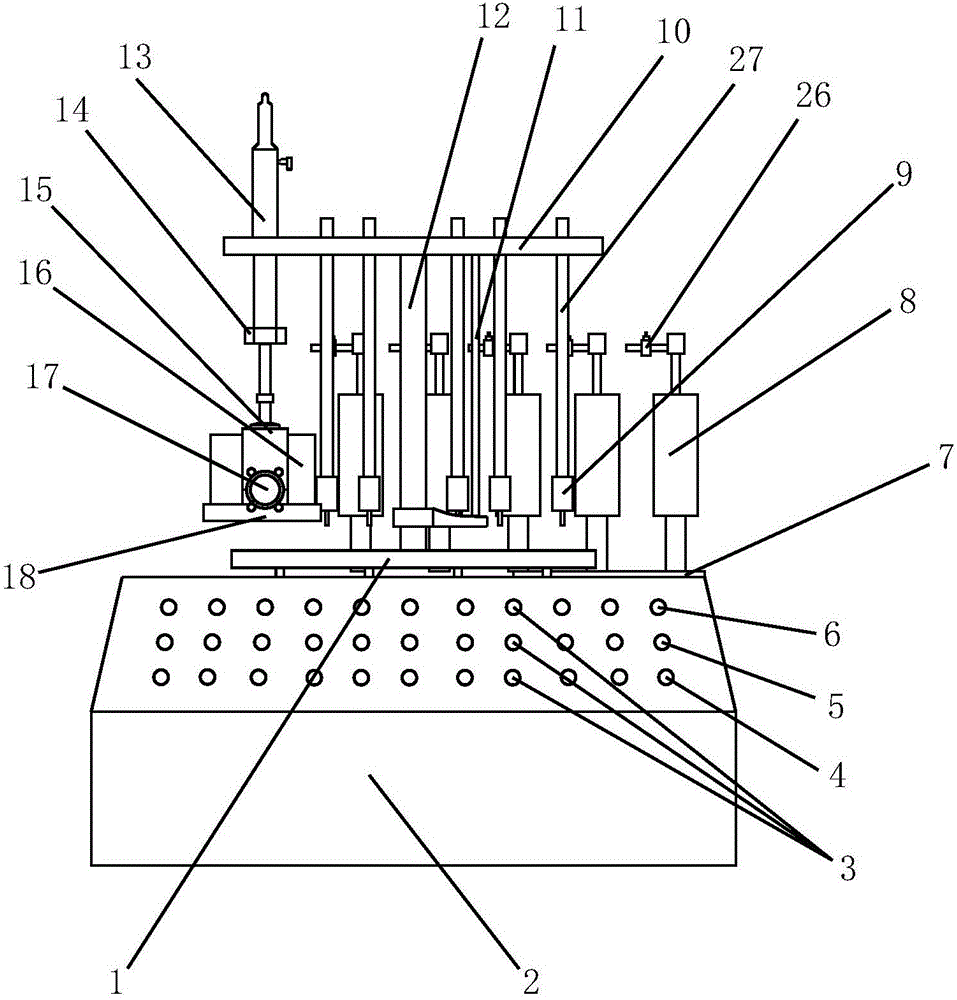

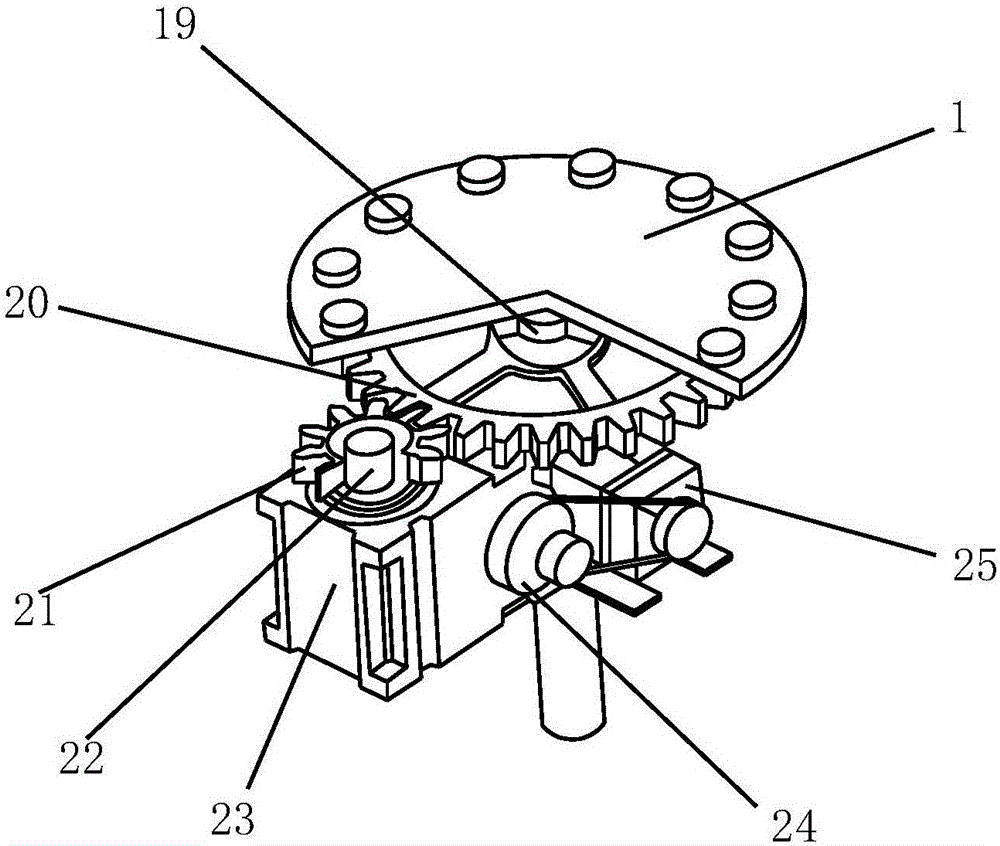

[0020] as attached Figure 1-2 As shown, a full-automatic under-cap filling production line for binary bag aerosol filling includes a frame 2, a power device is arranged inside the frame 2, a station turntable 1 is arranged on the upper end surface of the frame, and the power device and The transmission connection between the station turntables 1 is carried out through an indirect transmission device. Described indirect transmission device comprises the pneumatic clutch 24 that is arranged in the frame 2 and is connected with power unit transmission, and starting clutch 24 is connected with high-precision station indexing device 23 through drive belt transmission, and high-precision station indexing device 23 transmission is connected with Rotating shaft 22, the end key of rotating shaft 22 is connected with transmission gear 21, and transmission gear 21 meshes with interlocking gear 20, and interlocking gear 20 is keyed with transmission shaft 19, and transmission shaft 19 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com