Propeller with blade tip vibration and for vibration attenuation and noise reduction ship

A marine propeller, vibration and noise reduction technology, applied in the direction of rotating propellers, rotating propellers, etc., can solve the problems of high vibration and high noise, and achieve the effect of improving dynamic performance, simple design ideas, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

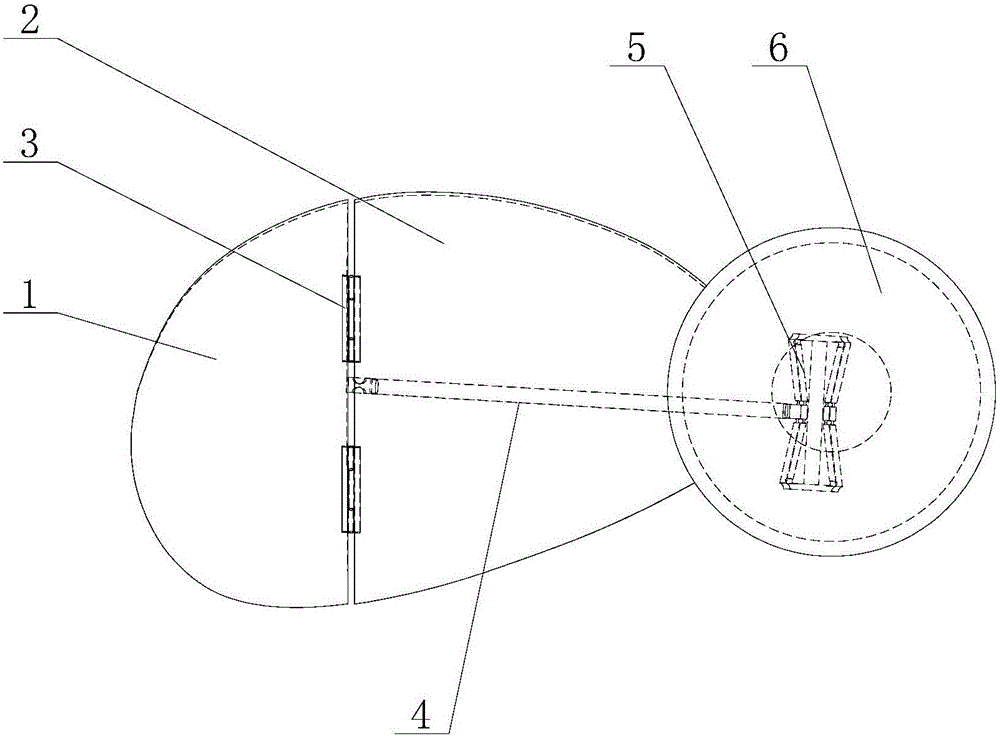

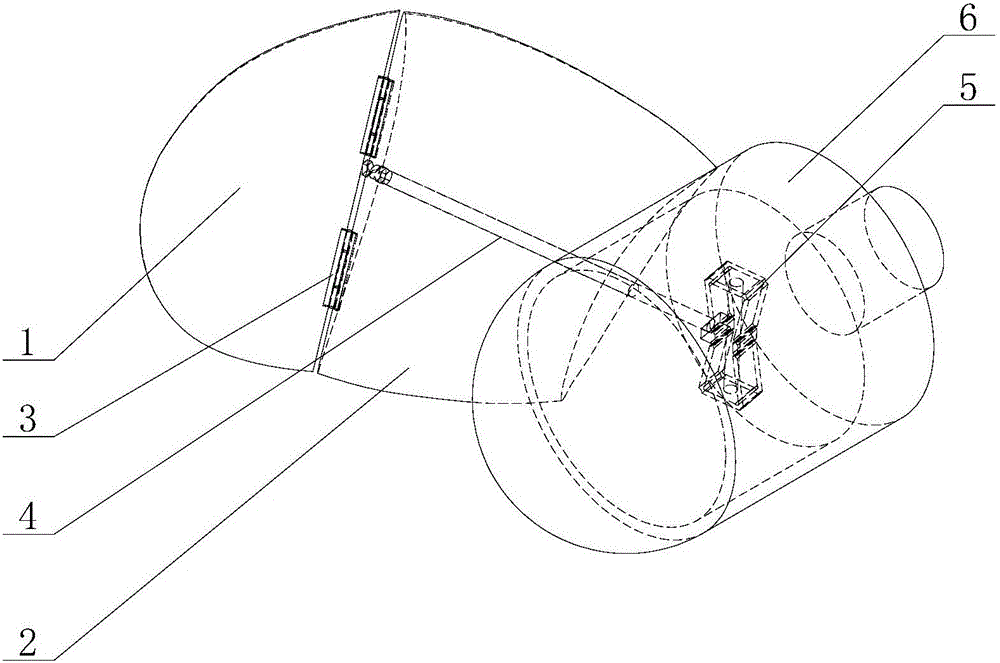

[0009] Specific implementation mode one: combine figure 1 with figure 2 This embodiment is described. The vibration and noise reduction marine propeller of blade tip vibration described in this embodiment includes a hub 6 and a plurality of blades, and the plurality of blades are evenly distributed on the propeller along the circumferential direction of the hub 6. On the outer wall of the hub 6, this embodiment also includes a plurality of rotary hinges 3, a plurality of driver displacement transmission rods 4 and a plurality of drivers 5, each of the blades is composed of a blade tip 1 and a blade body 2, and the blade The tip 1 is connected to the blade main body 2 through two rotating hinges 3 , a plurality of drivers 5 are installed in the hub 6 , and each driver 5 is connected to a corresponding blade tip 1 through a driver displacement transmission rod 4 .

[0010] In this embodiment, the periodic displacement generated by the driver 5 is transmitted to the blade tip 1...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 with figure 2 The present embodiment is described. The blade tip 1 and the blade main body 2 of the vibration-damping and noise-reducing marine propeller of the blade tip vibration described in this embodiment are both made of resin-fiber composite material. In this embodiment, the blade tip 1 can reciprocate around the rotary hinge 3 , and this structure can largely ensure the flexibility of the blade tip 1 to swing. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 with figure 2 The present embodiment is described. Each blade tip 1 of a marine propeller with vibration reduction and noise reduction for blade tip vibration described in this embodiment is provided with a displacement sensor and a speed sensor.

[0016] The technical effect of this embodiment is: so set, the displacement sensor and the speed sensor can detect the initial vibration signal of the propeller blade tip 1 and the signal after noise reduction at any time, and the control system can be controlled by initial monitoring and real-time feedback to the control system. Monitor the overall status of the current propeller at all times. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0017] working principle

[0018] The driver 5 transmits the periodic displacement to the blade tip 1 through the driver displacement transmission rod 4, which causes the blade tip 1 to generate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com