Variable-temperature circulating system and variable-temperature circulating method of injection mold

A technology of injection mold and circulation system, which is applied in the variable temperature circulation system and the field of variable temperature circulation of injection molds, and can solve problems such as shrinkage, obvious weld lines, and internal stress that cannot be eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

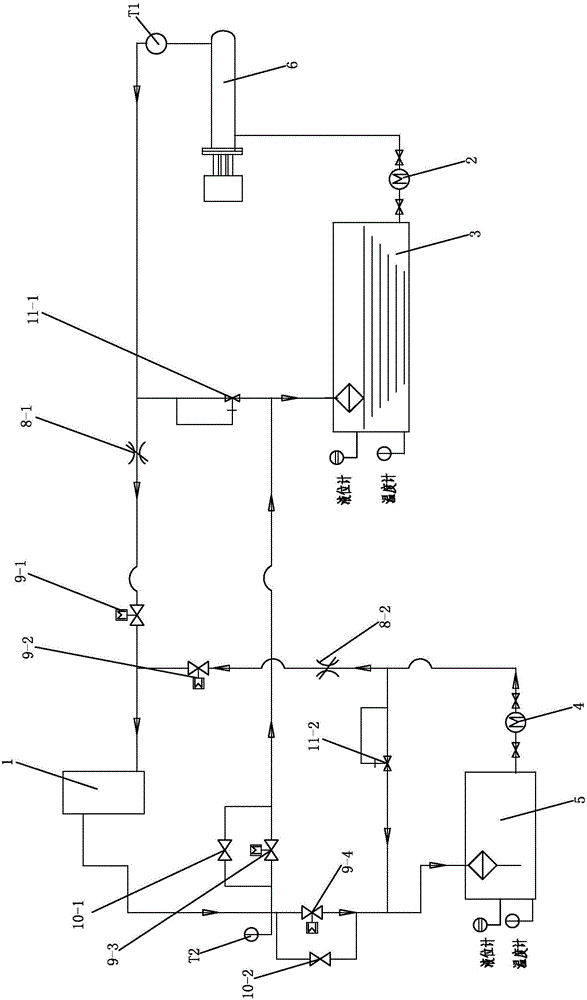

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] see figure 1 , a temperature-variable circulation system for an injection mold, comprising a thermal oil circulation module and a cold oil circulation module, the thermal oil circulation module comprising a thermal oil tank 3, a thermal oil pump 2, an electric heater 6, a first thermometer T1, a thermal Oil flow regulating valve 8-1, first solenoid valve 9-1, heating equipment 1, third solenoid valve 9-3, third solenoid valve 9-3 is connected to hot oil tank 3 through oil pipe, third solenoid valve 9 -3 is connected in parallel with the first manual control valve 10-1; the cold oil circulation module includes a cold oil tank 5, a cold oil pump 4, a cold oil flow regulating valve 8-2, a second electromagnetic valve 9-2, and a heat Equipment 1, the second thermometer T2, the fourth solenoid valve 9-4, the fourth solenoid valve 9-4 is connected to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com