A tool and method for disassembling and assembling multifunctional online corrosion monitoring probes

A corrosion monitoring and multi-functional technology, applied in the field of tools for disassembling and assembling multi-functional online corrosion monitoring probes, can solve the problems of inability to repair and replace corrosion monitoring probes, achieve safety and practicability, and protect the safety of operators. , the effect of improving work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

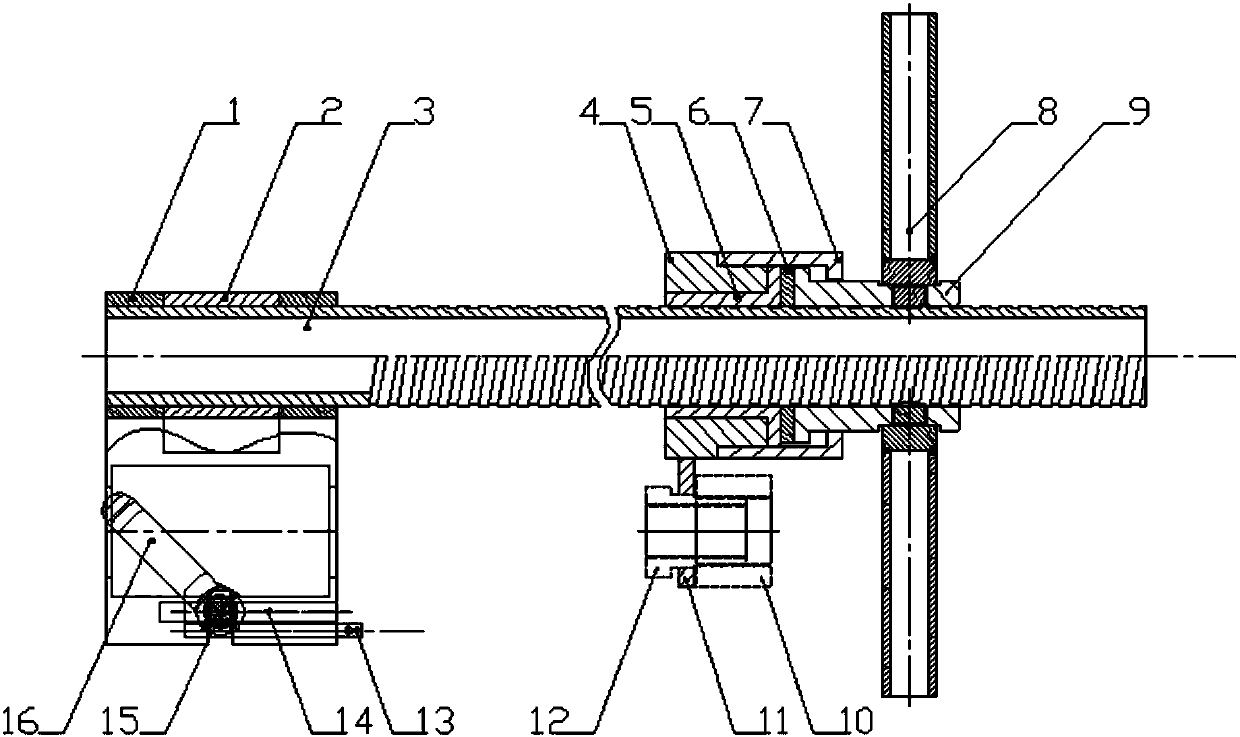

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

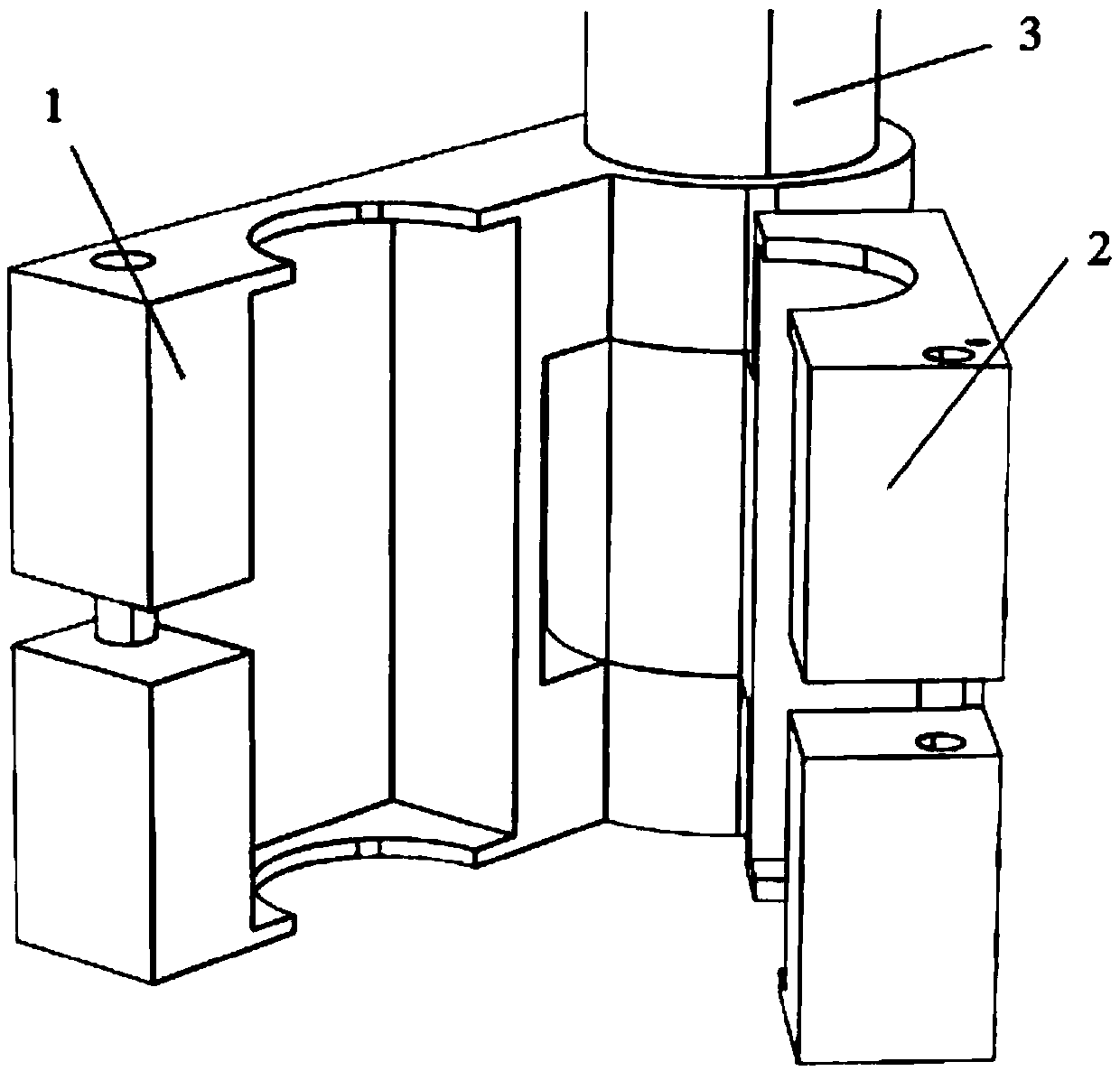

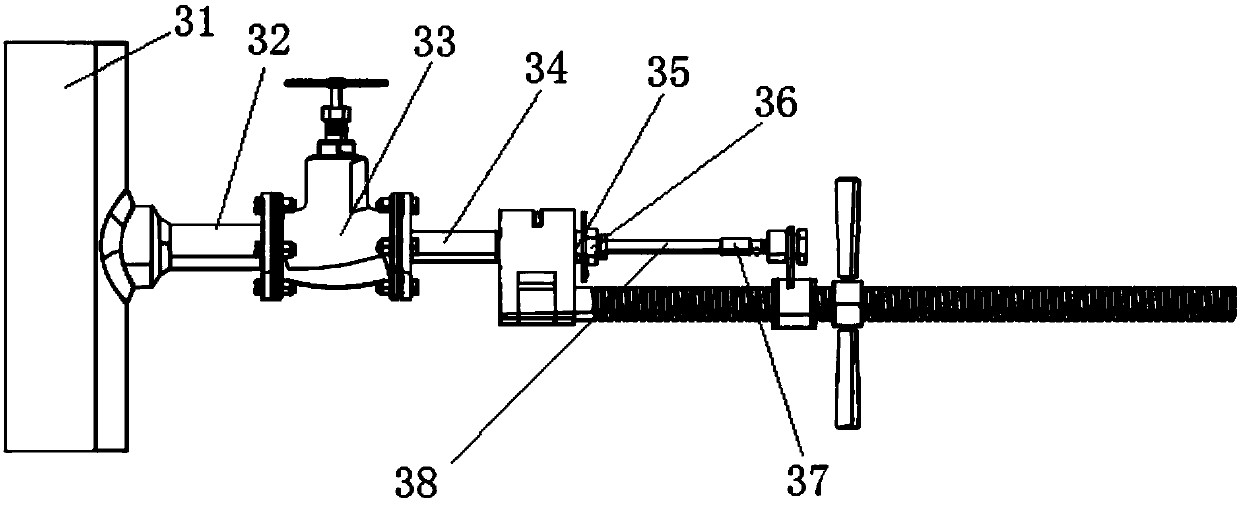

[0032] Such as figure 1 , 2 As shown, the present invention is used for the dismounting tool of multifunctional on-line corrosion monitoring probe, has lead screw 3, lead screw fixing seat and positioning assembly, and wherein lead screw 3 end is installed with lead screw fixing seat, and lead screw fixing seat is The split structure cooperates with the sealing stuffing box 35 of the corrosion monitoring probe 38; the positioning component is slidingly connected with the lead screw 3 through the set, and the positioning component is provided with a connecting piece that can be connected with the corrosion monitoring probe 38.

[0033] The screw fixing base includes a first screw fixing base 1 and a second screw fixing base 2, the parts where the screw is connected to the two fixing bases have no thread, wherein the first screw fixing base 1 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com