Rotary vibrating screen

A technology of rotary vibrating sieve and screen mesh, which is applied in the direction of filter screen, solid separation, grid, etc., which can solve the problems of uneven screening and uneven travel, achieve uniform screening, reduce excessive gaps in motion travel, increase The effect of large processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

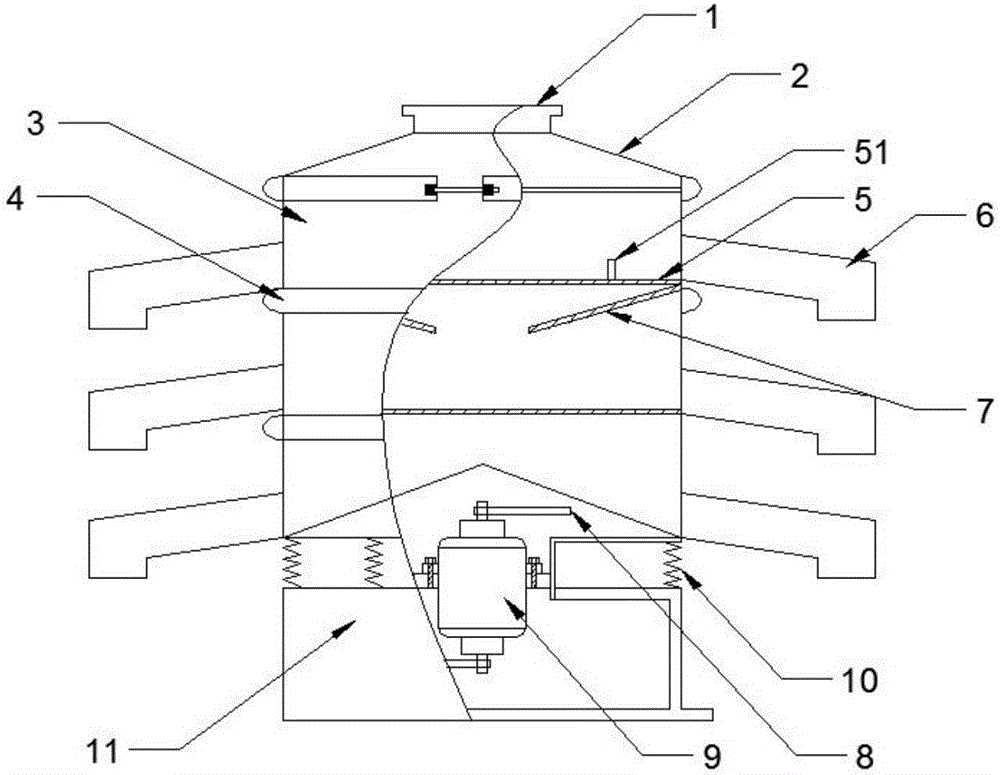

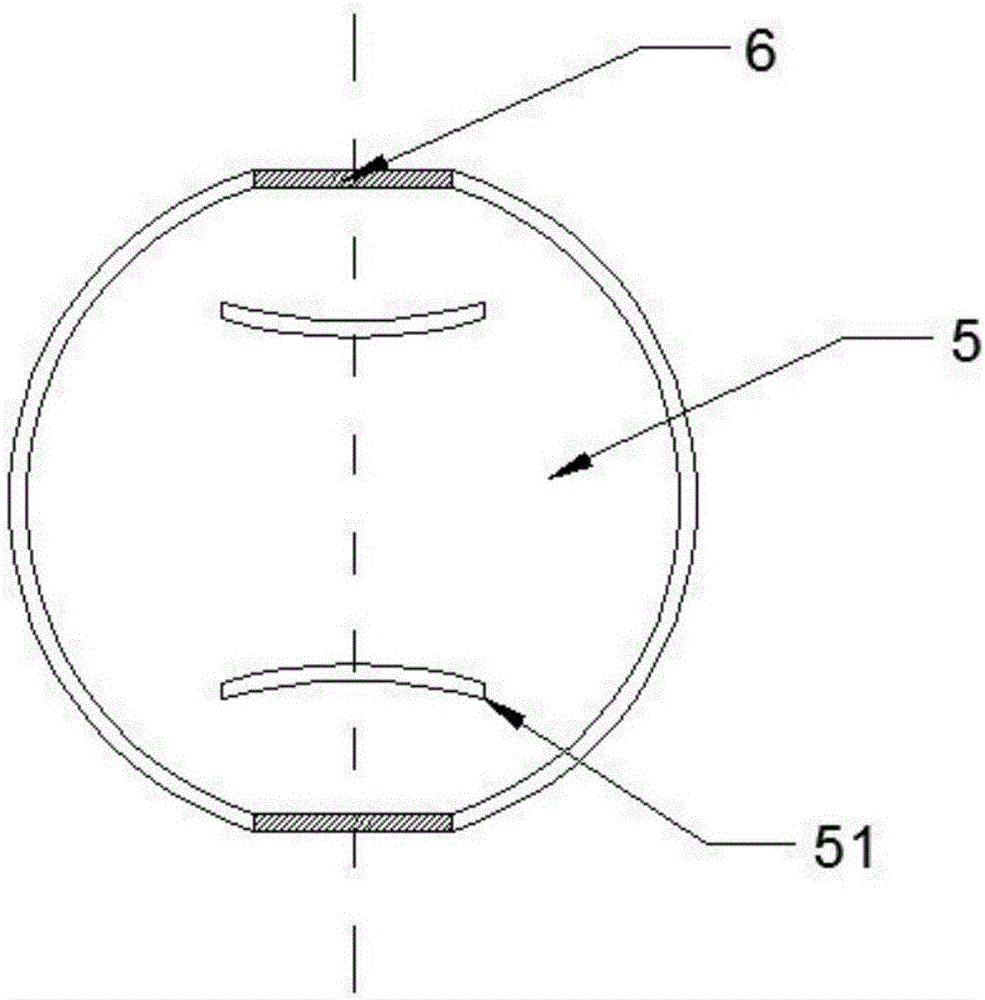

[0012] like figure 1 , figure 2 The rotary vibrating screen shown includes feed inlet 1, dust cover 2, screen frame 3, beam ring 4, screen mesh 5, discharge port 6, return plate 7, weight 8, vibration motor 9, spring 10 , machine base 11, baffle plate 51.

[0013] The feed inlet 1 is arranged on the top of the dustproof cover 2, and the dustproof cover 2 is conical; the screen frame 3 is cylindrical and hollow, and the screen mesh 5 is circular, and the screen frame 3 and the screen mesh 5 are combined to form a layer of sieve Layer, a sieve layer is a cylinder, which is the basic unit of sieving. The dust cover 2 and the screen layer are connected and fixed by the beam ring 4; the discharge port 6 is arranged on both sides of the screen layer, which are symmetrical to each other; The material falls to the center of the lower screen 5, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com