Cutting thread-free down jacket and manufacturing method thereof

A production method and technology for down jackets, applied in the field of down products, can solve the problems of reducing the beauty of down jackets, affecting the beauty of clothes, damage to fabrics, etc., and achieving the effects of increasing the ability to prevent fleece, increasing the beauty and being widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

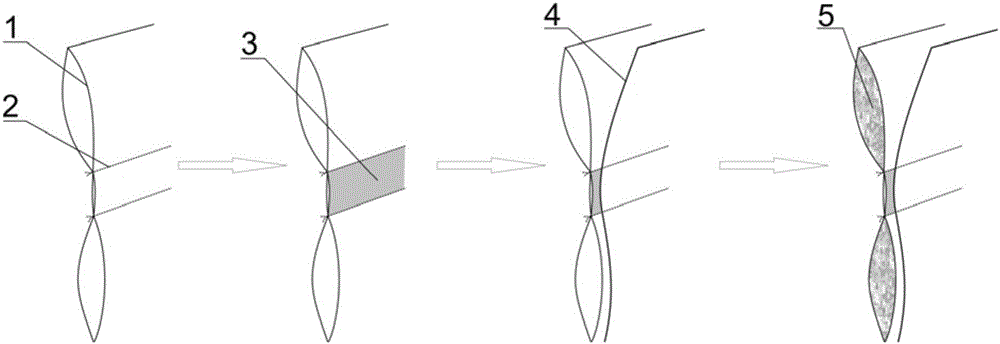

[0028] A kind of tangent-free down jacket, the production process of the down jacket is as follows: figure 1 As shown, it specifically includes the following steps:

[0029] (1) Select a double-layer fleece-proof lining 1, and cut double quilting lines 2 on the double-layer fleece-proof lining 1, and cut through the double-layer fleece-proof lining 1 by the double quilting lines 2;

[0030] (2) Paste the double-sided tape 3 for clothing on one side of the double-layer anti-velvet lining 1. The distance between 2 is equal;

[0031] (3) pressing the double-sided adhesive tape 3 so that the double-sided adhesive tape 3 is bonded to the double-layer fleece-proof lining 1;

[0032] (4) The other side of the double-sided tape 3 is bonded to the inner surface of the down jacket fabric 4, and the bonding place is pressed with a high-frequency pressing machine, the pressing temperature is 145° C., and the pressing time is 10 seconds;

[0033] (5) Down 5 is filled between the double-...

Embodiment 2

[0036] In this embodiment, the pressing temperature of the high-frequency pressing machine is 140° C., and the pressing time is 15 seconds, and the rest are the same as in Embodiment 1.

Embodiment 3

[0038] In this embodiment, the pressing temperature of the high-frequency pressing machine is 150° C., and the pressing time is 5 seconds, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com