Diaphragm Valve

A technology of diaphragm valves and diaphragms, applied in the direction of diaphragm valves, diaphragms, valve details, etc., can solve problems such as large friction, difficulty, and limit the lateral size of the valve driver, and achieve the effect of small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

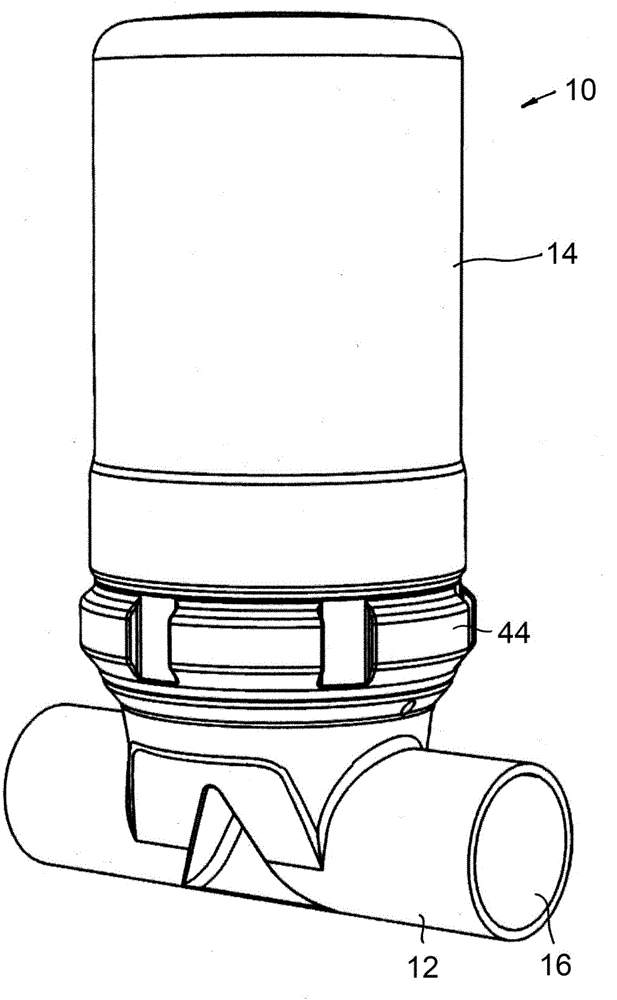

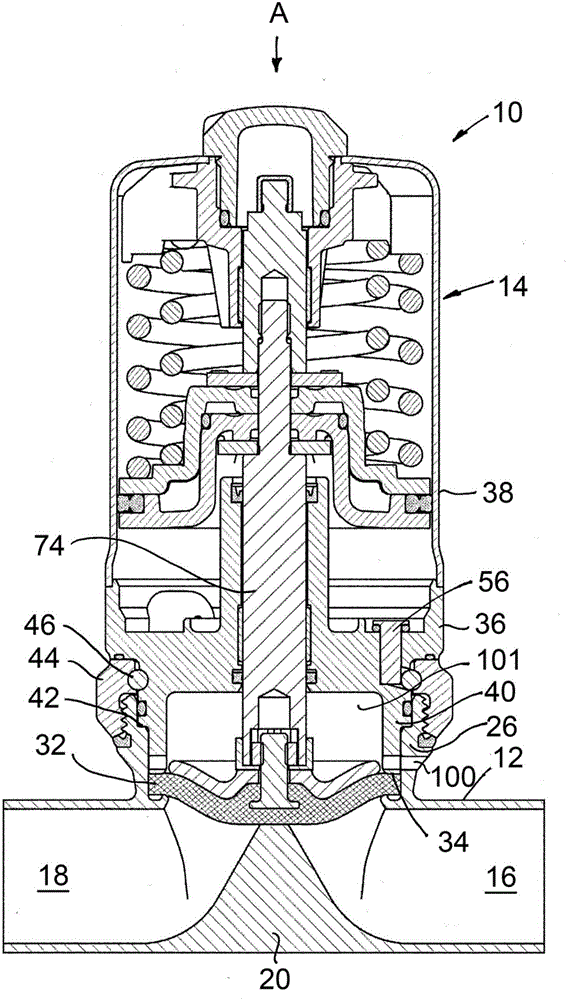

[0037] exist figure 1 A diaphragm valve 10 is shown in , which has a valve body 12 , here in the form of a tube, and a valve drive 14 fastened to the valve body 12 .

[0038] In this embodiment, the valve body is tubular as described and has a flow channel inside it, in which the figure 1 Exit 16 can be seen in . The flow passage can be selectively interrupted or opened in the valve body 12 by the valve driver 14, thereby closing or opening the valve.

[0039] Preferably, this should not be construed as limiting, the valve body 12 may be a one-piece part, deformed or manufactured by casting. Metal or plastic can be used as material.

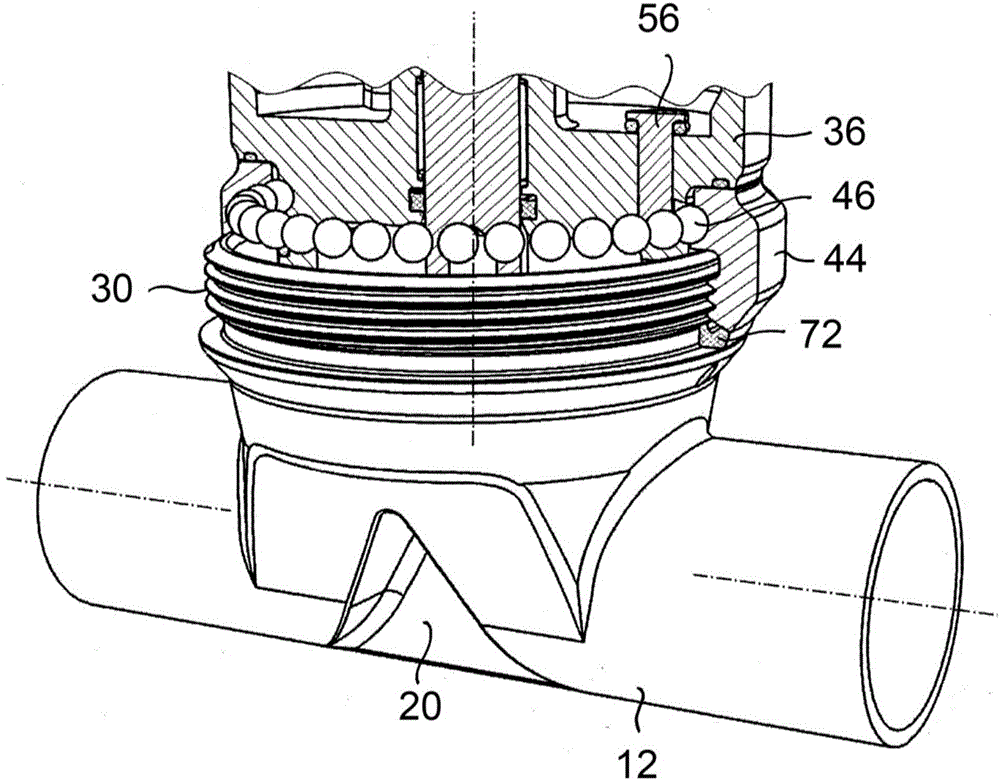

[0040] exist figure 2 In addition to the outlet 16, the inlet 18 of the flow channel can also be seen. A spacer tab 20 extends laterally into the flow channel between the inlet 18 and the outlet 16 and divides the flow channel into two sections. The upper side 22 of the spacer tab (Absperrsteg) 20 (see Figure 6 ) outwards to the pipe axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com