Flat extrusion container capable of reducing stress concentration of extrusion container

A stress concentration, flat extrusion cylinder technology, applied in the direction of metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problems of stress concentration, easy cracking, etc., to reduce the maximum stress and reduce the cost of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

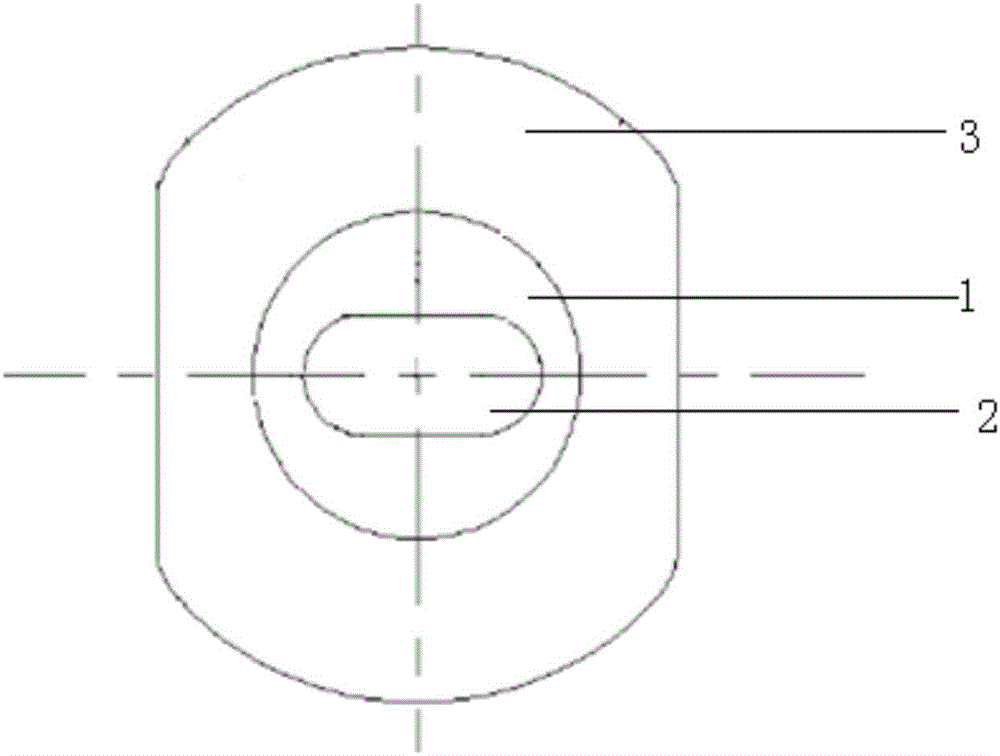

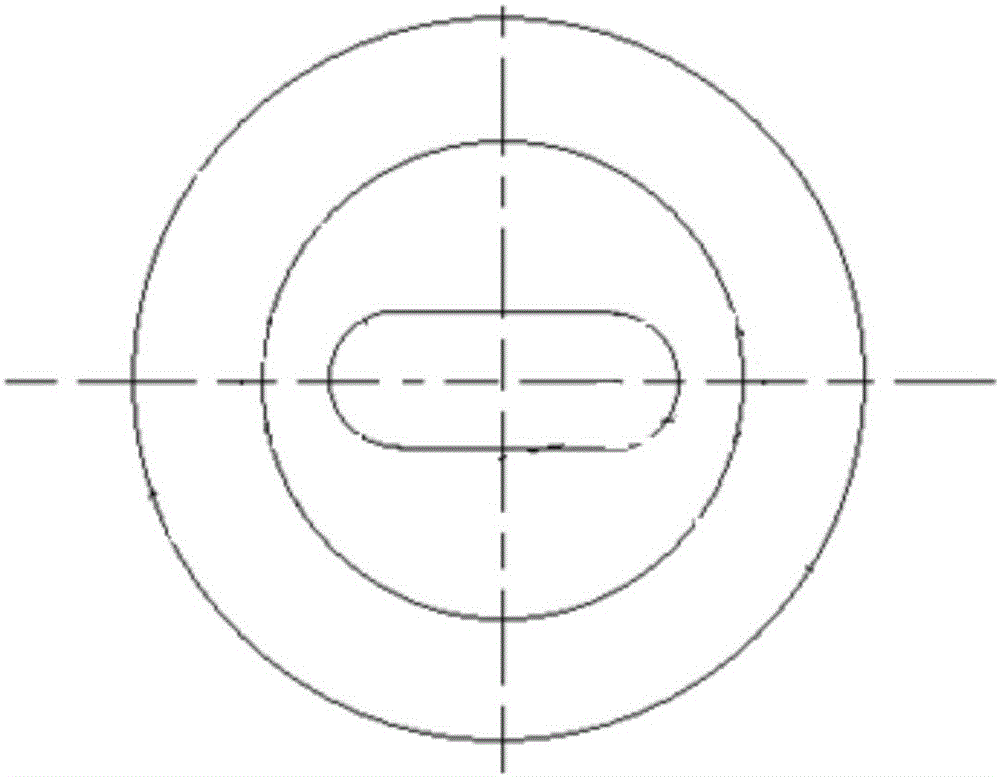

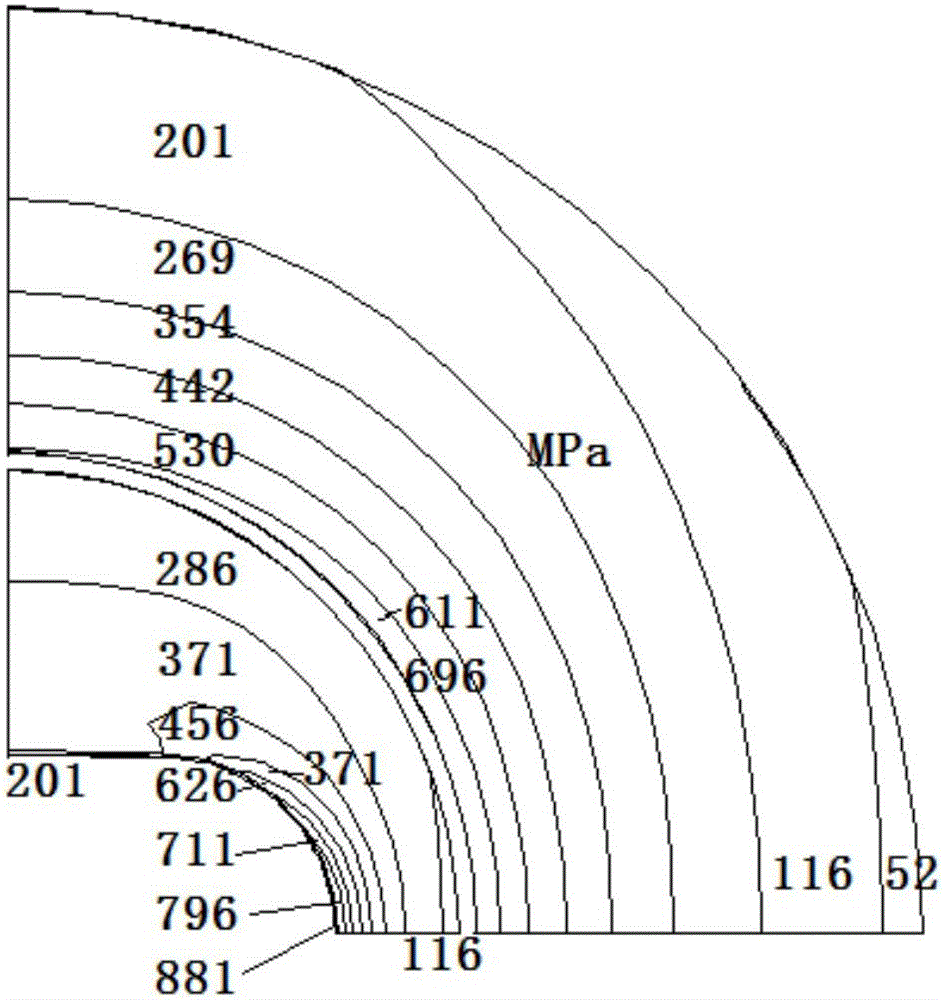

[0020] The structure of a flat extrusion cylinder that can reduce the stress concentration of the extrusion cylinder in the present invention is as follows: figure 1 As shown, it includes a circular inner sleeve 1, the middle part of the inner sleeve 1 is provided with an extrusion flat hole 2, the axis of the extrusion flat hole 2 is collinear with the axis of the inner sleeve 1, and the inner sleeve 1 is provided with an outer sleeve 3, and the outer sleeve 3 and the inner sleeve Interference fit between 1, the outer contour of jacket 3 is composed of two parallel straight lines and two elliptical arcs, its geometric shape is flat oval, and its outer contour is composed of two parallel straight lines and two arcs: two upper and lower The parallel line is connected with two left and right circular arc lines, and the left and right circular a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com