Assembly machine for double-wing intravenous needle catheters

A technology for venous needles and assembly machines, which is applied in the direction of needles, measuring devices, optical devices, etc., can solve the problems of complex structure, unreasonable overall design, and insufficient automation of venous needle assembly machines, so as to avoid blockage, save costs, Guarantee the effect of adding glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

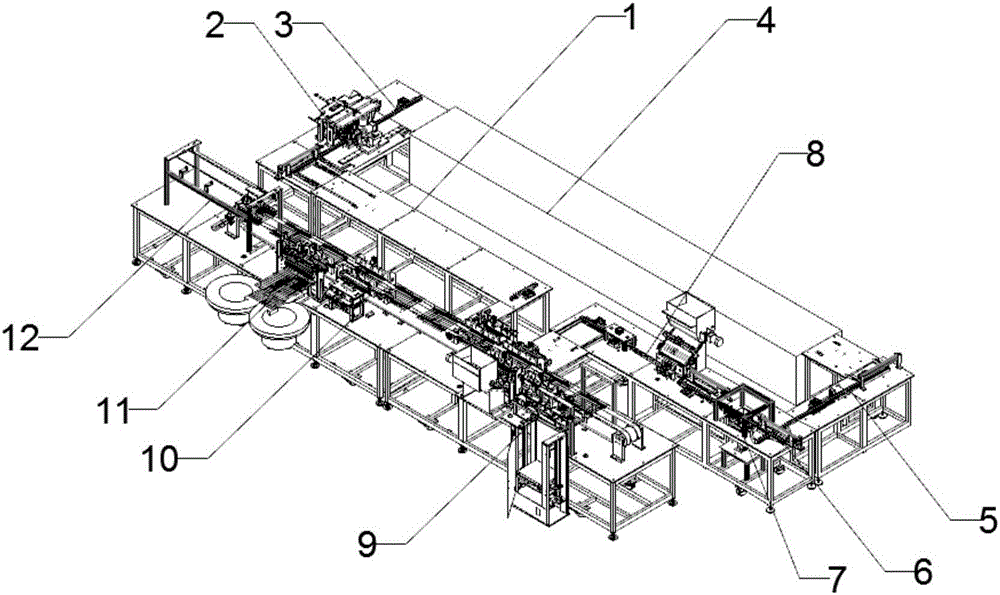

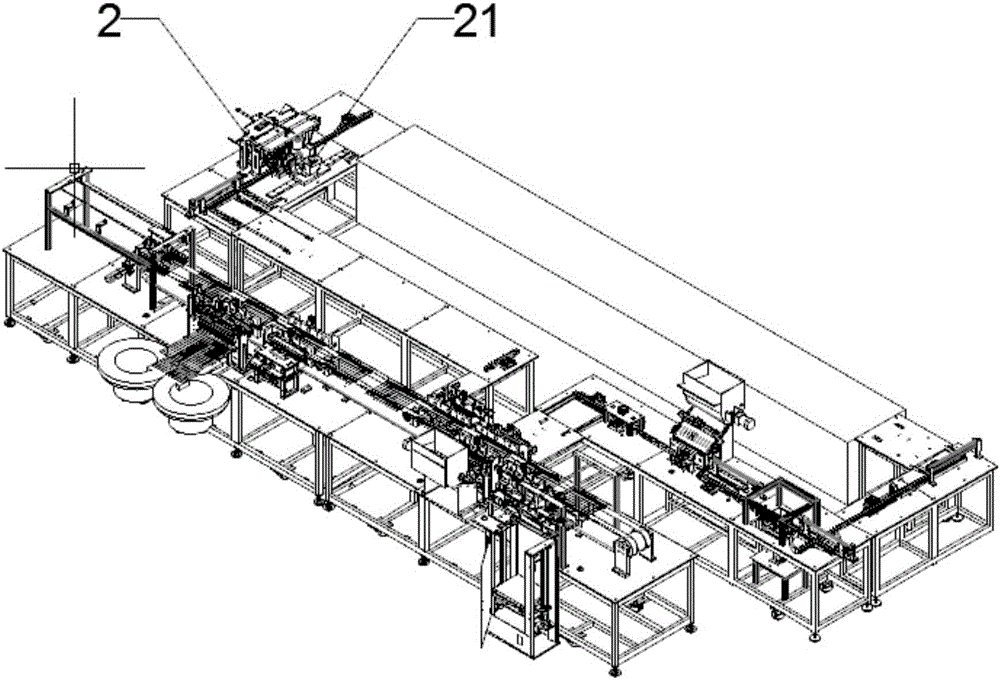

[0048] see figure 1 As shown, a double-wing venous needle catheter assembly machine includes a wing placement platform 1 for placing wings into the carrier 13, starting from the wing placement platform 1, and the rear conveyor belt of the wing placement platform 1 is connected to the upper The needle assembly 2, the conveyor belt behind the upper needle assembly 2 is connected to the right-angle transmission assembly 3, the conveyor belt behind the right-angle transmission assembly 3 is connected to the oven 4, the conveyor belt behind the oven 4 is connected to the reverse needle detection assembly 5, and the rear needle detection assembly 5 is connected to the conveyor belt. With a direction changing device 6, a first gas test device 7 is arranged behind the vehicle direction changing device 6, a sheath assembly 8 is connected to the conveyor belt behind the first gas test device 7, and a hose assembly assembly 9 is connected to the conveyor belt behind the sheath assembly 8 ...

Embodiment 2

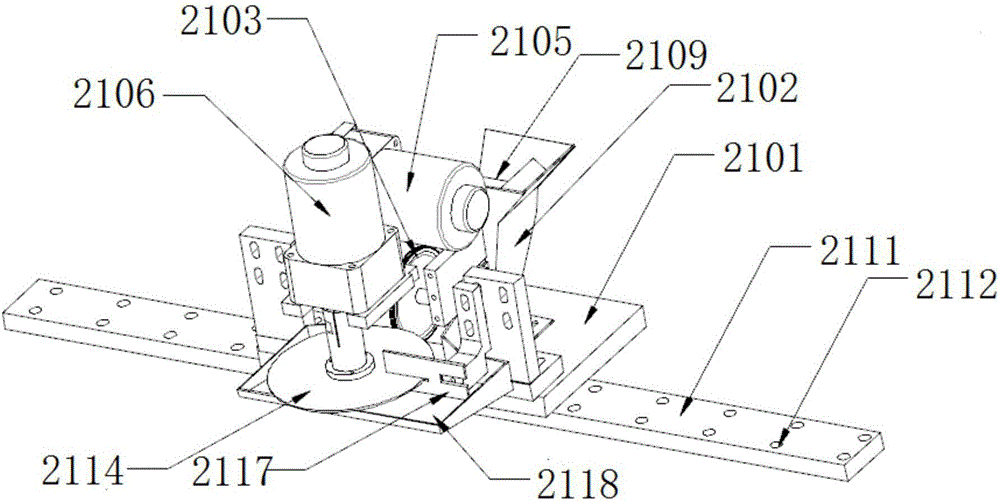

[0050] On the basis of embodiment 1, see figure 2 , image 3 Shown is a schematic structural view of the needle assembly 2 of this embodiment, including a needle point glue adding device 21, which includes a base 2101, above which is provided a glue tray 2102 for placing glue; also includes a glue adding wheel 2103 , the rubber adding wheel 2103 is set vertically, and the bottom extends into the glue tray 2102; it also includes a rubber upper wheel 2104, the upper rubber wheel 2104 is arranged horizontally, the rubber adding wheel 2103 is driven by the glue adding motor 2105, and the rubber upper wheel 2104 is driven by the glue applying motor Driven by 2106, the upper rubber wheel 2104 is also provided with a squeegee 2107 for scraping off overflowing glue. Below the squeegee 2107, an overflow plate 2108 is arranged, and the overflow plate 2108 communicates with the glue plate 2102. The glue plate 2102 is provided with The glue adding port 2109, the edge of the glue adding ...

Embodiment 3

[0052] On the basis of embodiment 1, see Figure 4 , Figure 5 Shown is a schematic structural view of the backstitch detection assembly 5 of this embodiment, including a backstitch detection device 51 and a picking device 52, the backstitch detection device 51 includes a base 511, a CCD camera 512 is arranged above the base 511, and a There is a carrier groove 513, and the carrier groove 513 is provided with a retaining device 514. The retaining device 514 includes a power cylinder 5141, and the power cylinder 5141 is connected with a retaining strip 5142. The base 511 is provided with a track groove 515, and the track groove 515 is Mobile platform 516 is provided, CCD camera 512 is provided with on mobile platform 516, and vertical cylinder 517 is also arranged on mobile platform 516, and vertical cylinder 517 is connected with push bar 518, and track groove 515 is provided with induction block 519, and track groove 515 An anchor point is set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com