Moving iron unit provided with E-shaped armature and receiver comprising moving iron unit

An armature and moving iron technology, applied in the field of receivers, can solve the problems of time-consuming and laborious, high difficulty in adjusting the positioning fixture, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further described in detail below in conjunction with specific embodiments:

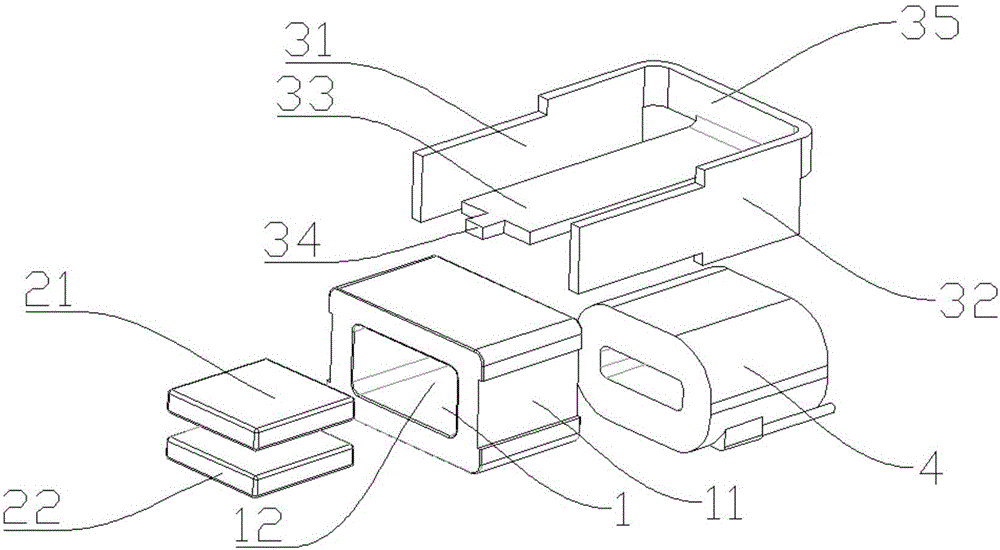

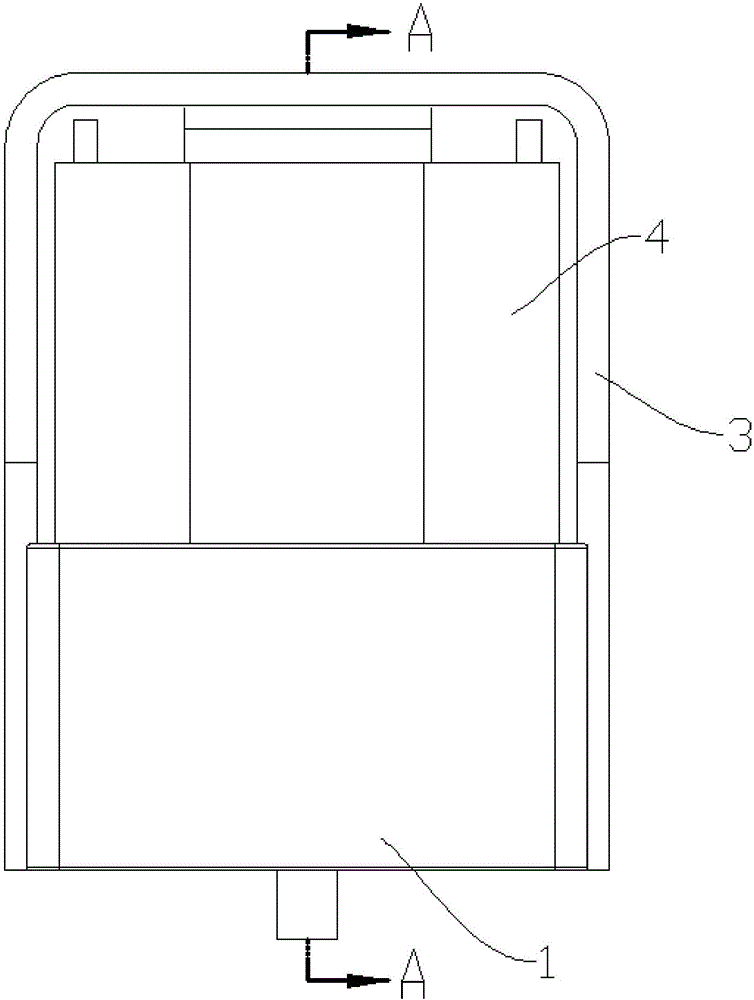

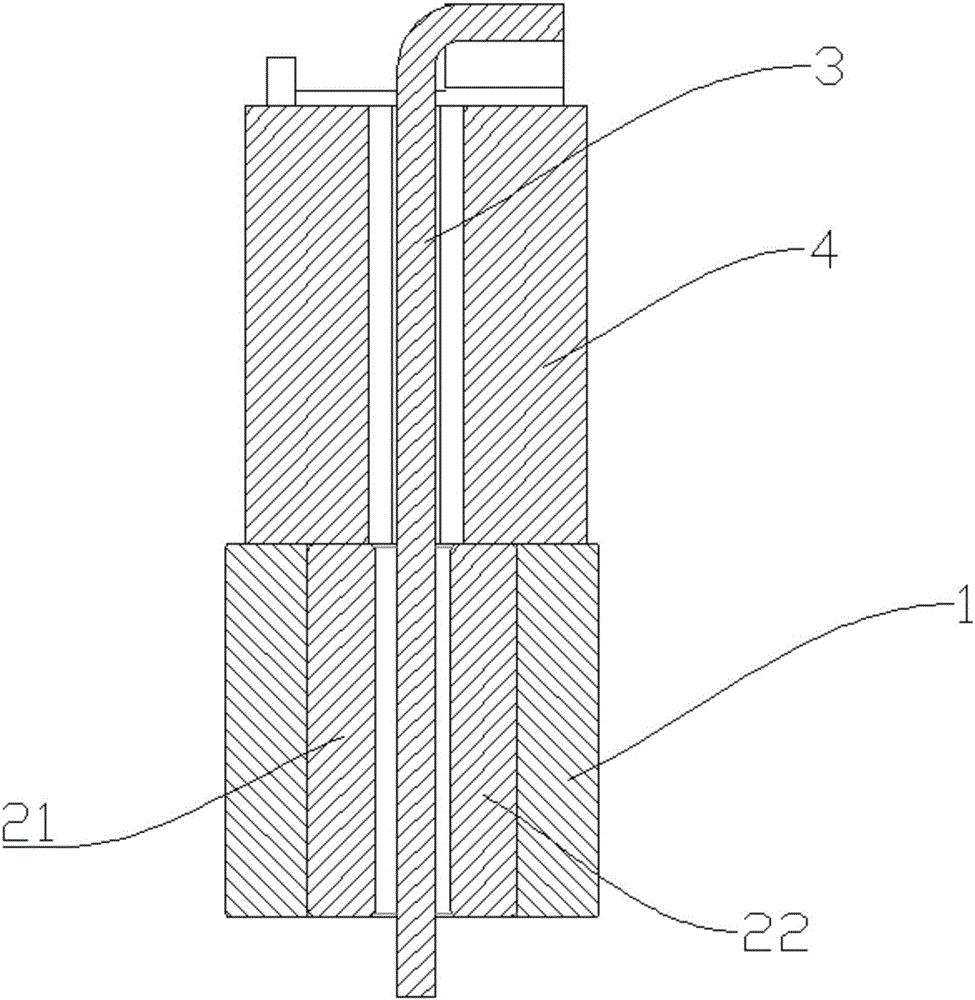

[0026] In order to achieve the purpose of the present invention, as shown in the figure, one embodiment of the present invention is: a moving iron unit with an E-shaped armature, including an iron core 1, a magnet 2, a coil 4, and an E-shaped armature 3. , The iron core 1 is provided with a mounting port 12 and at least two positioning slots 11, the magnet 2 is installed in the mounting port 12, the E-shaped armature 3 includes a first connecting portion 31, a second connecting portion 32, and a third connecting portion 33 And the turning portion 35, the first connecting portion 31, the second connecting portion 32 and the third connecting portion 33 are respectively connected with the turning portion 35 to form an "E" type structure, the first connecting portion 31, the second connecting portion 32 and the positioning groove 11, the third connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com