PVC electrical tube

A technology of electrical pipes and pipe bodies, which is applied in the field of pipelines, can solve the problems of large occupied space and high cost, and achieve the effects of ensuring construction, strengthening internal flame retardancy, and ensuring simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

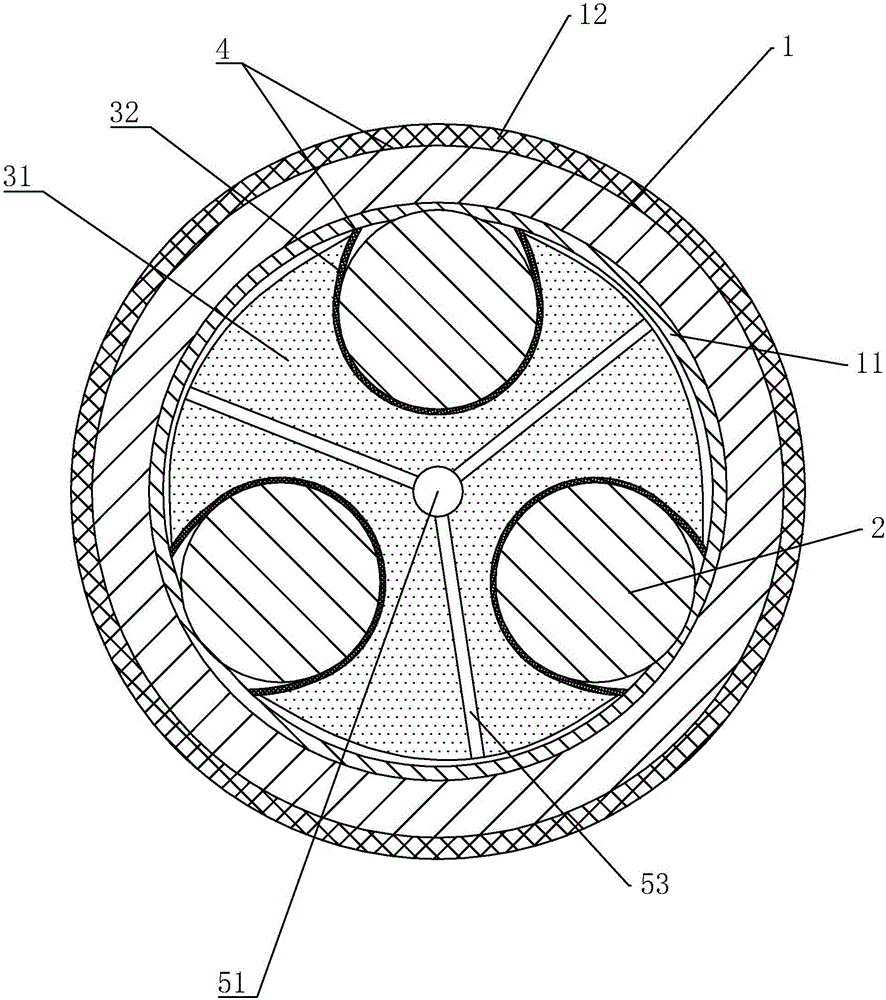

[0032] A PVC electrical pipe includes a pipe body 1 made of PVC material, the pipe body 1 is installed inside or outside a wall, and the cross section of the entire pipe body 1 presents a circular structure. The tube body 1 is provided with a plurality of inner tubes 2 for accommodating power lines or signal lines, and each inner tube 2 contains a kind of electric wire, or is a power line, or is a signal line, and the inner tube 2 can be made of an ordinary Plastic covered wire, which can be made of PVC material, binds the wires inside. There may be about three or four inner tubes 2 on each tube body 1 , and the number of inner tubes 2 is determined according to the inner diameters of the inner tubes 2 and the tube body 1 .

[0033] Such as figure 1 As shown, the tube body 1 is also provided with an elastic air bag 31 for fixing the inner tube 2 on the inner wall of the tube body 1, and the contact parts between the elastic air bag 31 and the inner tube 2 are all made of hard...

Embodiment 2

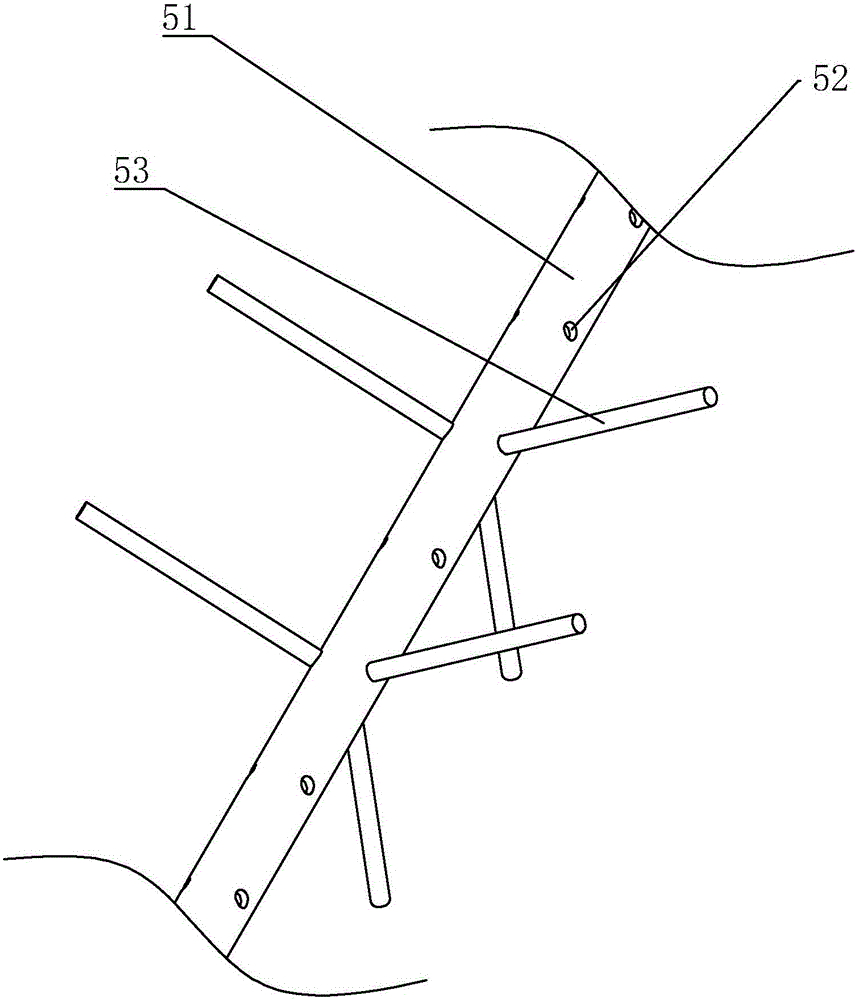

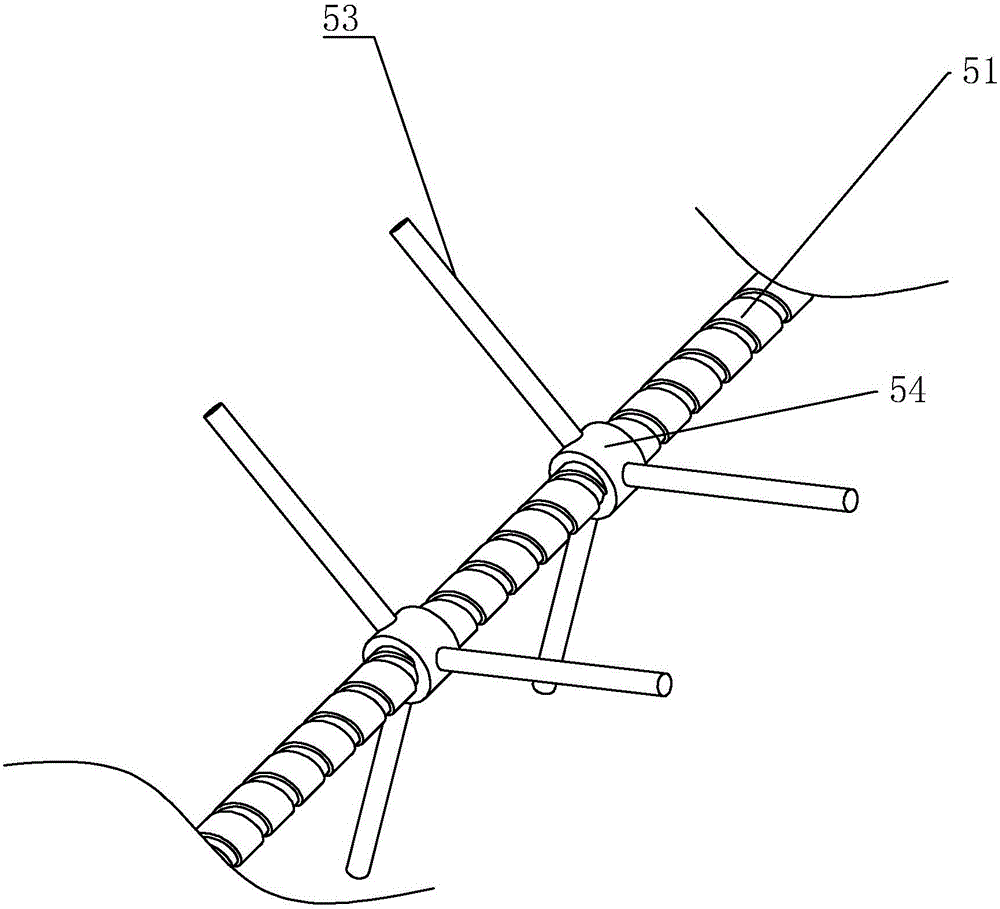

[0045] Such as image 3 As shown, a PVC electrical pipe, compared with Embodiment 1, the difference of Embodiment 2 lies in the structure of the cage, the outer surface of the central shaft 51 is provided with threads, and the outer surface of the central shaft 51 is provided with a A threaded shaft sleeve 54, a plurality of support rods 53 are distributed on the circumference of the shaft sleeve 54, and the rotation of the shaft sleeve 54 can be adjusted axially by rotating the shaft sleeve 54 to ensure that the support rods 53 on the shaft sleeve 54 able to move to a suitable location. When processing to produce the cage, the shaft sleeve 54 and the support rod 53 can be processed separately, and then the support rod 53 is welded on the shaft sleeve 54, and the support rod 53 of the same specification is welded on each shaft sleeve 54. The number of support rods 53 can be increased or decreased according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com