Constant current control system for continuous current mode (CCM) and discontinuous conduct mode (DCM) of primary-side feedback flyback power supply

A technology of primary side feedback and constant current control, applied in the direction of control/regulation system, regulation of electrical variables, instruments, etc., can solve the problem of high implementation cost, achieve the effect of reducing development cost, easy implementation, and simple control implementation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

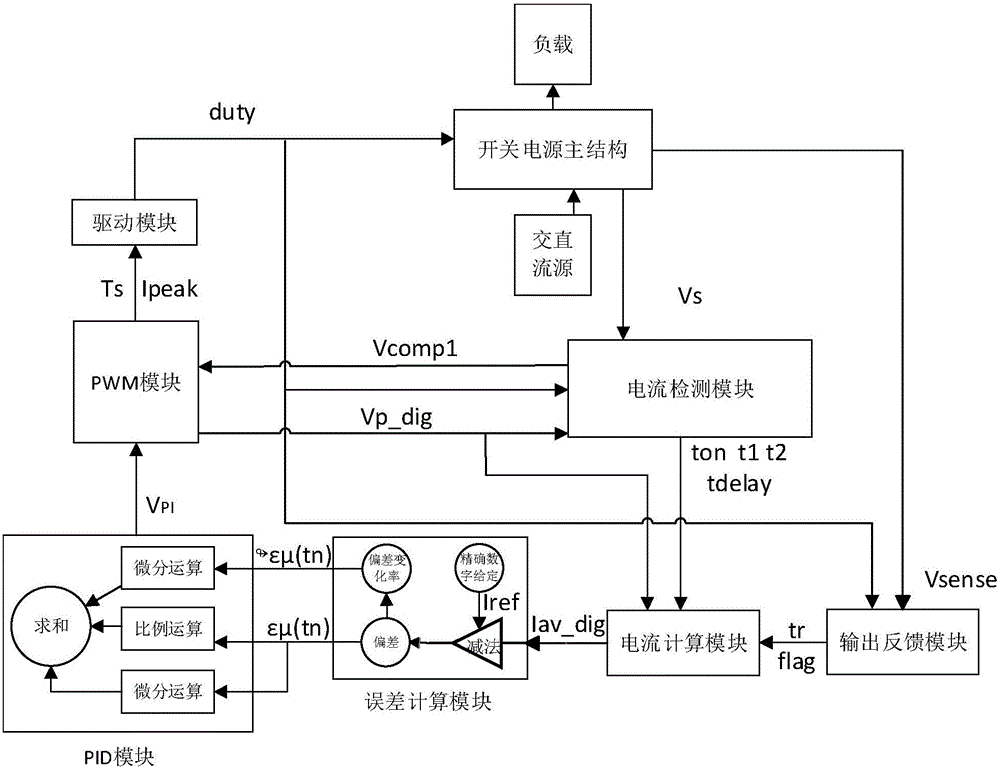

[0026] The control system for improving the constant current precision of switching power supply in the present invention is as follows: Figure 1a and Figure 4 , based on a control system consisting of a current detection module, an output feedback module, a current calculation module, an error calculation module, a PID module, a PWM module, and a drive module. The control system is connected with a controlled switching power supply to form a closed loop. The current detection module , the output feedback module collects the basic parameters to realize the constant current algorithm, the current calculation module calculates the average current of the primary inductor during the switch on stage, and calculates the average current of the secondary output current according to the turn ratio relationship between the input and output, and through the The current is time-integrated and averaged to obtain the output current, and the output value is executed in the digital PID modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com