Sludge sufficient combustion processing device

A technology of full combustion and treatment equipment, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of complex equipment, large investment, low incineration efficiency, etc., to reduce energy consumption, improve treatment effect, and good preheating effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

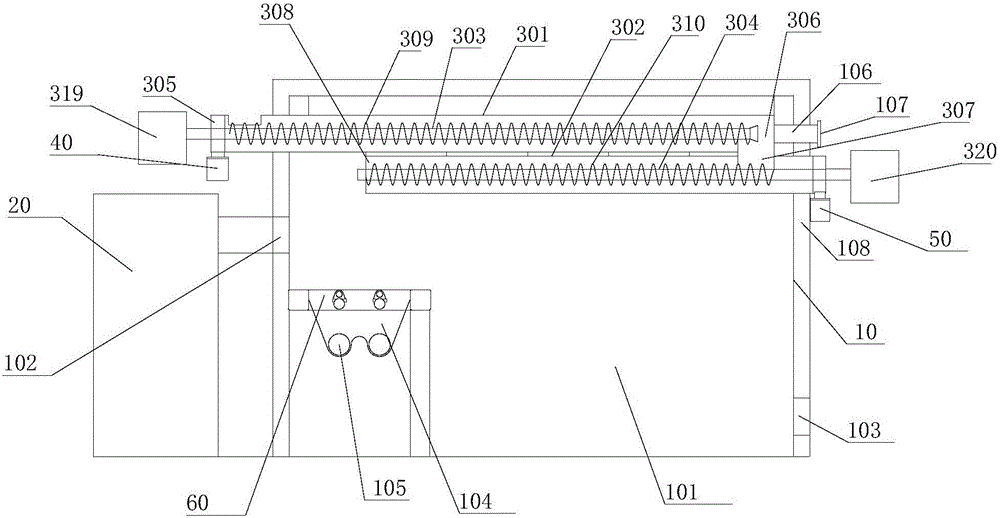

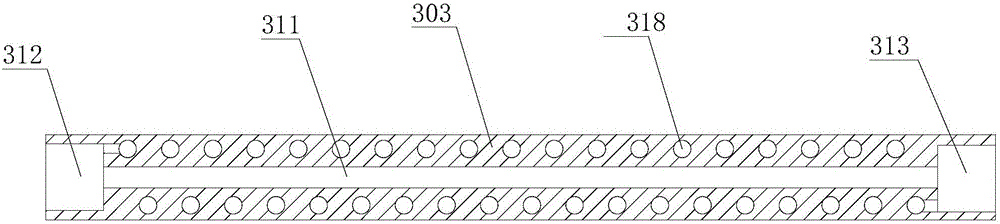

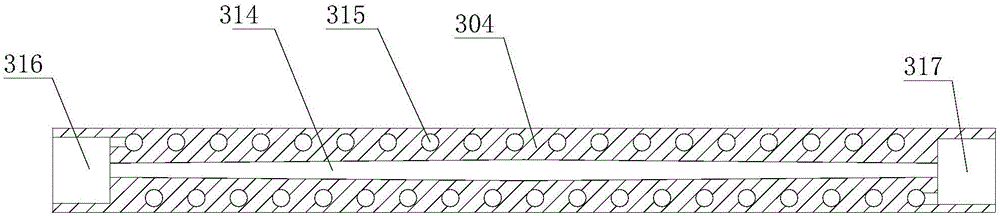

[0022] refer to figure 1 , figure 2 , image 3 , the present invention proposes a sludge full combustion treatment device, including a furnace body 10, a hot air generating mechanism 20 for sending hot air into the furnace body 10, a feeding mechanism for conveying sludge into the furnace body 10, a second An air extraction mechanism 40, a second air extraction mechanism 50, and a fire grate 60. The feeding mechanism includes a first housing 301, a second housing 302, a first rotating shaft 303, a second rotating shaft 304, a first driving mechanism 319 and a second Two driving mechanisms 320, wherein:

[0023] The furnace body 10 has a combustion chamber 101 . The furnace body 10 is provided with an air inlet 102 and an air outlet 103 communicating with the combustion chamber 101 . The outer side of the furnace body 10 is covered with an insulating layer 108 .

[0024] The hot air generating mechanism 20 communicates with the air inlet 102 of the furnace body 10 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com