A multi-stage stacked variable-diameter split-flow anti-reflash tank device

A backfire prevention and tank technology, applied in fire rescue, gas/liquid distribution and storage, pipeline system, etc., can solve the problem of large gas backfire and achieve the effect of preventing backfire phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

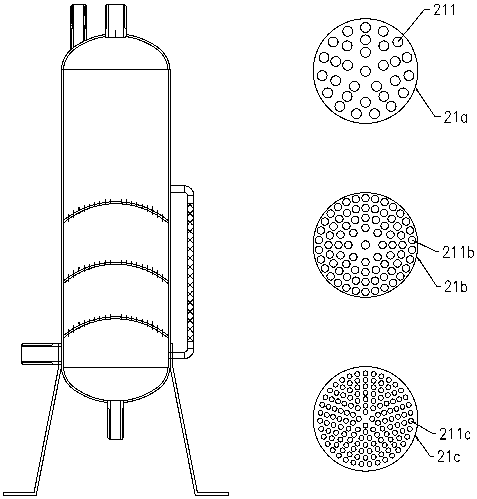

[0014] refer to figure 1 with figure 2 , a multi-stage stacked variable-diameter diversion anti-reflash tank device, including two tanks 2 and a check valve 5 arranged between the two tanks 2, the front end adjacent to the gas source 1 is used adjacent to the gas The end 4 is the rear end, and the inside of the tank body 2 is provided with a first partition 21a, a second partition 21b and a third partition 21c at intervals from bottom to top, and the first partition 21a is provided with 139 first partitions. Through holes 211a, the second partition 21b is provided with 62 second through holes 211b, and the third partition 21c is provided with 36 third through holes 211c, the diameter of the third through holes 211c is the largest, and the second through holes 211b is next, the aperture of the first through hole 211a is the smallest, the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com