Inflatable adjustable type construction mold for reserved hole in concrete structure plate, and construction method

A technology of concrete structure and reserved holes, which is applied in the fields of formwork/formwork/work frame, building structure, and on-site preparation of building components, etc. The effect of firm and reliable fixation, accurate mold positioning and accurate relative coordinates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

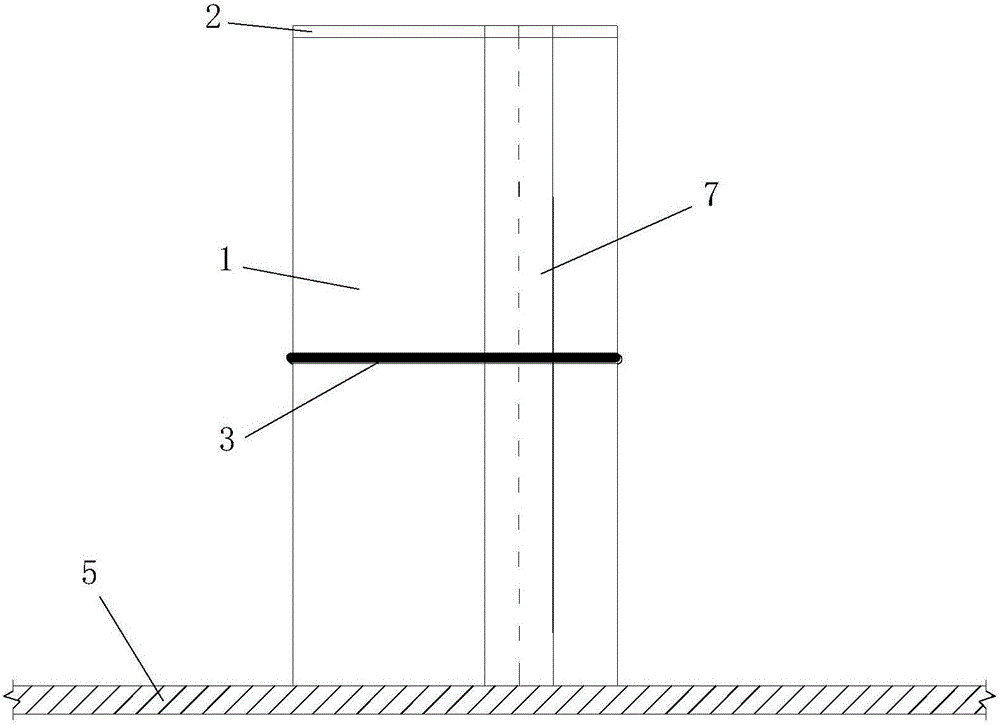

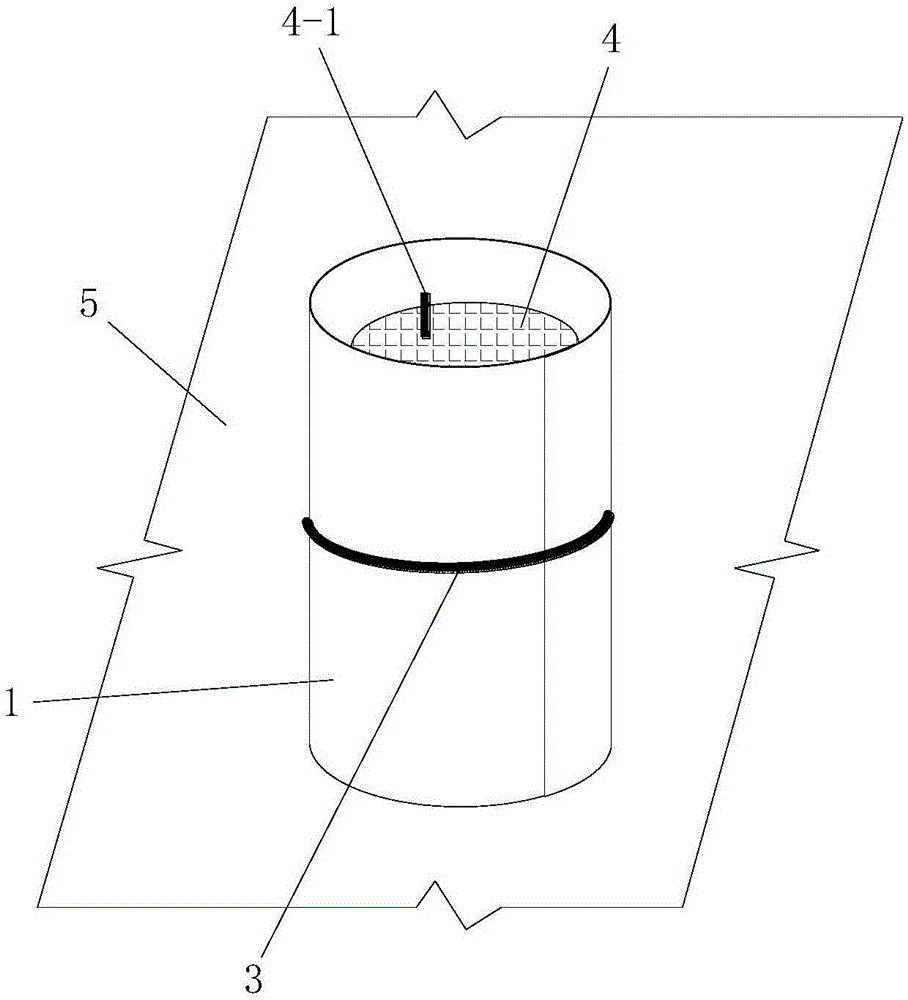

[0066] Such as figure 1 , figure 2 and image 3 An inflatable adjustable concrete structure board pre-hole construction mold shown includes a cylinder 1 rolled from a rectangular iron sheet, a circular cover plate 2 for blocking the upper port of the cylinder 1, and a circular cover plate 2 placed on the cylinder 1. Inside the inflatable airbag 4, the cylinder 1 is arranged vertically, the circular cover plate 2 is arranged horizontally and its diameter is not less than the outer diameter of the cylinder 1; the outer diameter of the cylinder 1 is consistent with the concrete structure The hole diameters of the holes to be constructed in the board are the same, the length of the rectangular iron sheet is L=πD+d, where D is the hole diameter of the holes to be constructed, d=180mm~220mm; the width W of the rectangular iron sheet is larger than the inflatable The height of the airbag 4, the height of the inflatable airbag 4 is not less than the thickness of the concrete structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com