A system and method for laying lever type ground piles

A lever type, ground pile technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of easy smashing of hands and feet, time-consuming and labor-intensive, low efficiency, etc., saving time, convenient line connection, contact good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

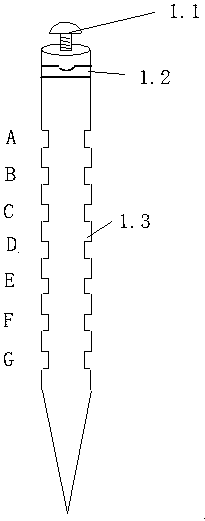

[0021] Such as Figure 1 to Figure 6 As shown, a lever-type ground pile deployment system includes a ground pile 1, a ground pile sleeve 2, a lever 3, and a bracket 4. The ground pile sleeve 2 is sleeved with a ground pile 1, and the upper part of the ground pile sleeve 2 The outer part is hingedly connected to the short arm end of the lever 3, and the lever 3 is hingedly connected to the bracket 4 through a detachable pin 6.

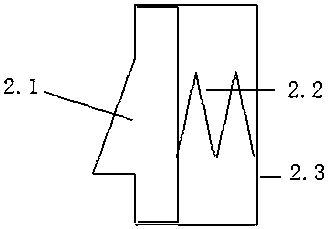

[0022] The pile sleeve 2 is a one-way moving pile sleeve. The inner wall of the pile sleeve 2 is provided with two pairs of retractable tongue-shaped latches 2.1, each pair of retractable latch-shaped latches 2.1 is provided at the rear end There is a spring 2.2, the spring 2.2 is provided with a detachable protective cover 2.3 fixed by screws, and the back plate of the detachable protective cover 2.3 is provided with an opening door for easy maintenance, and the diameter of the pile sleeve 2 is larger than the diameter of the pile 1.

[0023] The lever 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com