Deep hole and ultra-deep hole static cone penetration test method and apparatus

A technology of static penetration testing and testing equipment, which is applied in the field of foundation soil survey, construction, and basic structure engineering, etc. It can solve problems such as breaking, easy bending of the probe rod, and difficulty in penetrating the cone head through the casing, so as to reduce the Effects of probe deflection angle, increased test depth, and reduced side wall friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

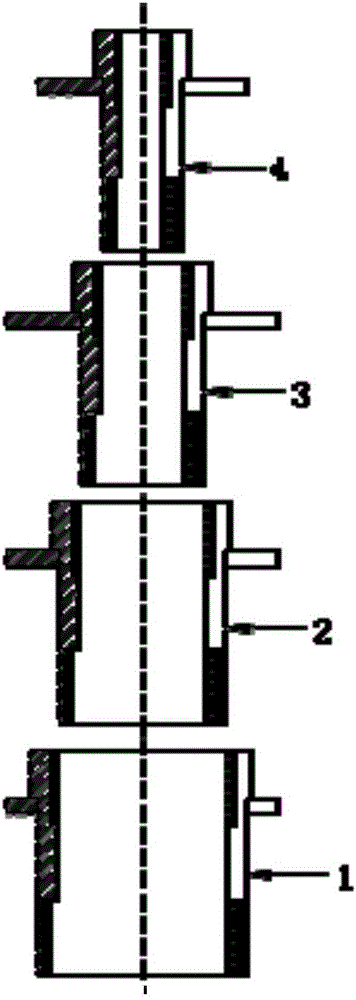

[0022] Referring to the accompanying drawings, the present invention will be described in detail by taking the five-fold casing as an example.

[0023] refer to figure 1 , 2 , 3. The deep hole and ultra-deep hole static penetration test equipment has 5 casings with diameters ranging from large to small. Except for the casing with the largest diameter, each casing has a matching casing joint. The 5 casing diameters They are 180mm casing (maximum diameter), 146mm casing, 127mm casing, 110mm casing, 63.5mm casing, and the matching casing joints are 146mm casing joint 1, 127mm casing joint 2, 110mm Casing joint 3, 63.5mm casing joint 4. The lower part of the φ63.5 casing is joined with a gold drill bit by a screw.

[0024] An annular tray 6 is arranged on each casing joint, and threaded buttons 5 are arranged in the upper and lower openings. The threaded buttons in the upper and lower mouths are square threaded buttons with a tooth width of 2mm.

[0025] The a, b, c, d, e, f,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com