Fixing device for water stop belt for water conservancy engineering and water stop belt installing method

A technology for water conservancy projects and fixtures, applied in water conservancy projects, marine engineering, construction, etc., can solve problems such as affecting the water-stop effect and the end of the water-stop belt, so as to increase the water-stop effect, prevent displacement, and ensure safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

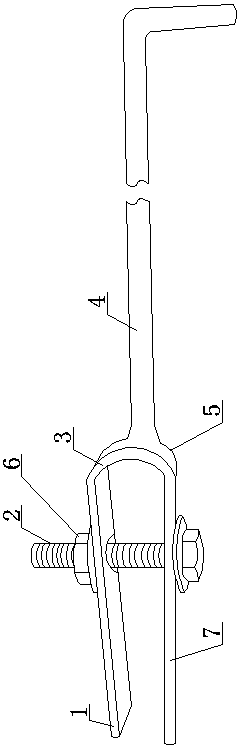

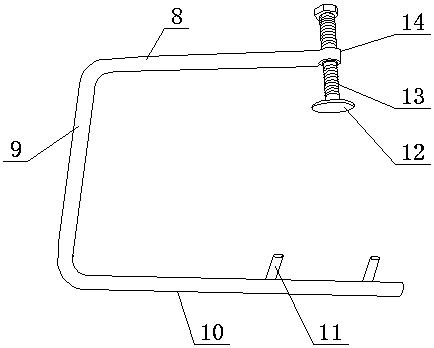

[0046] as attached figure 1 And attached figure 2 As shown, the waterstop fixing device for water conservancy projects of the present invention includes a positioning bracket 5 for fixing the waterstop 17 in the concrete and a fixing bracket 14 for fixing the waterstop 17 outside the concrete, and the positioning bracket 5 includes a splint, an adjustment mechanism and a tension rod 4. The splint is a 匚-shaped splint mainly composed of two horizontal plates and a vertical plate 3. The adjustment mechanism is arranged on the splint and can adjust the opening diameter of the splint. The tension rod 4 One end of the vertical plate is fixed vertically on the outer surface of the riser 3, and the other end of the lacing bar 4 is bent to be L-shaped; The vertical bar 9 forms the U-shaped pressure bar, and the fixing bolt 13 vertically runs through any cross bar.

[0047] Among them, the two horizontal plates are the upper horizontal plate 1 and the lower horizontal plate 7 respecti...

Embodiment 2

[0054] In the waterstop installation method for water conservancy projects of the present invention, the waterstop 17 is fixed between the first-stage concrete and the second-stage concrete through the waterstop fixing device for water conservancy projects in Embodiment 1, and the steps are as follows:

[0055] (1) Build the first phase of structural reinforcement;

[0056] (2) On the waterstop 17, the inner side of the side waterstop 17 for pouring the first-stage concrete, the inner side of the waterstop 17 holds a plurality of positioning brackets 5 arranged at intervals, and the above multiple positioning The brackets 5 are arranged along the axial direction of the waterstop 17, and the inner part of the waterstop 17 is fixed on the first-stage structural reinforcement through the above-mentioned multiple positioning brackets 5;

[0057] (3), laying the formwork 16, the first-stage structural reinforcement, the inner side of the waterstop 17 and the above-mentioned multipl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com