A kind of modified cyanate ester resin and preparation method thereof

A cyanate ester resin and a modification technology are applied in the field of modified cyanate ester resin and its preparation, which can solve the adverse effects of heat resistance and dielectric properties, cannot take into account the catalytic and toughening properties, and destroy the triazine ring structure. and other problems, to achieve the effect of high toughness, good curing processability and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present embodiment provides a kind of preparation of modified cyanate ester curing resin, and concrete steps are as follows:

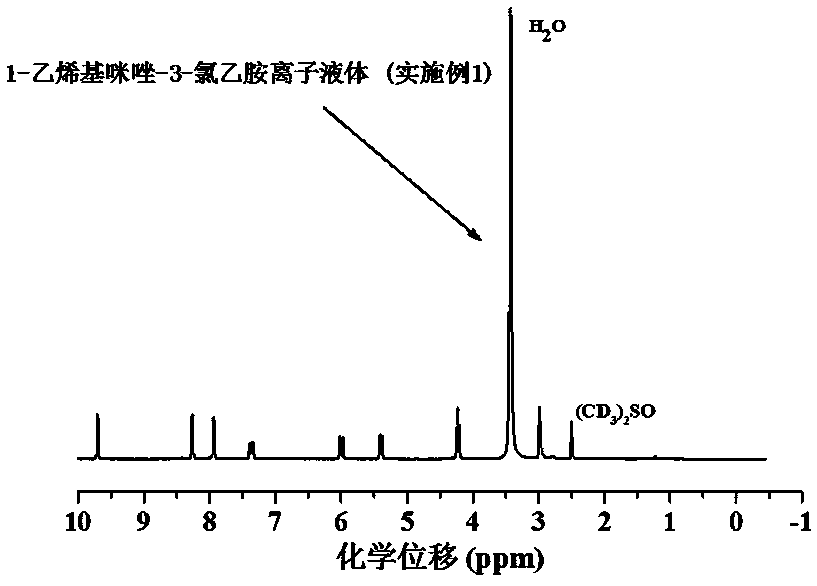

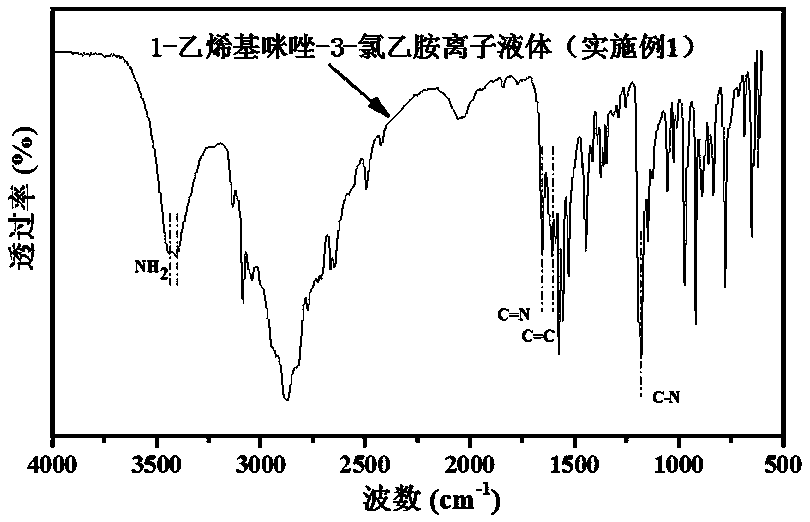

[0046] (1) Preparation of 1-vinyl N-heterocyclic-3-chloroethylamine ionic liquid containing amino-terminated

[0047] In nitrogen (N 2 ) protection, 9.4 g of N-vinylimidazole was added dropwise to 11.3 g of 2-chloroethylamine hydrochloride, and the reaction was refluxed at a temperature of 70 ° C for 24 h. After the reaction was finished, it was repeatedly washed with ethanol three times, and dried in vacuum at 25° C. for 4 hours to obtain amino-terminated ionic liquid hydrochloride A.

[0048] Add 10.5g of amino-terminated ionic liquid hydrochloride A to 21mL of water to dissolve to obtain an aqueous solution of amino-terminated ionic liquid hydrochloride A; slowly add 2.1g of NaOH to the aqueous solution of amino-terminated ionic liquid hydrochloride A, at 20°C The reaction was stirred for 5h. Then freeze-dry to remove solvent water; di...

Embodiment 2

[0065] (1) Preparation of polyionic liquid modified carbon nanotube hybrid material / cyanate resin prepolymer

[0066] 0.5g of the polyionic liquid modified carbon nanotube hybrid material prepared in step (3) of Example 1 and 49.5g of 2,2'-bis(4-cyanophenyl)propane (also known as bisphenol A cyanate ) into a beaker, stirred at 110°C and ultrasonicated for 30 minutes; then prepolymerized and stirred at 140°C for 10 minutes to obtain a polyionic liquid modified carbon nanotube hybrid material / cyanate resin prepolymer, in which the polyionic liquid modified The content of the carbon nanotube hybrid material is 1wt%. The differential scanning calorimetry (DSC) curve of this modified cyanate resin prepolymer is shown in the appendix Figure 7 .

[0067] (2) Preparation of modified cyanate ester cured resin

[0068] Pour the polyionic liquid-modified carbon nanotube hybrid material / cyanate resin prepolymer prepared above into the mold, and degas the bubbles under vacuum at 140°C ...

Embodiment 3

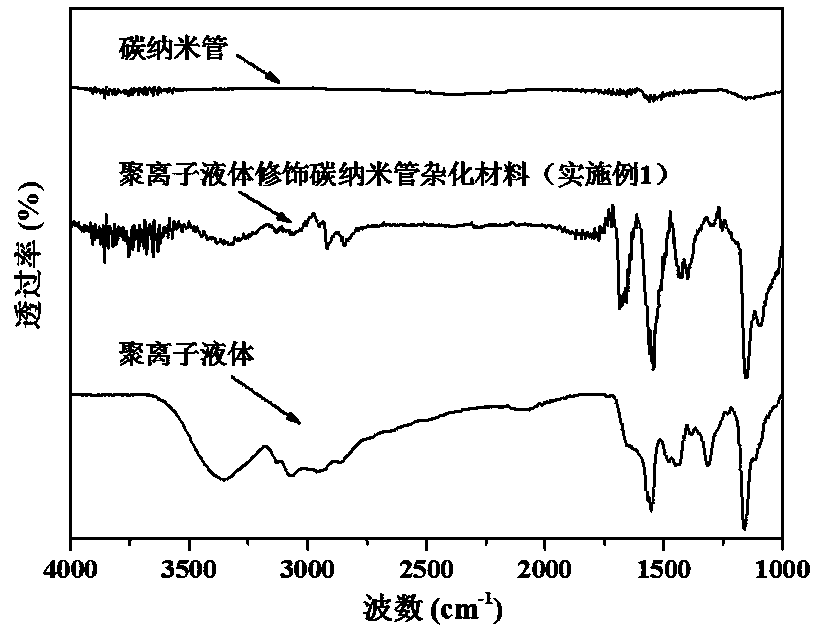

[0081] (1) Preparation of polyionic liquid modified carbon nanotube hybrid materials

[0082] Add 5 g of the ionic liquid D containing amino-terminated and transition metals prepared in step (2) of Example 1 into 100 mL of deionized water and fully dissolve to obtain a clear and transparent solution E. Add 2g of single-walled carbon nanotubes to the E solution, and ultrasonically disperse for 30min to obtain a uniformly dispersed single-walled carbon nanotube dispersion F; then add 10mL of azobisisobutyronitrile Methanol solution (15mg / mL), reflux at 60°C for 24h. After the reaction, it was suction filtered, washed with deionized water, and freeze-dried for 48 hours to obtain a polyionic liquid-modified carbon nanotube hybrid material.

[0083] (2) Preparation of modified cyanate ester cured resin

[0084] Add 0.5g of the polyionic liquid-modified carbon nanotube hybrid material in the above step and 49.5g of 4,4'-dicyanate-diphenylethane (bisphenol E-type cyanate) into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com