Modular molecular sieve oxygenerator

A molecular sieve oxygen generator and molecular sieve technology, applied in the field of oxygen generators, can solve the problems of high production and installation costs, production and installation costs, and large equipment footprint, so as to reduce transformation, reduce maintenance time, and occupy an area small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

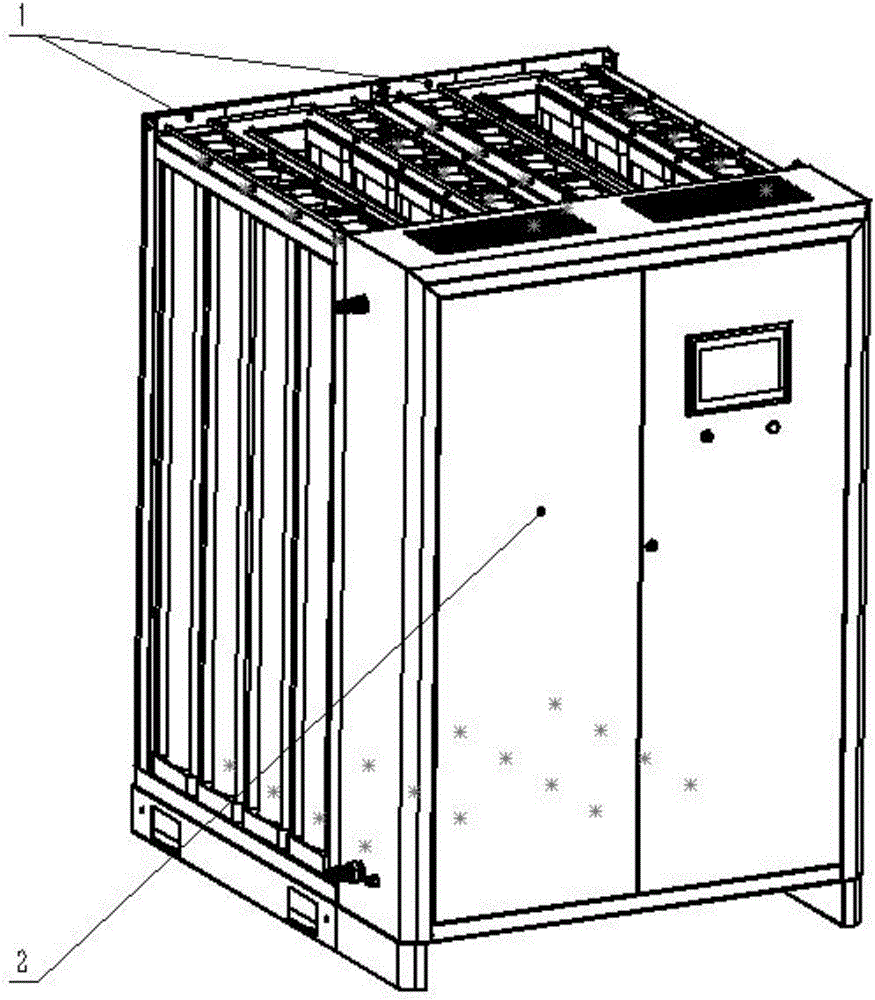

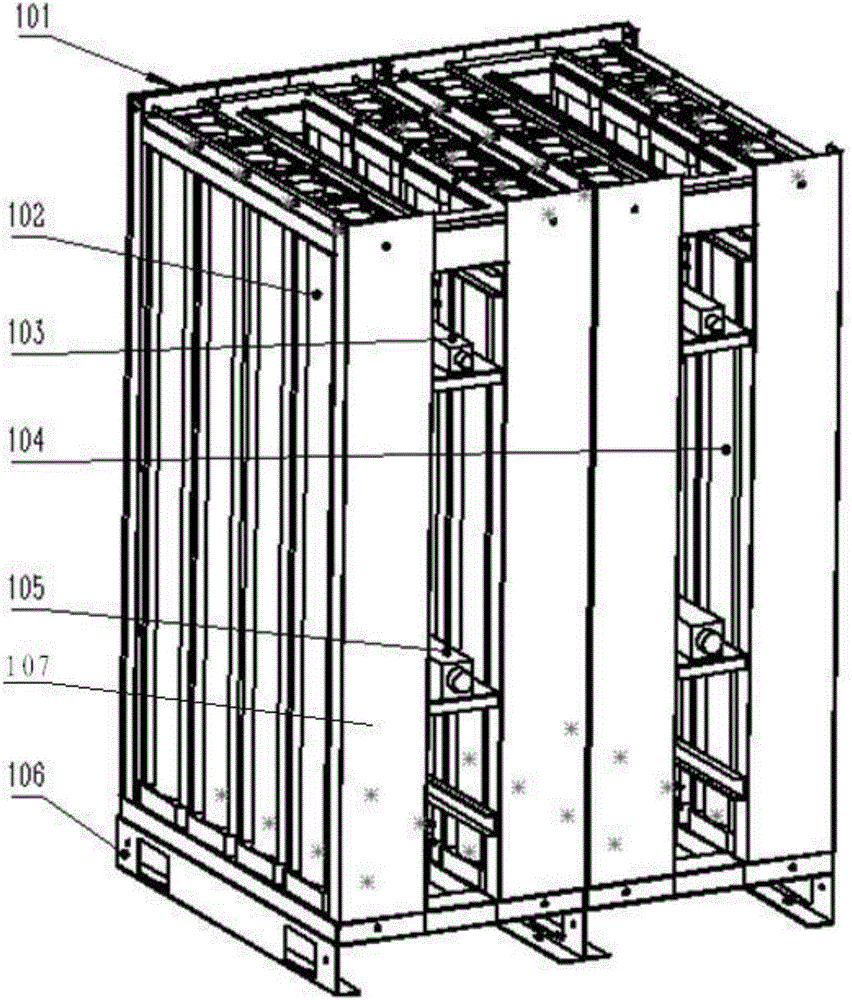

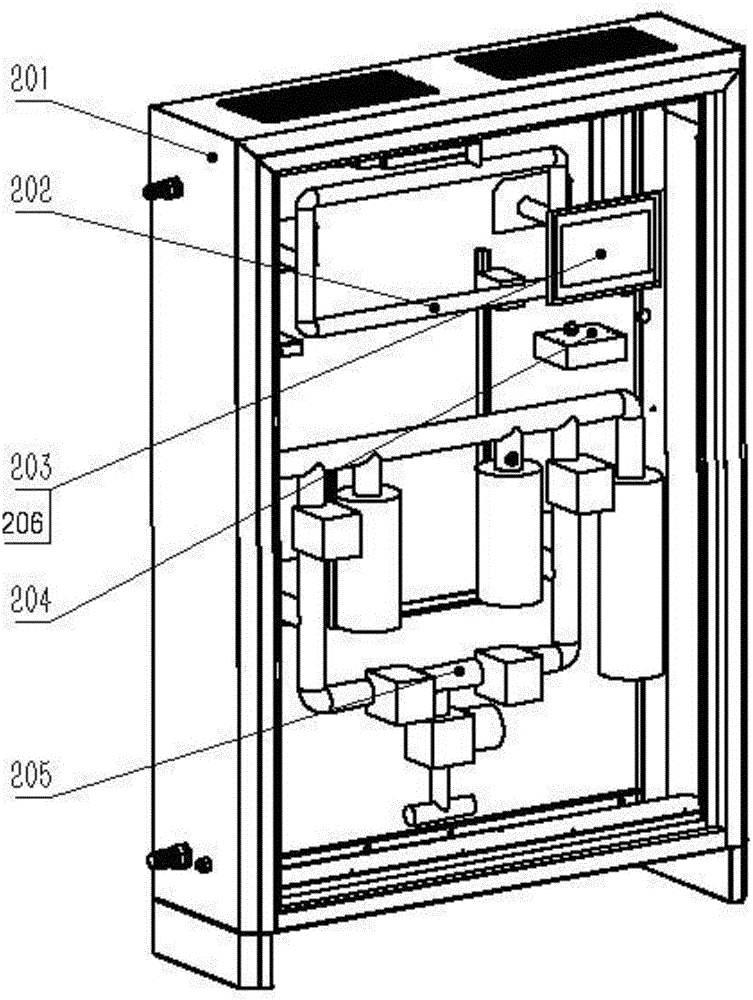

[0016] As shown in the accompanying drawings, a modular molecular sieve oxygen generator includes at least one molecular sieve tower module 1 and a control and input-output module 2. In this embodiment, two molecular sieve tower modules are included: Group A molecular sieve tower module 102 and group B molecular sieve column module 104 . Each described molecular sieve tower module 1 comprises bottom shell 106, top shell (not shown in the figure, it is positioned at the top of molecular sieve tower module), back shell 101, two groups of molecular sieve towers, air pipeline 105, oxygen pipeline 103, Each group of molecular sieve towers includes at least one molecular sieve tower. The number of molecular sieve towers of the two groups of molecular sieve towers is the same. 105 runs through and is arranged between two groups of molecular sieve towers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com