Withdrawing type coiling module

A pull-out and coiling technology, applied in the field of pull-out coiling modules, can solve the problems of unsmooth retraction and pull-out of the wire, large thickness, etc., and achieve the advantages of stretching and recycling, low resistance, and smooth rolling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

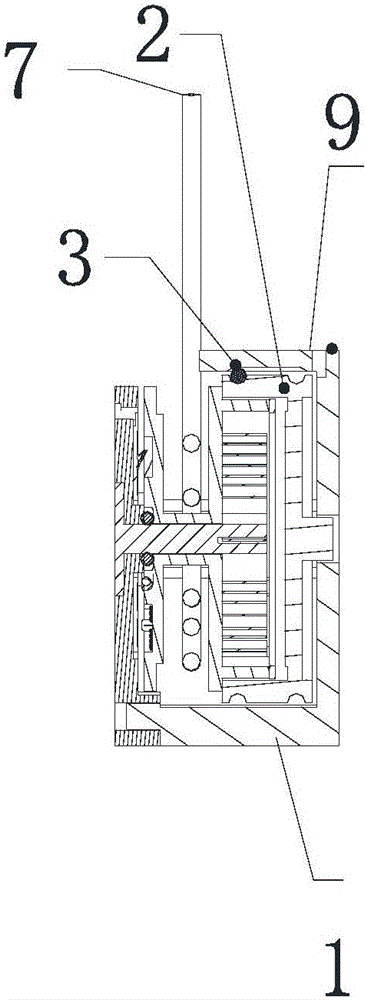

[0034] Such as Figure 1 to Figure 3 As shown together, the embodiment of the present invention provides a pull-type wire winding module, which is provided with a rotating wheel 6, which can rotate around the rotating shaft 8, the rotating wheel 6 is connected with a coil spring 5, and the wire 7 is wound on the rotating wheel 6 On the top, a stop mechanism is provided in cooperation with the runner 6, the stop mechanism includes a functional track, a ball 3 and a rolling auxiliary device, the functional track includes a locking track connected to the combination, a communication track 25 and a circular track (21, 22), three All these tracks are grooved and arranged around the outer circumference of the runner 6 (the track needs to be set by means of the cover 2), and balls 3 are arranged in the functional track. In the embodiment of the present invention, the track is arranged around the outer circumference of the runner 6. Compared with the track being arranged on the end fa...

Embodiment 2

[0054] The difference between the second embodiment of the present invention and the first embodiment is that the runner 6 is sheathed with a track wheel, and three kinds of tracks are arranged on the outer circumference of the track wheel, and the track wheel and the runner 6 are clipped together, and can Rotate together with runner 6.

[0055] The rest of the structure of Embodiment 2 of the present invention is similar to that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the three kinds of tracks are directly arranged on the outer circumferential surface of the runner 6, and there is no need to use other components to set the tracks, but the number of runners 6 should be appropriately increased. radial thickness, and to avoid conflict between the track and the cover structure of the coil spring placement slot. This design can further reduce the radial dimension of the winding module.

[0058] The rest of the structure of this embodiment is similar to that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com