Method for printing a printed image on an object

A technology for printing images and objects, applied in printing, copying/marking methods, typewriters, etc., to achieve the effect of fine positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

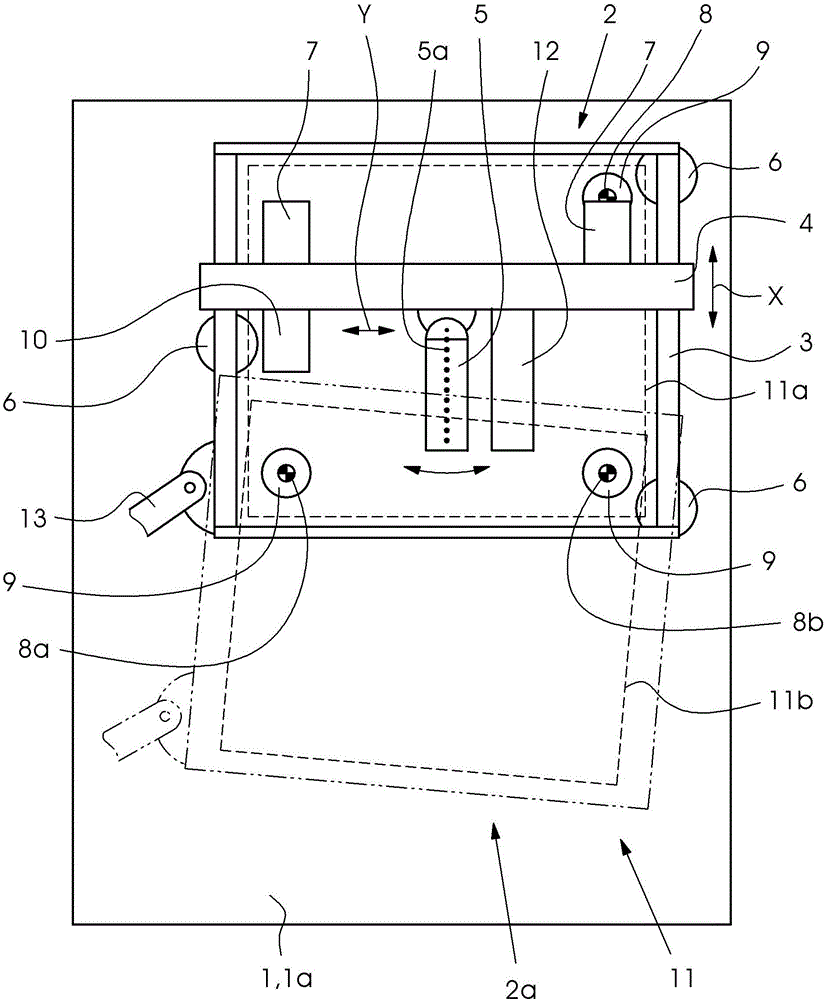

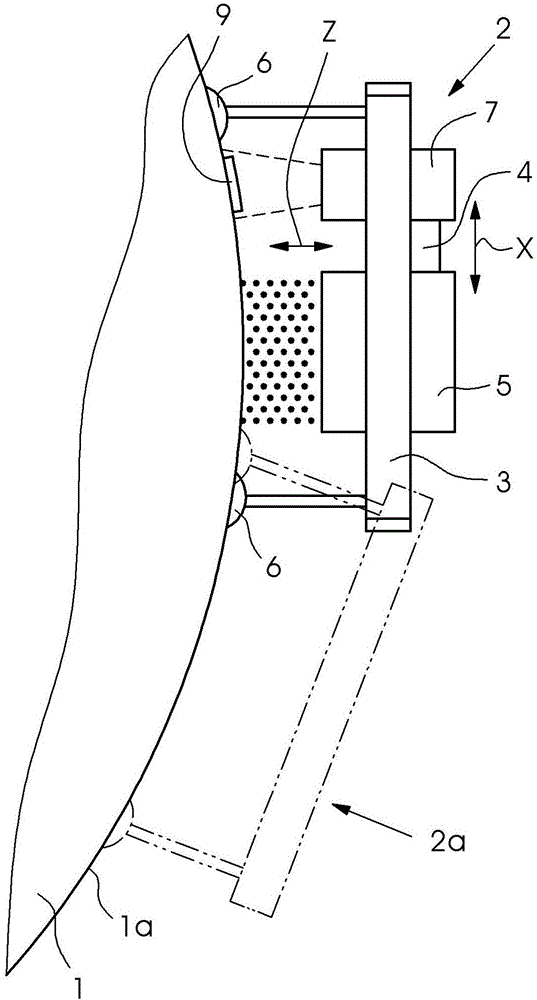

[0037] figure 1 A first view (from the Z direction) of a three-dimensional object 1 and a printing device 2 arranged on the three-dimensional object is shown while carrying out the method according to the invention. The object has a surface 1a that is not flat but curved. For example, a section of an aircraft fuselage may be involved.

[0038] The printing device 2 comprises a frame 3 and a crossbar 4 movable on the frame 3 in the X direction. The inkjet print heads 5 are arranged on this bar so as to be movable in the Y direction. The print head can also be oscillated in direction α (in the Z direction about an axis perpendicular to the X-Y plane) to orient the nozzle row 5a relative to the track to be printed during the printing movement (X and / or Y direction) (in particular oriented vertically), or to print tracks that do not extend parallel to the frame and / or the crossbar, or to be able to print in the edges.

[0039] The printing device is arranged with three suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com