A plastic bottle blowing machine mold installation platform

A technology for installing a platform and a blow molding machine, which can be used in household appliances, other household appliances, household components, etc., and can solve problems such as poor stability and inconvenience in movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

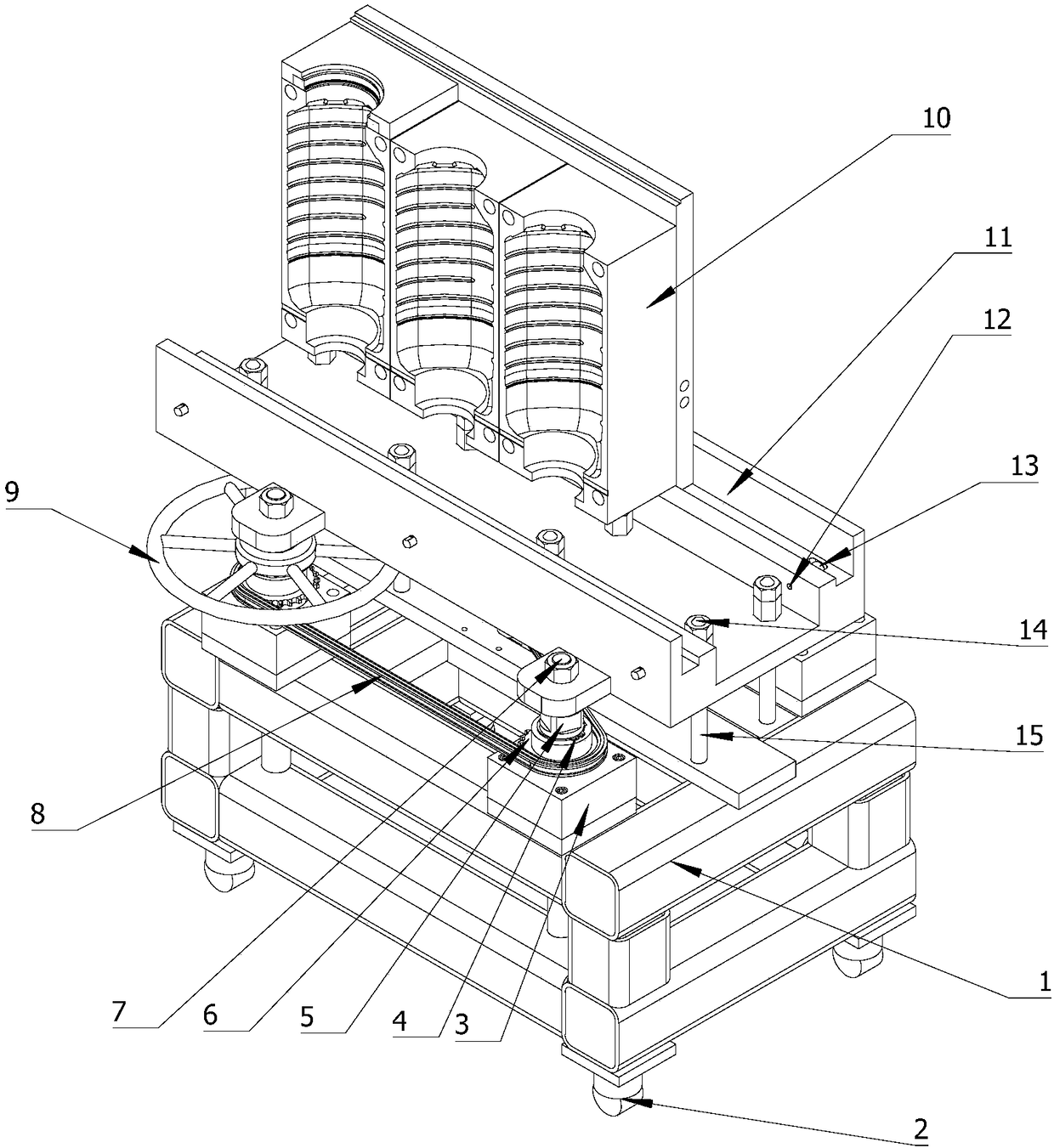

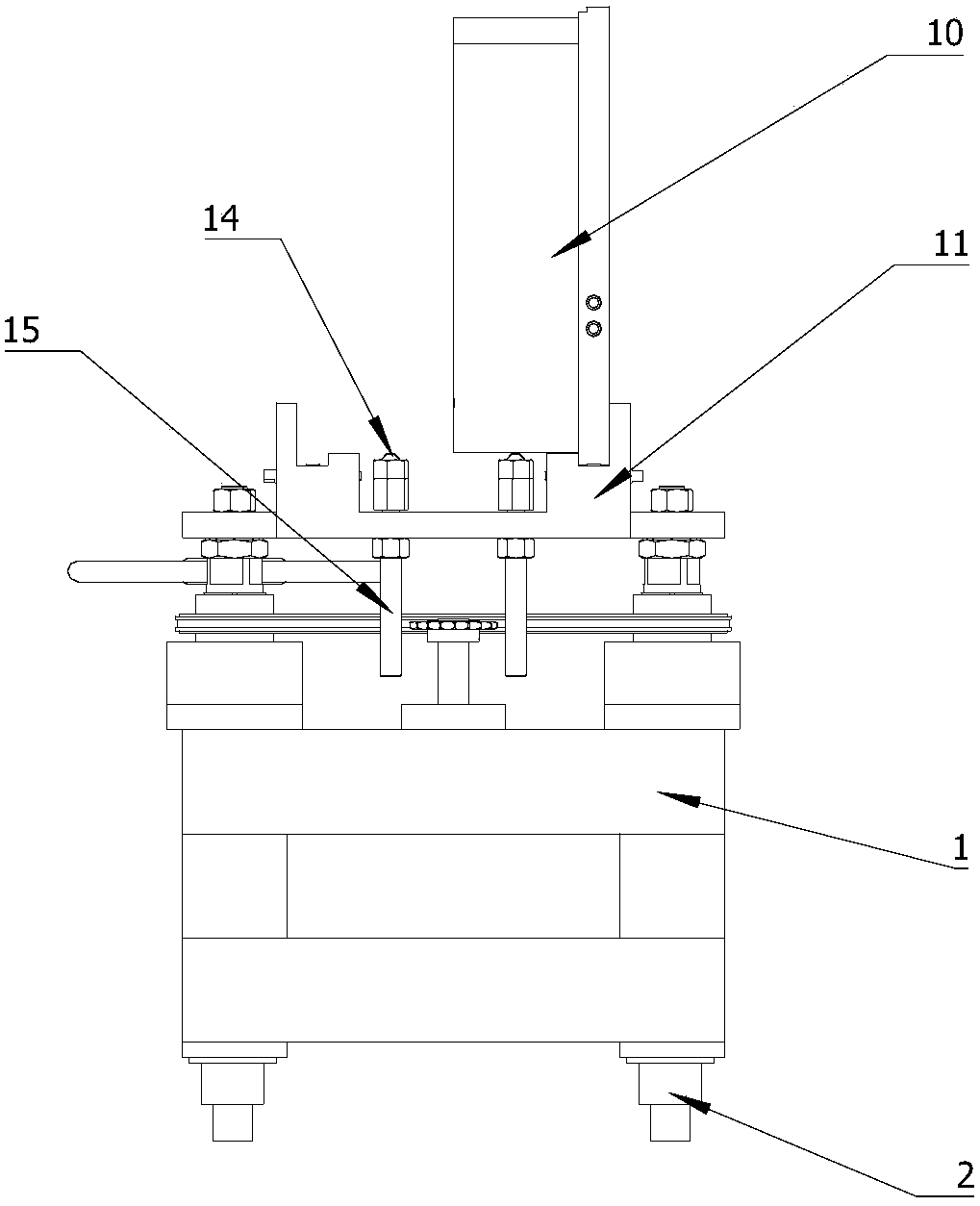

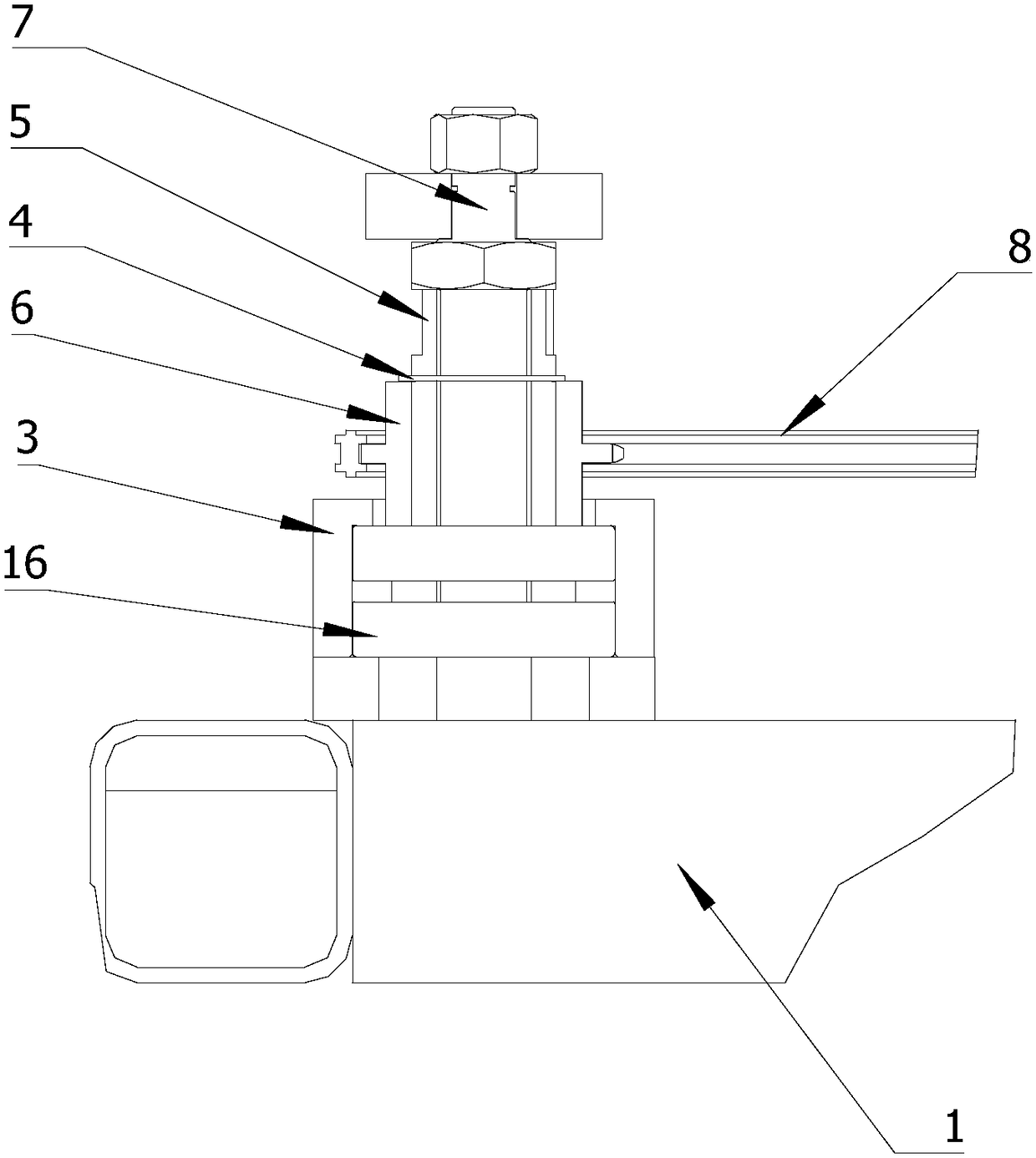

[0032] Such as Figure 1 ~ Figure 5 As shown, a mold installation platform installation mechanism includes a platform support 1 and a platform panel 11. Universal wheels 2 are installed at the four corners of the bottom of the platform support. The platform panel is installed on the platform support through a lifting adjustment mechanism. The mold 10 and the platform panel slide through Mechanism sliding fit.

[0033] The platform bracket adopts a conventional bracket, which is composed of a top frame, a bottom frame and a column. The top frame and the bottom frame are made of columns, and the universal wheels are fixed at the four corners of the bottom frame.

[0034] The lifting adjustment mechanism includes a lifting rod 7, an adjusting nut 5, a roller sprocket 6, a chain 8 and a turntable 9. There are at least three lifting rods (four in this embodiment, respectively located at the 4 corners of the platform bracket). In the method, the lifting rod adopts a screw, the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com