Intelligent assembly and maintenance work vehicle for high-speed EMU

A technology for high-speed EMUs and work vehicles, applied to motor tools, workshop equipment, wrenches, etc., can solve the problems of time-consuming and labor-intensive information, low assembly precision, and inconvenient operation, so as to reduce labor costs, improve work efficiency, and reduce labor costs. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

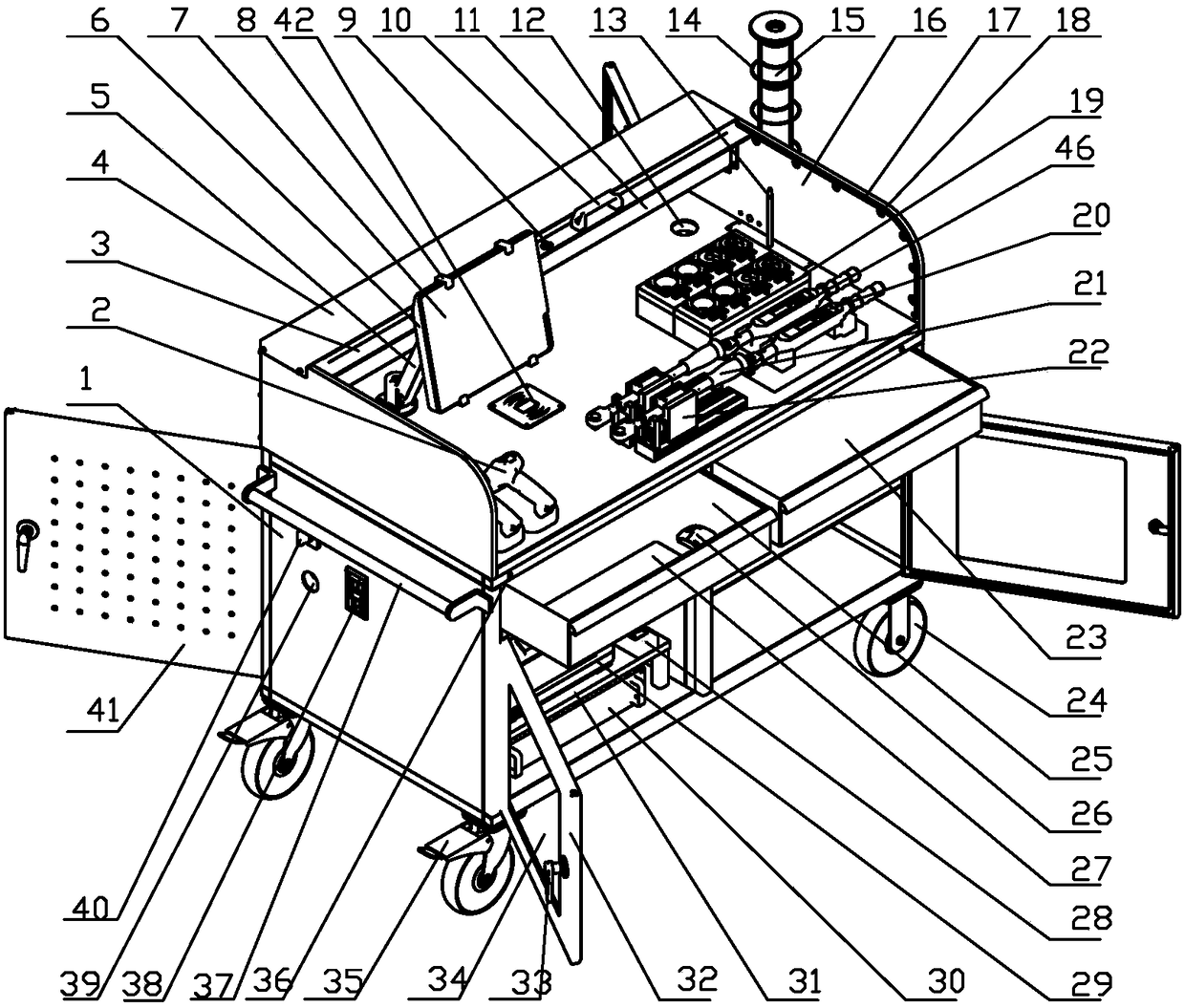

[0019] Refer to attached figure 1 to attach Figure 5 The intelligent assembly and maintenance vehicle for high-speed EMUs of the present invention will be described in detail below.

[0020] The structure of the intelligent assembly and maintenance operation vehicle for high-speed EMUs of the present invention includes a car body 1, a rolling door 3 is arranged on the upper part of the car body 1, two symmetrically arranged fixing plates 16 are arranged on both sides of the rolling door 3, and a rolling door is arranged on the inner side of the fixing plate 16. The guide groove 17, the inside of the guide groove 17 is provided with a roller 18, the outside of the fixed plate 16 on the right side is equipped with a warning light 15, the outside of the warning light 15 is equipped with a protective cover 14, the bottom of the warning light 15 is provided with a multi-interface combination panel 58, the car A folding bracket 5 is installed on the body table, and a display 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com