Reverse scraper tool for reverse stepped hole machining

A technology of reverse scraper and step hole, applied in the field of reverse scraper, can solve the problems of reducing processing auxiliary time, high safety factor, low operation difficulty, etc., and achieve the effect of reducing processing auxiliary time, increasing safety factor and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

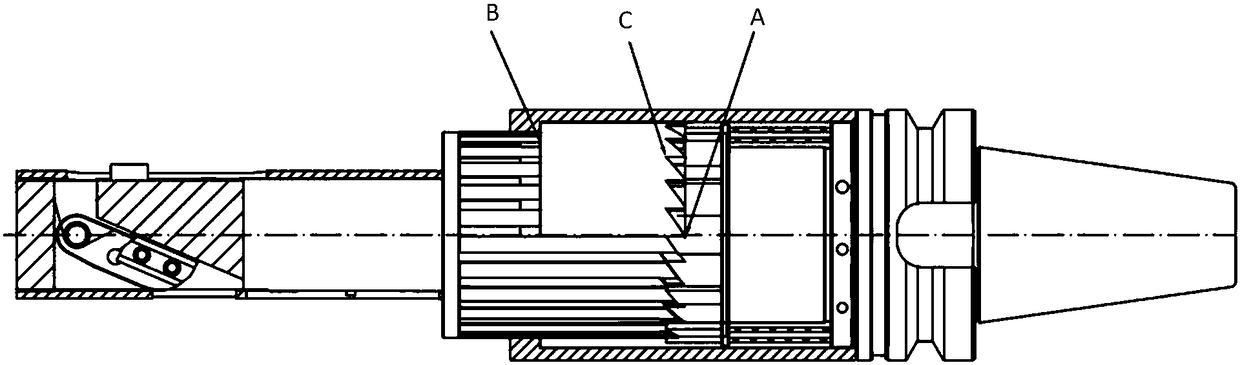

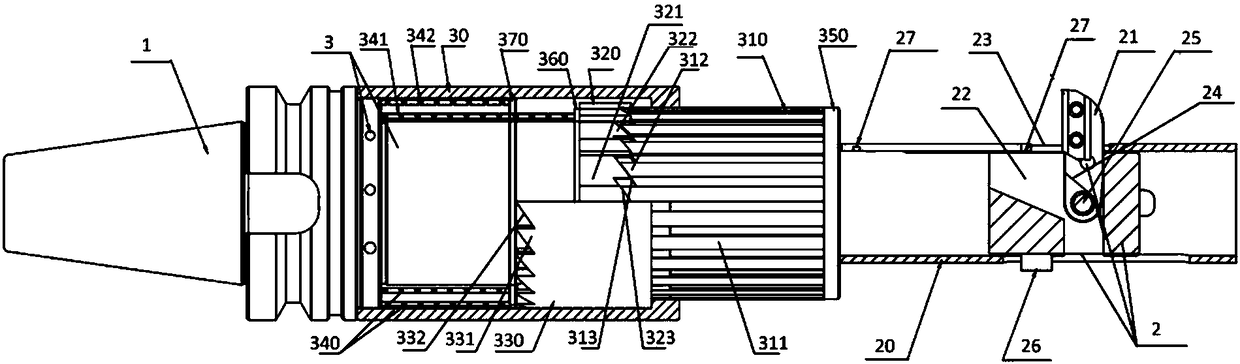

[0055] We first set the anti-scraper in the closed state, see attached figure 1 , the transposition component is in the upper position. There are 24 low keys on the push plate, 12 high keys on the turntable, and 12 shallow key grooves and 12 deep key grooves arranged alternately on the push plate guide assembly. In the upper position, the 24 low keys of the push plate are embedded in the 24 key slots of the push plate guide assembly, while the 12 high rigid points of the turntable are in the inclined slots above the shallow key slots.

[0056] Pass the anti-scraper through the hole to be processed, and give the connecting plate an upward thrust at the hole, so that the connecting plate, push plate, ferrule, and sliding sleeve are connected together upward, so that the push plate pushes the turntable in the push plate guide assembly Move inward toward the cutter body, when the apex of the second key tooth on the turntable reaches the transposition point A, the original support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com