Production system of breast pads

A production system and technology for breast pads, applied in bras, breast bandages, clothing, etc., can solve the problem of milk leakage and other problems, and achieve the effect of improving cutting efficiency, simple and efficient operation, and improving packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

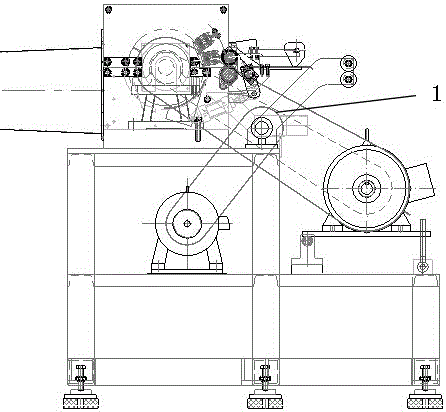

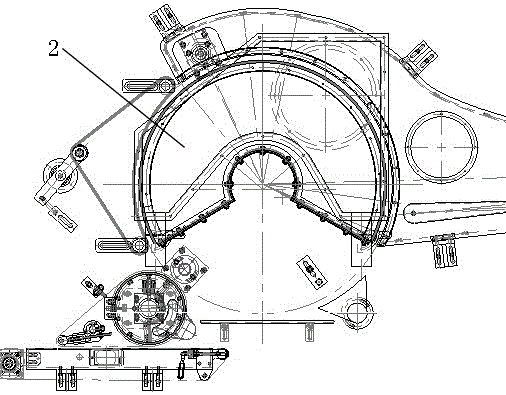

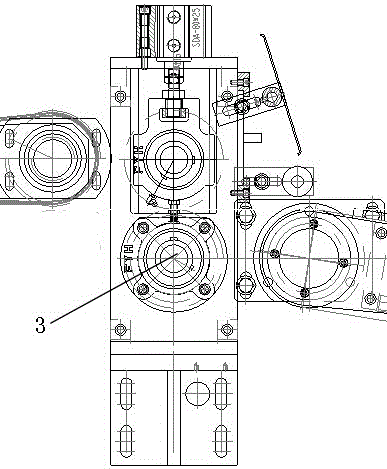

[0044] Such as Figure 1 to Figure 11As shown, a breast pad production system is characterized in that: according to the technological process, it mainly includes the following devices: pulp crushing device 1: used to crush pulp raw materials; cotton core forming device 2: used to shape the crushed pulp raw materials It is the cotton core of the breast pad; toilet paper / dust-free paper wrapping device 3: used to wrap the cotton core of the above-mentioned breast pad with toilet paper or dust-free paper; cotton core cutting device 4: divide the wrapped cotton core cutting; elastic installation device 5: install the elastic on the protective non-woven fabric; diversion groove setting device 6: set the diversion groove on the surface non-woven fabric; release paper composite device 7: for Adhesive rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com