A wind-driven wire feeding device for a cigarette machine with a multi-faceted filter

A wind-powered wire-feeding and cigarette-making machine technology, which is applied to the blanker of the wind-powered wire-feeding device and the field of the wind-forced wire-feeding device of the cigarette machine, can solve the problems of affecting the production efficiency of the equipment, increasing the labor intensity of the workers, and the easy blockage of the filter screen, etc., and achieve ventilation The area is maximized, the cleaning work is easy and simple, and the effect of improving the driving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

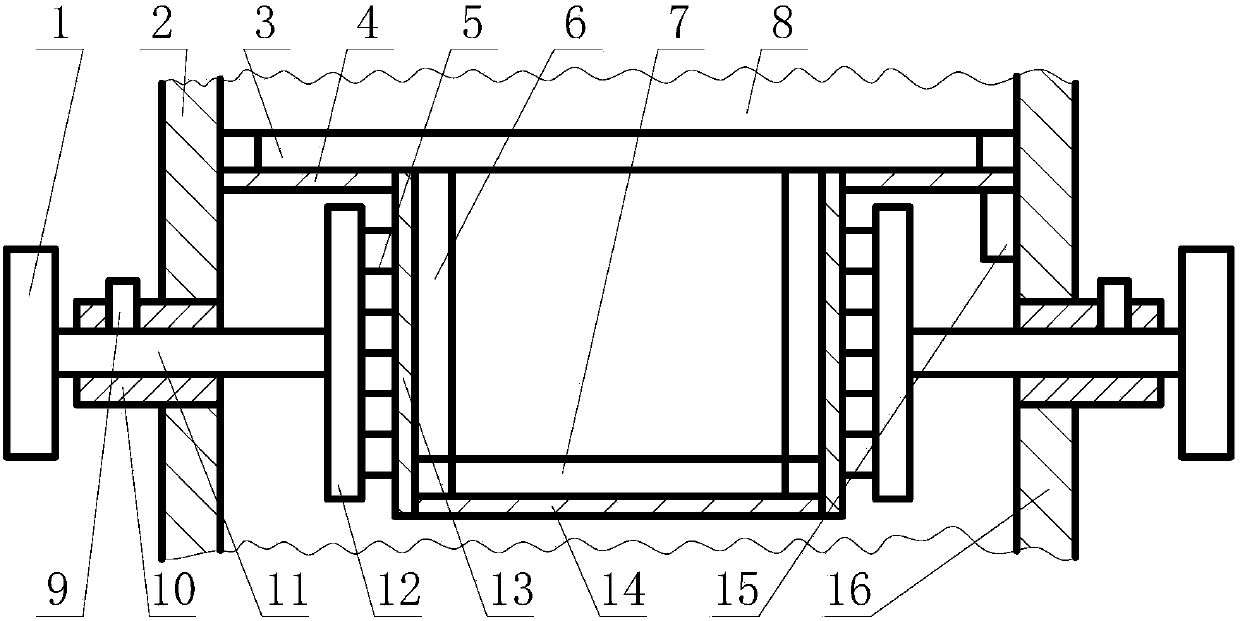

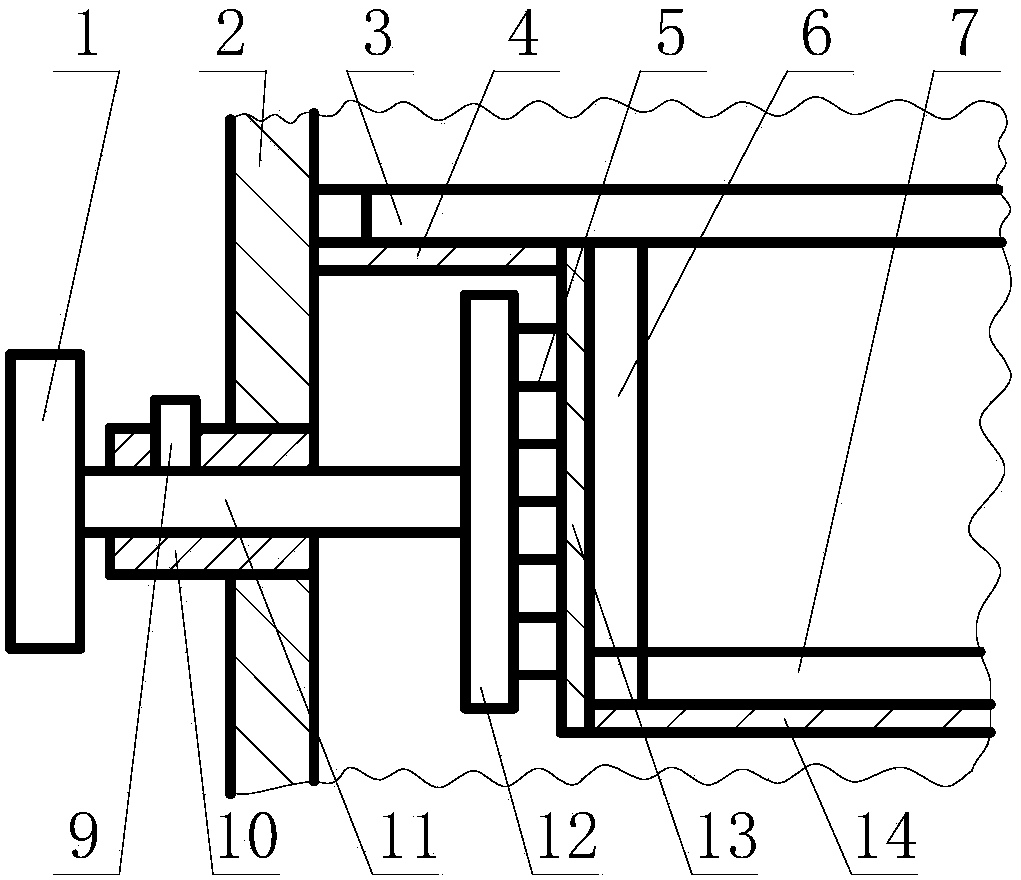

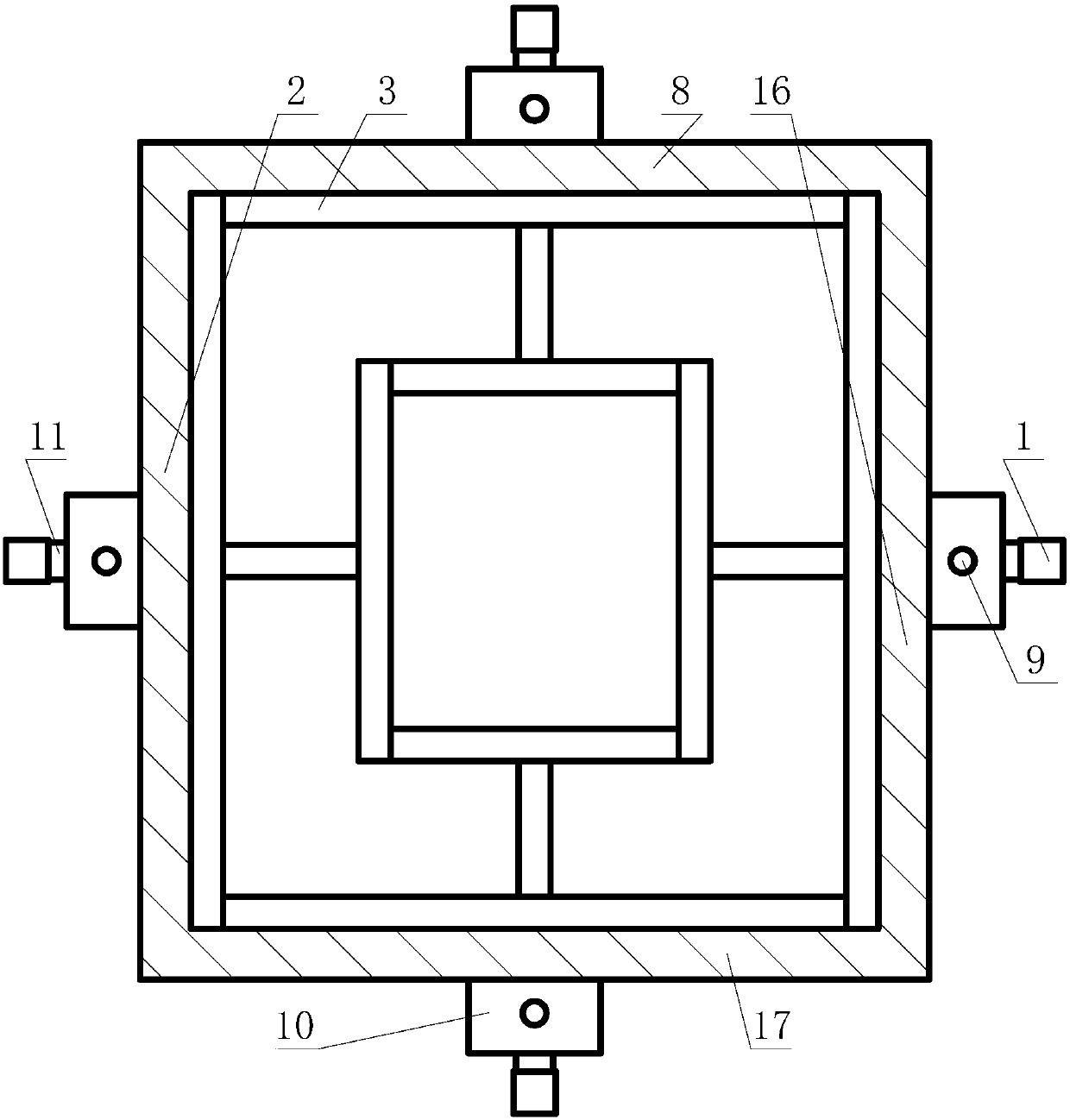

[0024] Combine below Figure 1 to Figure 8 , to further illustrate the present invention: a cigarette machine wind-powered wire feeding device with multi-faceted filter screens, including a feeder, the space surrounded by the main body of the feeder is cuboid, with a left side wall 2, a right side wall 16. The front side wall 8 and the rear side wall 17, a filter screen is arranged inside the feeder, and the feature is that: the filter screen is composed of a frame and a steel wire mesh; the frame is composed of a main frame 3, four vertical The straight bar 6 and a sub-frame 7 are composed; the main frame 3 includes a large frame 301, a small frame 302 and a connecting rod 303; the large frame 301 is composed of two horizontal bars 30101 and two horizontal longitudinal bars 30102 are connected to form a rectangular frame, and the small frame 302 is connected to form a rectangular frame by two short horizontal bars 30201 and two short vertical bars 30202 in the horizontal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com