Fast clamping pressure plate clamp

A plate clamping and clamping technology, applied in clamping, positioning devices, manufacturing tools, etc., can solve the problems of high failure rate, high cost of replacing parts, complex structure, etc., and achieve rapid positioning, simple structure, and convenient retrieval. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

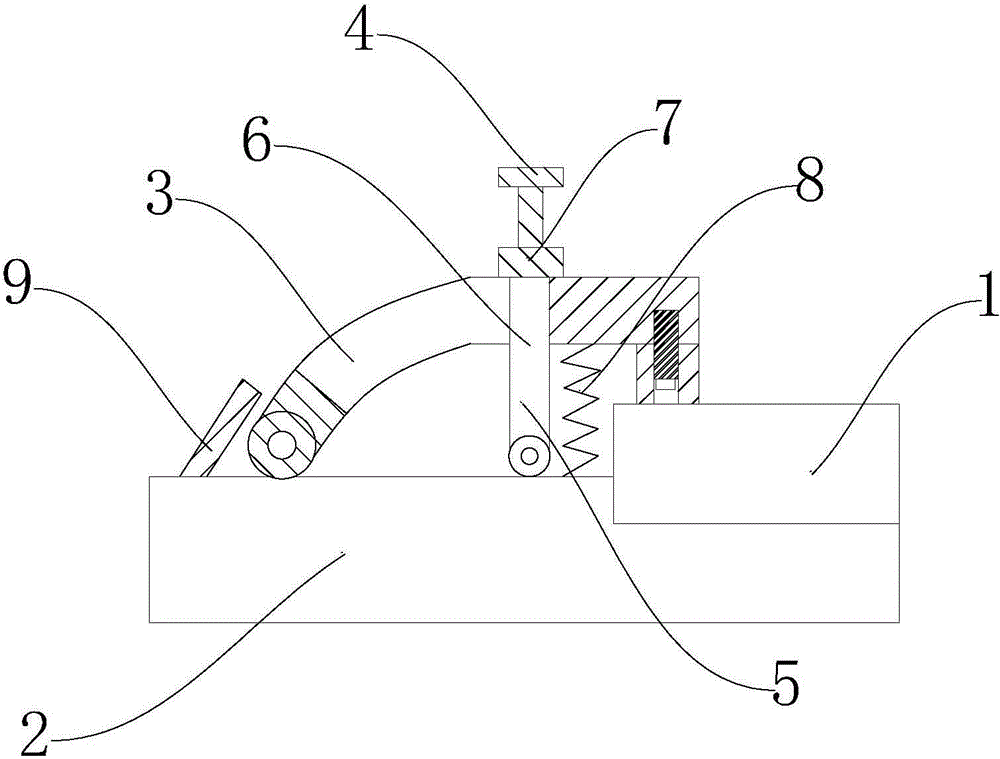

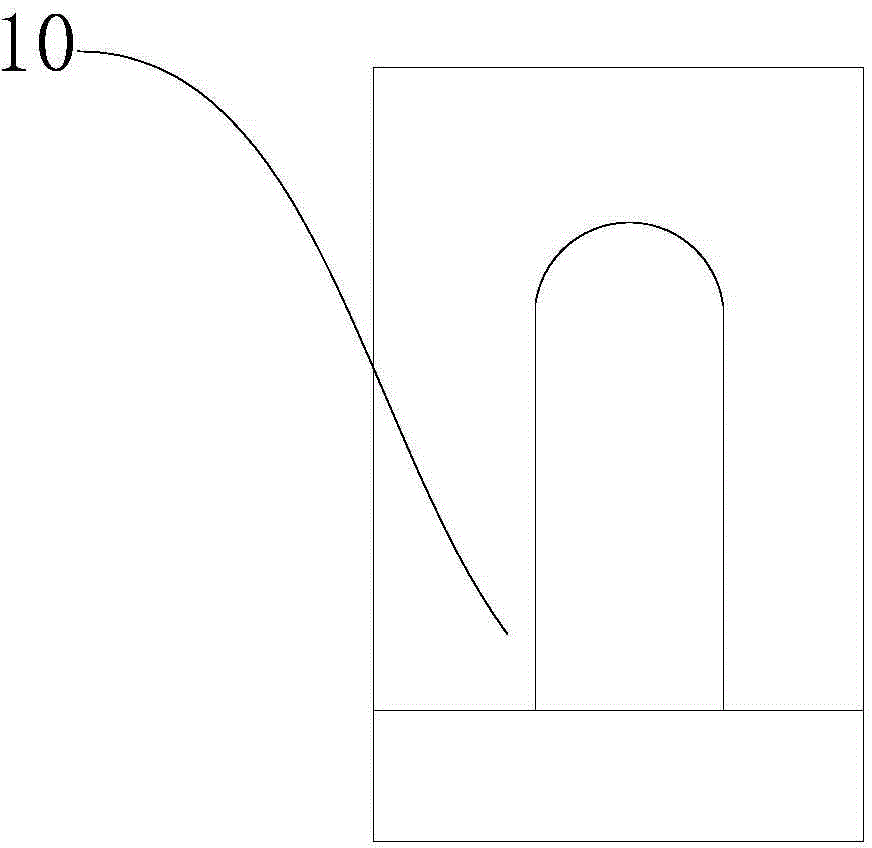

[0011] see figure 1 The described clamping clamp for fast clamping includes a clamping table 2, the clamping table 2 is provided with a stepped surface for placing the workpiece 1, and an arc-shaped pressing plate 10 is also hingedly arranged on the clamping table 2, and the arc-shaped A long hole is provided in the middle of the pressing plate 10, the arc-shaped pressing plate 10 includes an arc-shaped portion 3 and a horizontal portion, a pressing piece 5 is movably arranged in the long hole, and the pressing piece 5 includes a handle portion 4 and a fastening portion 7 and the hinged part 6, the clamp table 2 is provided with an ejection spring 8 for ejecting the arc-shaped pressing plate 10, the horizontal part of the arc-shaped pressing plate 10 includes a detachable pressing part, and the pressing part is connected by a screw Connected to the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com