Lubricant injector

A lubricating oil and injector technology, which is applied in the direction of lubricating oil control valves, lubricating pumps, lubricating parts, etc., can solve problems such as interruption of injection ports, reduced fluidity of lubricating grease, and inability to inject smoothly, so as to overcome the flow of lubricating oil The difference in quantity, the effect of reducing oil separation degree and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, a first embodiment to which the present invention is applied will be described in detail with reference to the drawings.

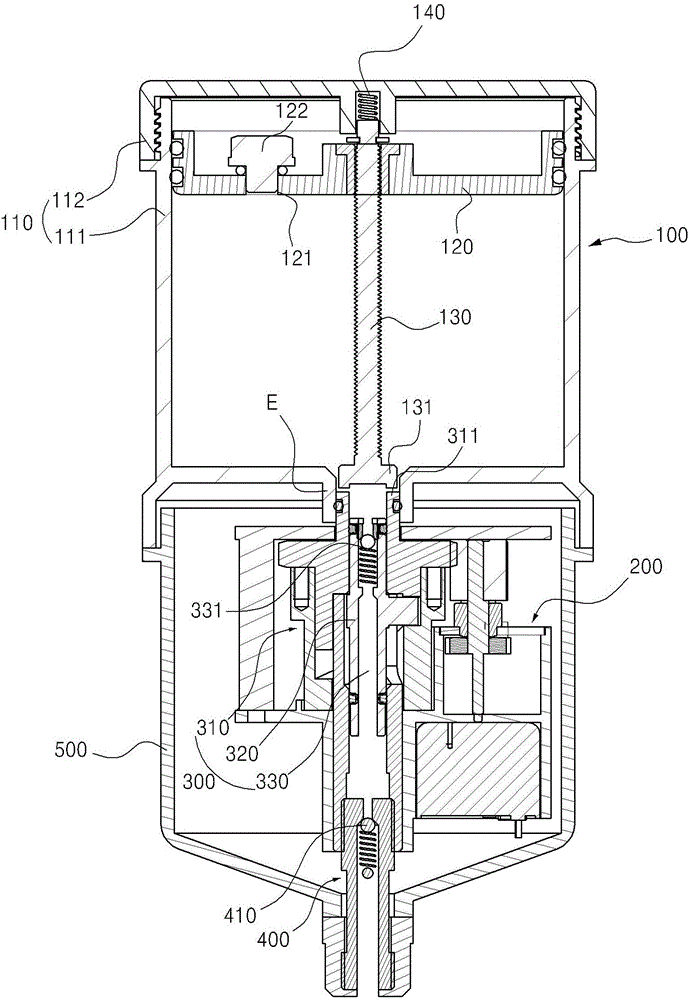

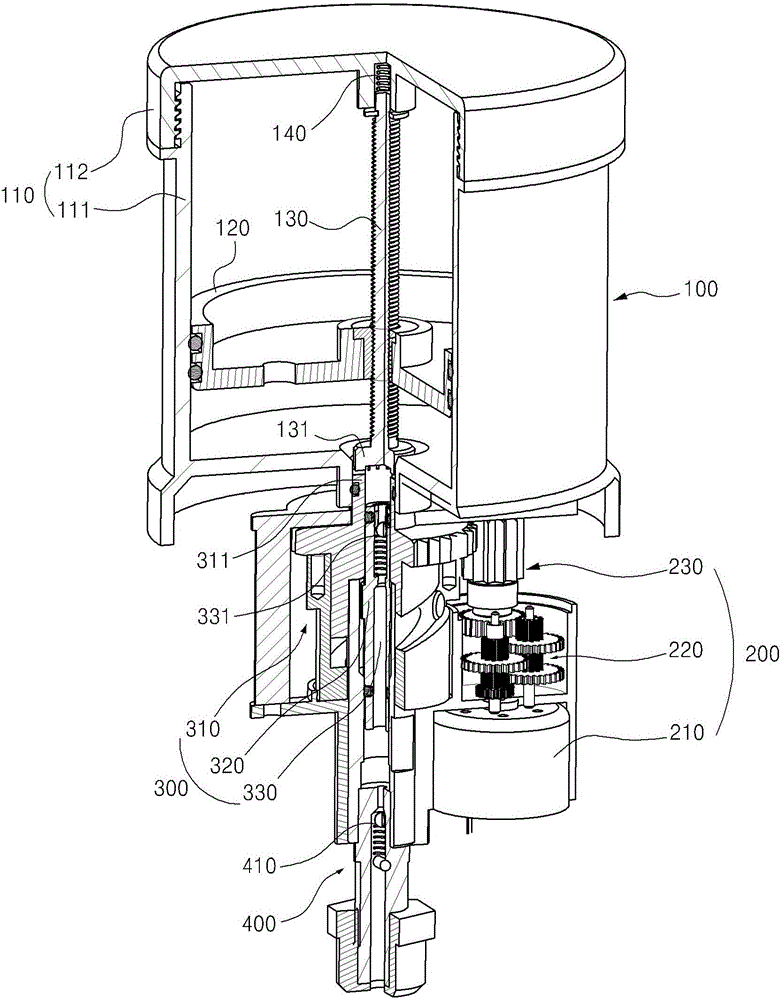

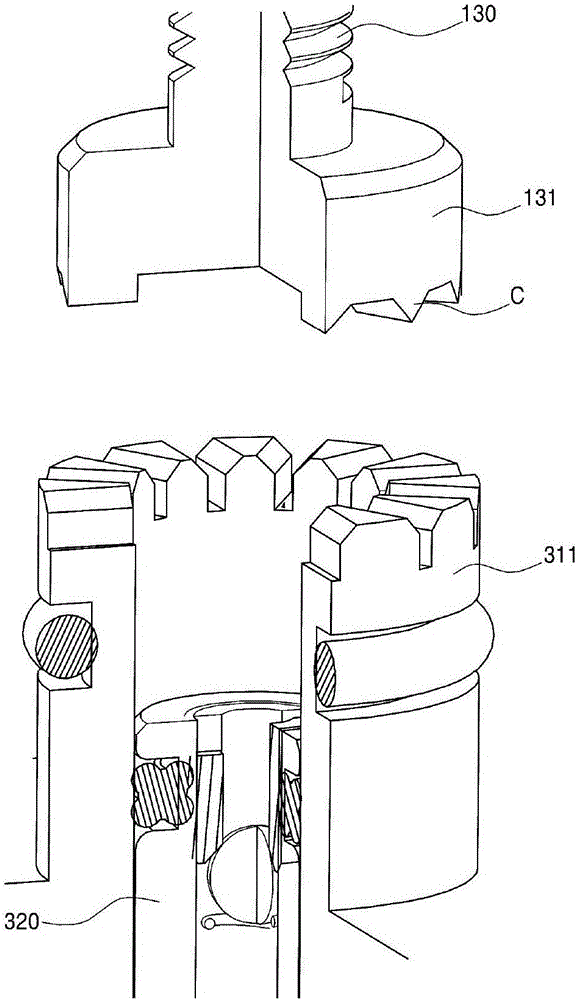

[0032] figure 1 and figure 2 They are respectively a sectional view and a perspective view showing a lubricating oil injector applicable to the first embodiment of the present invention. As shown in the figure, the present invention includes a storage part 100 , a power generation part 200 and a discharge part 300 .

[0033] First, the above-mentioned storage part 100 is filled with lubricating oil that needs to be used at the position where mechanical friction occurs, so as to press the lubricating oil into the discharge part 300, including: storage chamber 110, piston 120, screw shaft 130, driven gear 131 and the elastic support member 140.

[0034] The storage chamber 100 is used to provide a space for filling and storing lubricating oil, and includes: a main body 111 and an outer cover 112 . The main body 111 provides a space for filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com