Protection-type AC variable frequency motor for electric fork-lift truck

An AC frequency conversion and electric forklift technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems that the safety cannot be guaranteed, cannot meet the actual needs, and the overall structure of the motor is complicated, so as to achieve stable and firm interconnection, loading and unloading Convenient and fast, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

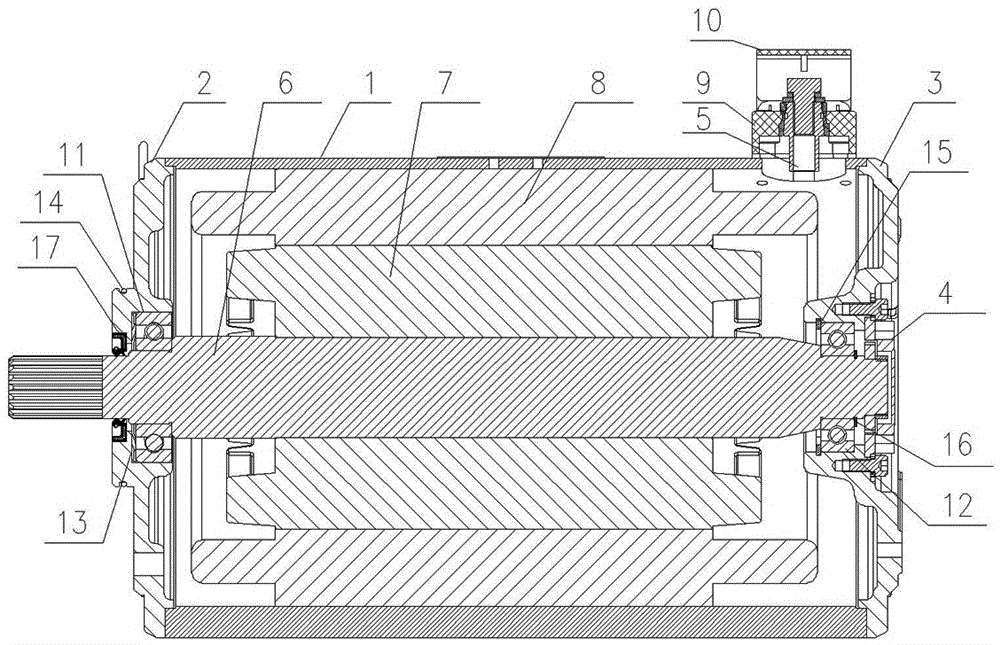

[0027] Such as figure 1 As shown, a protective AC frequency conversion motor for an electric forklift in this embodiment includes: a base 1, a front end cover 2, a rear end cover 3, an encoder 4, a temperature sensor 5, a main shaft 6, a rotor assembly 7, and a stator assembly 8. Wiring board 9, wiring board cover 10, first bearing 11, second bearing 12, wave spring piece 13, O-ring 14, circlip 15 for hole, circlip 16 for shaft and oil seal 17.

[0028] The connection relationship of the above-mentioned components is as follows: the main shaft 6 runs through the outer shell formed by the front end cover 2, the base 1 and the rear end cover 3, and a terminal block 9 is fixedly connected to one end of the base 1. A temperature sensor 5 is provided inside the wiring board 9, and a wiring board cover 10 is provided outside; the rotor assembly 7 is connected with the main shaft 6 and the stator assembly 8 in the base 1, and the two ends of the main shaft 6 are respectively sleeved ...

Embodiment 2

[0032] Such as figure 1 As shown, a protective AC frequency conversion motor for an electric forklift in this embodiment includes: a base 1, a front end cover 2, a rear end cover 3, an encoder 4, a temperature sensor 5, a main shaft 6, a rotor assembly 7, and a stator assembly 8. Terminal board 9, terminal board cover 10, first bearing 11, second bearing 12, wave spring sheet 13, circlip 15 for hole, circlip 16 for shaft and oil seal 17.

[0033] The connection relationship of the above-mentioned components is as follows: the main shaft 6 runs through the outer shell formed by the front end cover 2, the base 1 and the rear end cover 3, and a terminal block 9 is fixedly connected to one end of the base 1. A temperature sensor 5 is provided inside the wiring board 9, and a wiring board cover 10 is provided outside; the rotor assembly 7 is connected with the main shaft 6 and the stator assembly 7 in the base 1, and the two ends of the main shaft 6 are respectively sleeved with T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com