Device for skinning electric wire cable

A wire and cable hob technology, which is applied in the direction of cable installation, cable installation device, disassembly/armored cable equipment, etc., can solve the problems of poor peeling effect, accidental finger scratches, low safety, etc., to achieve peeling Good effect, quick action, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

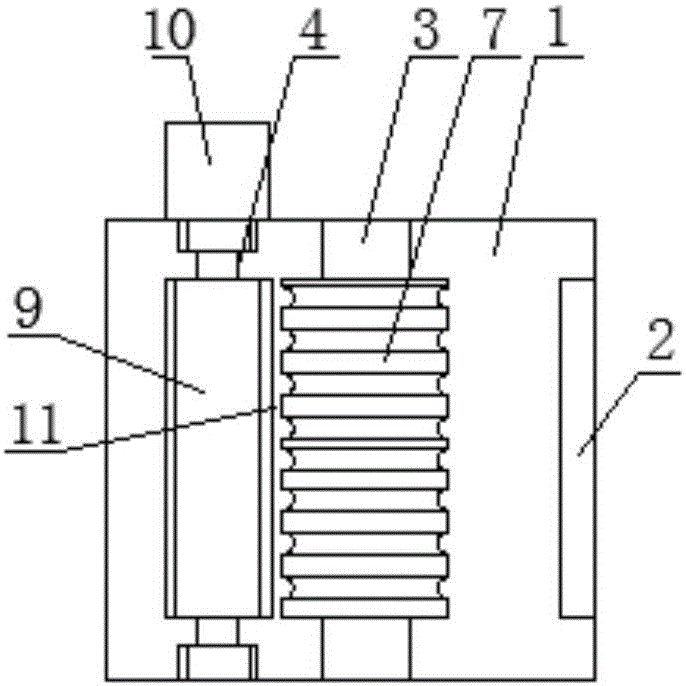

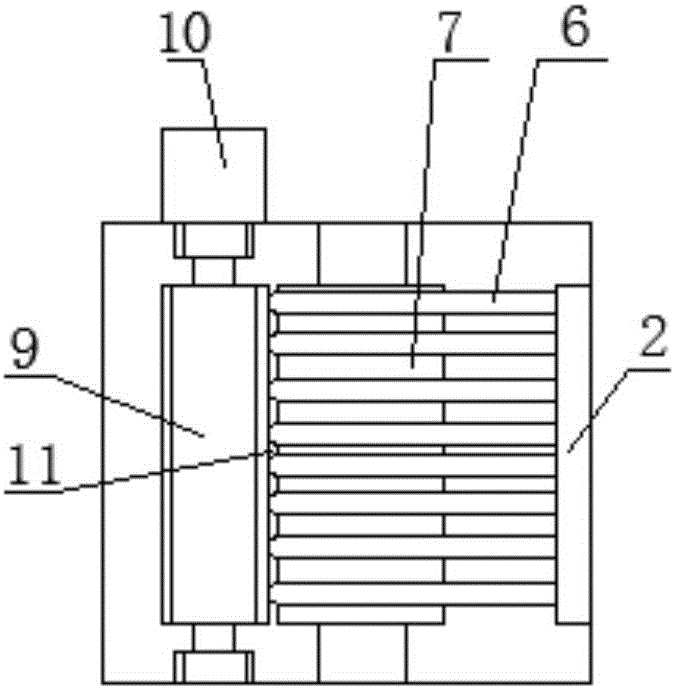

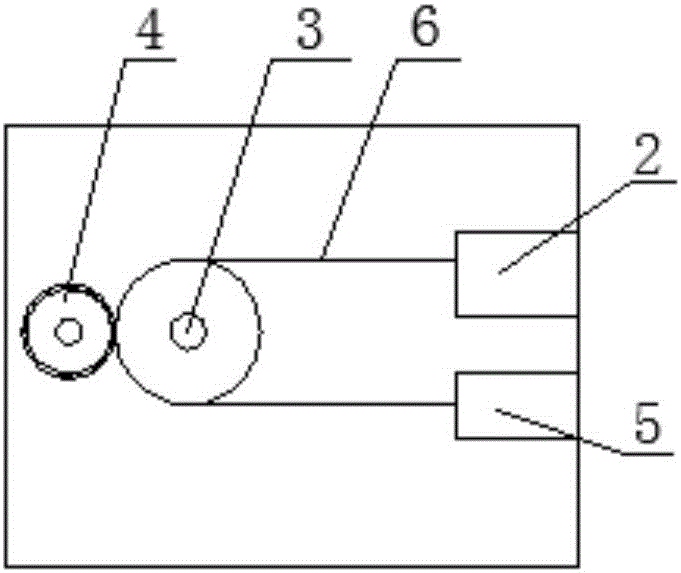

[0031] like Figure 1-3 , 5 and 6, a device for stripping wires and cables, including a support 1, on which a feeding mechanism 2, an auxiliary stripping mechanism 3 and a stripping mechanism 4 are successively arranged, and the auxiliary stripping mechanism 3 and the stripping mechanism There is a gap 11 between the 4, and a traction mechanism 5 is provided directly below the feeding mechanism 2, and the wire and cable 6 pass through the feeding mechanism 2, the gap 11 and the traction mechanism 5 in turn,

[0032] The auxiliary peeling mechanism 3 includes a roller shaft 7, which is rotatably connected to the support 1, and the outer surface of the roller shaft 7 is provided with grooves 8 distributed along the circumferential direction, and the grooves 8 are parallel and coaxially arranged;

[0033] Peeling mechanism 4 comprises a hob 9, and hob 9 is by a motor 10, and the output end of motor 10 is connected with an end of hob 9, and gap 11 is positioned between hob 9 and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com