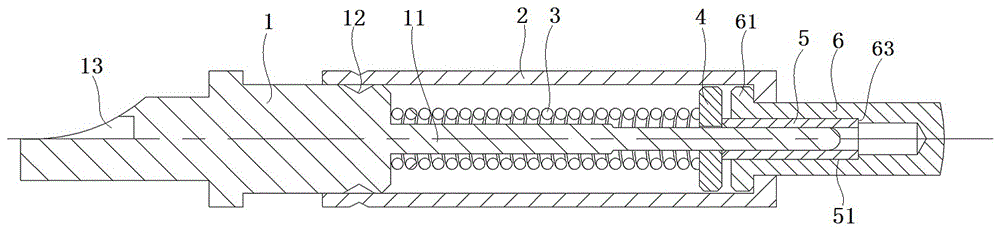

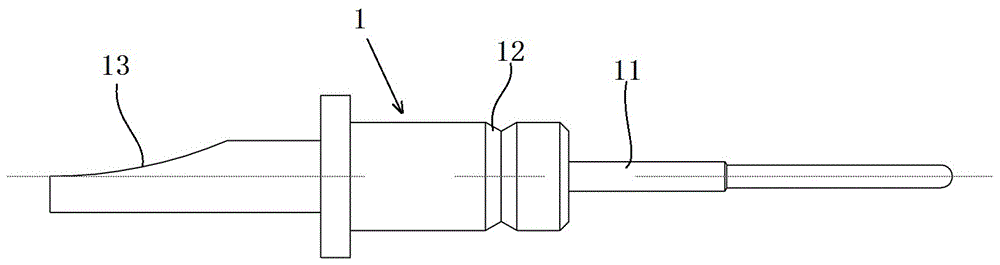

Elastic contact part and electric connector employing same

An elastic contact piece and elastic piece technology, applied in the direction of contact parts, etc., can solve the problems of reducing the reliability of the electrical connection between the moving contact and the outer casing, and achieve the effects of ensuring reliability, increasing service life and enhancing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0036] The second specific embodiment of the elastic contact piece of the present invention: the difference from the first embodiment is that at least one elastic claw is provided at the rear end of the contact piece body, and the elastic claw extends backward along the axial direction of the contact piece body and can radially To shrink, the claws surround the socket for inserting the pins, and the claws form a shrinking structure.

specific Embodiment 3

[0037] The third specific embodiment of the elastic contact piece of the present invention: the difference from the first embodiment is that the conductive structure at the rear end of the connecting sleeve is the valgus edge at the rear end of the connecting sleeve, and the spring transmits the elastic force to the connecting sleeve through the valgus edge superior.

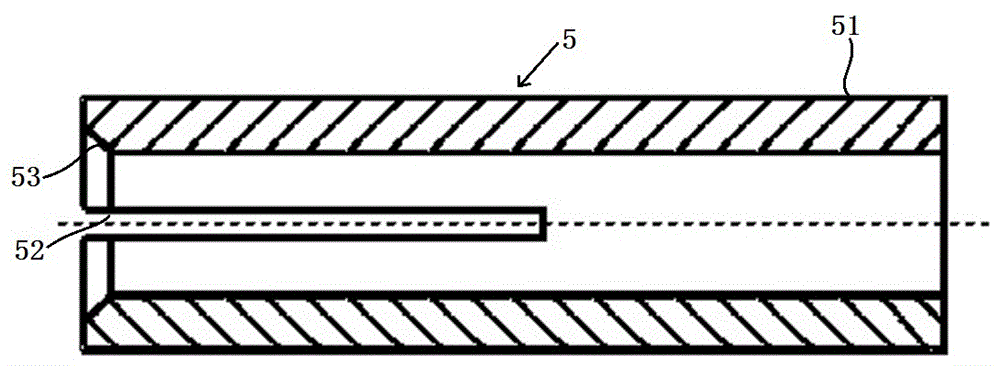

[0038] Embodiment 4 of the elastic contact piece of the present invention: The difference from Embodiment 1 is that a mounting structure for installing a spring is provided on the inner wall of the sheath, and the spring is fixed on the sheath through the mounting structure.

[0039] A specific embodiment of the electrical connector of the present invention, the electrical connector includes an electrical connector housing and a contact in the housing, the structure of the contact is the same as that of the elastic contact in the above embodiment of the elastic contact, and the Let me repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com