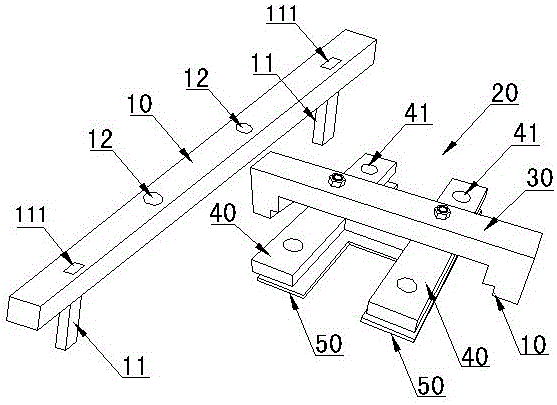

Capacitor production positioning device

A positioning device and capacitor technology, which is applied in packaging capacitor devices, capacitors, capacitor manufacturing, etc., can solve the problems of positioning offset, inconvenient installation and positioning operations, and different height positions, and achieve high production efficiency and high one-time pass rate. , Positioning the effect of high verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

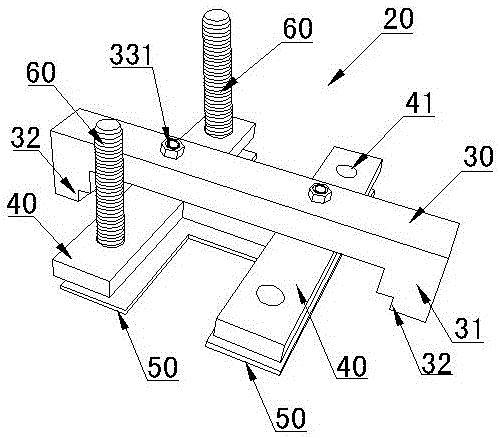

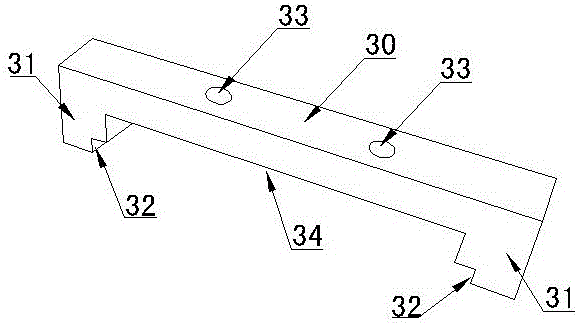

[0023] Figure 5 In the shown embodiment, the electrode base fixing plate 50 for fixing the capacitor electrode lead-out terminal base is provided under the electrode lead-out terminal positioning plate 30, and the electrode base fixing plate 50 is provided with four square holes 51 for fixing and fixing the capacitor electrode lead-out terminal base , the distribution of the four square holes 51 is aligned with the guide limit hole of the electrode lead-out terminal located above, and the bottom end of the capacitor electrode lead-out terminal is installed and fixed in the square hole 51, which not only quickly and effectively locates the position of the electrode lead-out terminal but also It quickly and effectively ensures the height and dimension consistency of the packaged capacitor electrode lead-out terminals in terms of the height of the lead-out terminals, prevents unevenness of each electrode lead-out terminal of the packaged capacitor, and effectively improves the ov...

Embodiment 3

[0025] Positioning bar 10 two ends places are provided with rectangular vertical arm mounting hole, and the length direction of vertical arm mounting hole is consistent with the lengthwise direction of positioning bar, and the limit vertical arm upper end is slidably located in the rectangular vertical arm mounting hole, vertical The arm mounting hole is provided with a sliding limit groove on the upper end of the limit vertical arm in the length direction, and a compression spring is arranged in the rectangular vertical arm mounting hole on the outer side of the positioning rod. One end of the compression spring touches the upper end of the limit vertical arm and the other One end touches the mounting hole of the vertical arm to form an installation connection structure in which the distance between the two limiting vertical arms at the two ends of the positioning rod is adjustable. Others are identical with embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com