Local resonance acoustic black hole structure

A local resonance and acoustic technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of reducing the frequency of action, the low-frequency black hole effect is difficult to achieve, etc., and achieve the effect of easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

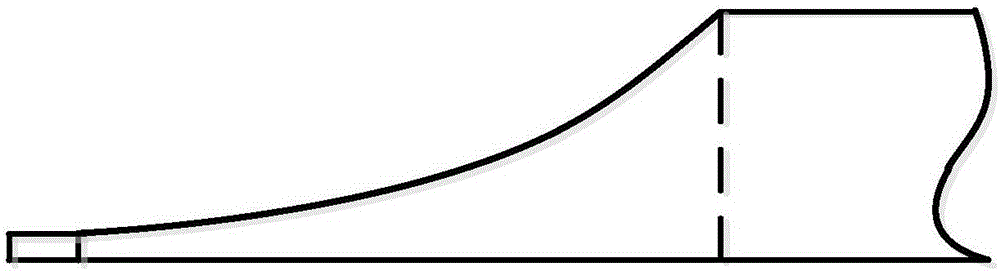

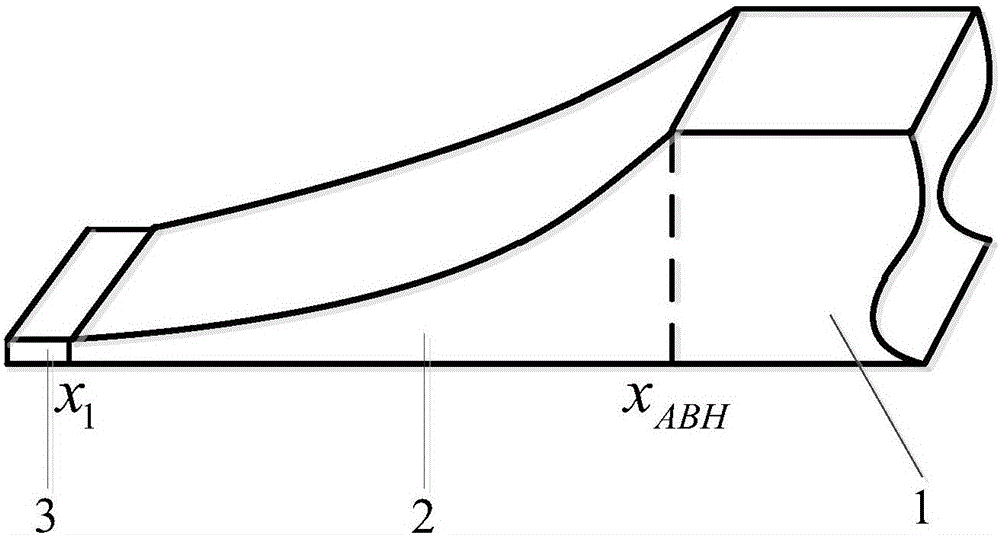

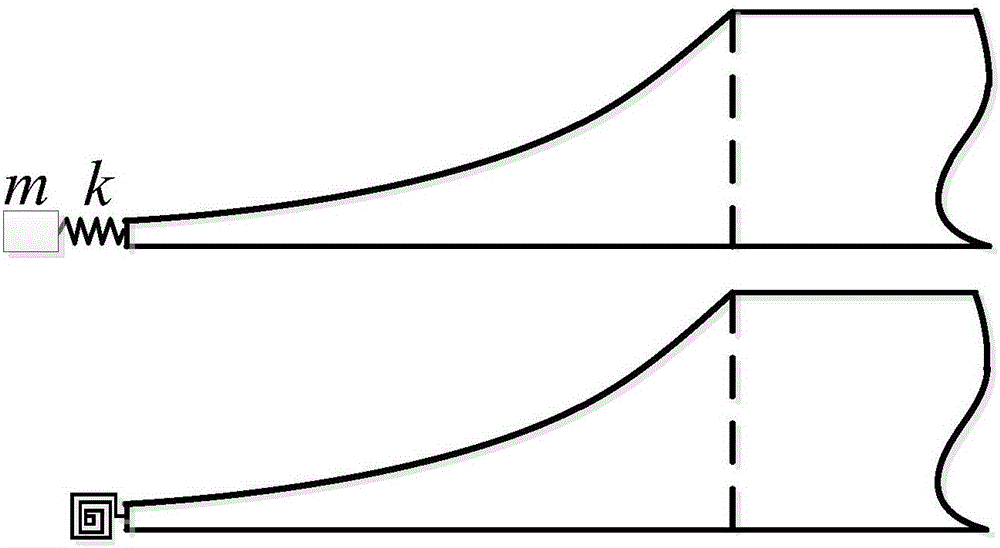

[0021] The local resonance acoustic black hole structure of the present invention includes a plate structure 1 and an acoustic black hole structure 2 connected to the plate structure 1, wherein the distance between the front and rear surfaces of the plate structure 1 is fixed from right to left, and the distance between the upper and lower surfaces of the plate structure 1 It is also fixed from right to left. The distance between the front and back surfaces of the acoustic black hole structure 2 is fixed from right to left, and the distance between the upper and lower surfaces of the acoustic black hole structure 2 is from right to left in the exponential function form h(x)=ex m (the exponent m is not less than 2) decreases gradually, and the distance between the upper and lower surfaces of the rightmost end of the acoustic black hole structure 2 is equal to the distance between the upper and lower surfaces of the plate structure 1. A local vibrator 4 is connected to the leftm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com