Single-joint rock mass flow-solid coupling testing system and method

A test system and single-fissure technology, applied in the field of single-fissure rock mass flow test and rock mass mechanical test, can solve the problem that the waterproof effect of the test device is not ideal, the normal use of the triaxial testing machine is affected, and it is difficult to ensure the sealing effect of the shear box. and other problems, to achieve the effect of complete functions, simple structure, loose size and shape requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

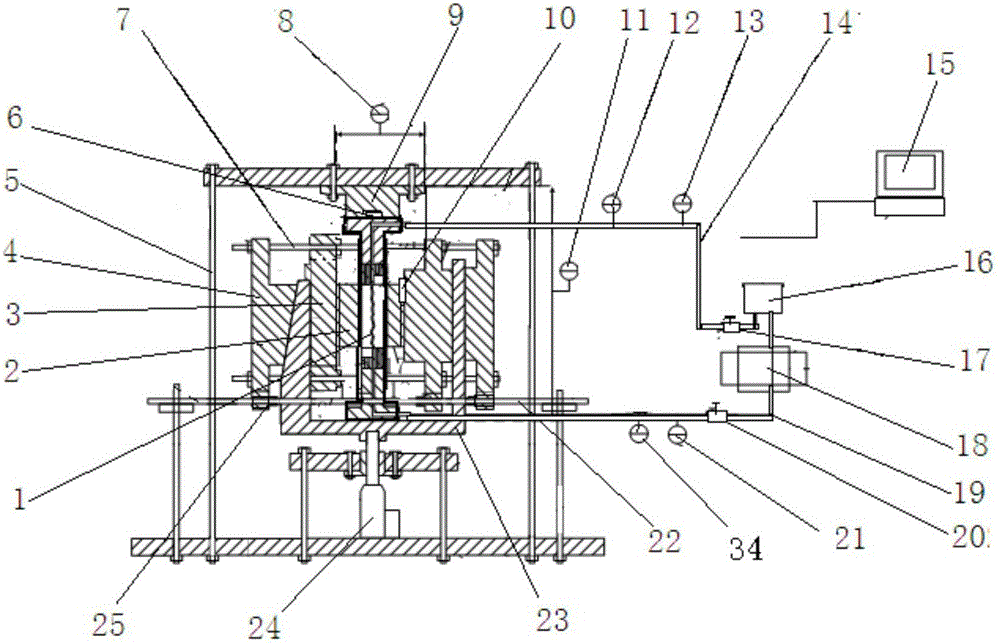

[0035] Such as figure 1 As shown, a single-crack rock mass fluid-solid coupling test system is composed of a sample shearing device, a stress loading device, an osmotic pressure servo device, and a data acquisition and processing device;

[0036] Such as figure 2As shown, the sample shearing device is composed of an upper indenter 31 placed on the top of the rock test piece 1, an upper rigid gasket 30, a lower indenter 26 placed at the bottom of the rock test piece 1, and a lower rigid gasket 27; The sections of the upper indenter 31, the upper rigid gasket 30, the lower indenter 26, and the lower rigid gasket 27 are consistent with the section of the rock specimen, and the upper indenter 31 and the upper rigid gasket are sequentially sealed by the water-sealing rubber sleeve 29. Sheet 30, rock test piece 1, lower rigid gasket 27, and lower indenter 26 are set together to form a columnar body; The water inlet channel 33, the upper indenter 31, and the upper rigid gasket 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com