Drying and calcination process of a new type of one-piece extruded denitrification catalyst for diesel vehicles

A technology of denitrification catalyst and calcination process, which is applied in the field of dry calcination process of a new type of extruded diesel vehicle denitrification catalyst, can solve the problem of catalyst strength, high requirements for physical defect indicators, honeycomb denitrification catalyst calcination process can not achieve the expected effect, Low pass rate of finished products and other problems, to achieve uniform and stable air circulation, guarantee product pass rate, and avoid dry cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

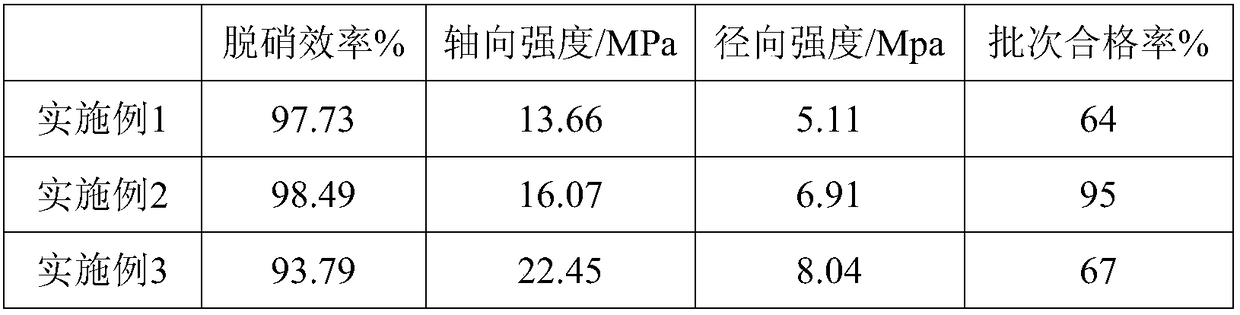

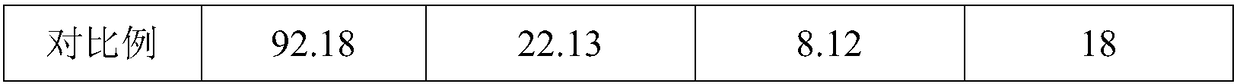

Examples

Embodiment 1

[0027] 1. The first-level drying process of the catalyst is carried out in the drying room with the above-mentioned air inlet and outlet control, placed on the rack car, and each layer is discharged horizontally, evenly arranged, and the following temperature curve is implemented:

[0028] temperature / ℃

30

35

40

43

45

48

50

55

60

time / h

24

24

24

24

24

24

24

24

24

[0029] 2. The catalyst calcination process is carried out in a mesh belt kiln with air inlet in the form of a wind cone. The mesh belt kiln has a total of 30 temperature zones, and the temperature zones can also be increased or decreased appropriately, but the trend of the execution temperature curve should be consistent. The mesh belt speed is 2.4m / h, and the following temperature curve is executed:

[0030] zone 1

Embodiment 2

[0032] 1. The first-level drying process of the catalyst is carried out in the drying room with the above-mentioned air inlet and outlet control, placed on the rack car, and each layer is discharged horizontally, evenly arranged, and the following temperature curve is implemented:

[0033] temperature / ℃

30

35

40

43

45

48

50

55

60

time / h

48

24

24

24

24

24

48

24

24

[0034] 2. The catalyst calcination process is carried out in a mesh belt kiln with air inlet in the form of a wind cone. The mesh belt kiln has a total of 30 temperature zones, the mesh belt speed is 2.4m / h, and the following temperature curve is implemented:

[0035] zone 1

Embodiment 3

[0037] 1. The first-level drying process of the catalyst is carried out in the drying room with the above-mentioned air inlet and outlet control, placed on the rack car, and each layer is discharged horizontally, evenly arranged, and the following temperature curve is implemented:

[0038] temperature / ℃

30

35

40

43

45

48

50

55

60

time / h

48

48

24

48

24

48

48

24

24

[0039] 2. The catalyst calcination process is carried out in a mesh belt kiln with air inlet in the form of a wind cone. The mesh belt kiln has a total of 30 temperature zones, the mesh belt speed is 2.4m / h, and the following temperature curve is implemented:

[0040] zone 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com