Mechanical seal ring with maple-leaf-like grooves

A technology of mechanical seals and seal rings, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of non-bidirectional rotation of the spiral groove, poor dynamic pressure effect, and unsatisfactory sealing performance, so as to achieve stable operation and good conduction. Flow effect, small leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

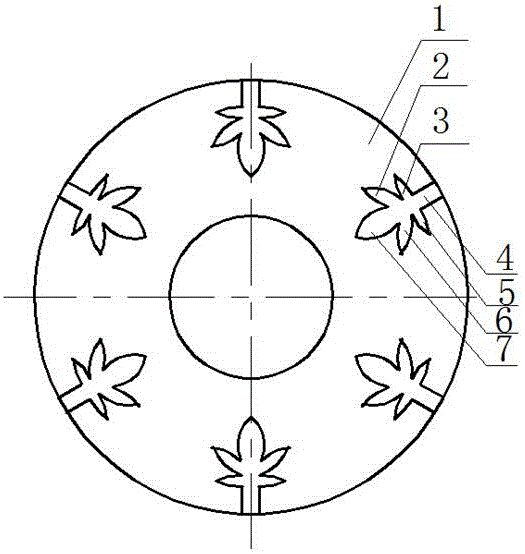

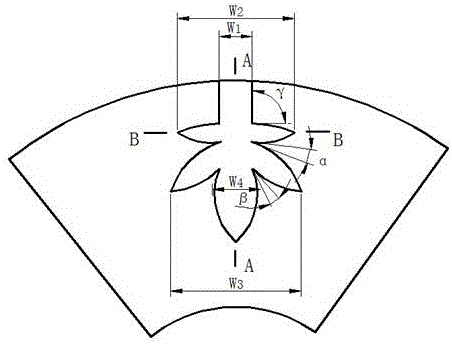

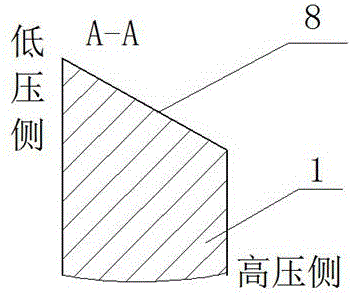

[0026] Such as figure 1 , figure 2 with image 3 As shown, a mechanical seal ring with imitation maple leaf-shaped grooves has six imitation maple leaf-shaped grooves evenly distributed in the circumferential direction of the end face of the seal ring 1, and the imitation maple leaf-shaped grooves are composed of one radial linear groove and five arc grooves (arc groove Ⅰ2-arc groove Ⅴ7), arc groove Ⅰ2-arc groove Ⅳ6 are symmetrically distributed on both sides of the radial linear groove 4, the arc groove Ⅰ2 is the same as the arc groove Ⅳ6, and the arc groove Ⅱ3 is the same as the arc groove The line groove III5 is the same, the arc groove V7 is connected with the radial linear groove 4 close to the inner diameter end of the sealing ring 1, the high pressure side is at the outer diameter of the sealing ring 1, and the radial linear groove 4 opens at the edge of the outer diameter of the sealing ring 1. The maple leaf-shaped groove is radially symmetrical to the central axis...

Embodiment 2

[0034] Referring to the structure of Embodiment 1, the arc grooves are replaced with rectangular grooves.

[0035] A mechanical seal ring with imitation maple leaf-shaped grooves, two imitation maple leaf-shaped grooves are evenly distributed in the circumferential direction of the end face of the seal ring, and the imitation maple leaf-shaped grooves are composed of one radial linear groove and five rectangular grooves (rectangular groove Ⅰ- Rectangular groove V), rectangular groove I-rectangular groove IV are symmetrically distributed on both sides of the radial linear groove, rectangular groove I is the same as rectangular groove IV, rectangular groove II is the same as rectangular groove III, and rectangular groove V is close to the radial linear groove The inner diameter end of the sealing ring is connected, the high-pressure side is on the outer diameter of the sealing ring, and the radial linear groove opens on the edge of the outer diameter of the sealing ring. The edg...

Embodiment 3

[0040] Referring to the structure of embodiment 1, the arc groove is replaced with a spiral groove.

[0041]A mechanical seal ring with maple-leaf-like grooves, 50 maple-leaf-like grooves are evenly distributed in the circumferential direction of the end face of the seal ring, and the maple-leaf-like grooves are composed of one radial linear groove and five spiral grooves (spiral groove I- spiral groove V), spiral groove I-spiral groove IV are symmetrically distributed on both sides of the radial linear groove, spiral groove I is the same as spiral groove IV, spiral groove II is the same as spiral groove III, and spiral groove V is close to the radial linear groove The inner diameter end of the sealing ring is connected, the high-pressure side is on the outer diameter of the sealing ring, and the radial linear groove opens on the edge of the outer diameter of the sealing ring. The line shape of the imitation maple leaf-shaped groove edge is a spiral line.

[0042] The circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com