Large-thrust high-speed hydraulic cylinder and work method thereof

A hydraulic cylinder and high-thrust technology, applied in the hydraulic field, can solve problems such as difficulty in providing high output speed, achieve the effects of shortening work preparation time, compact system structure, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

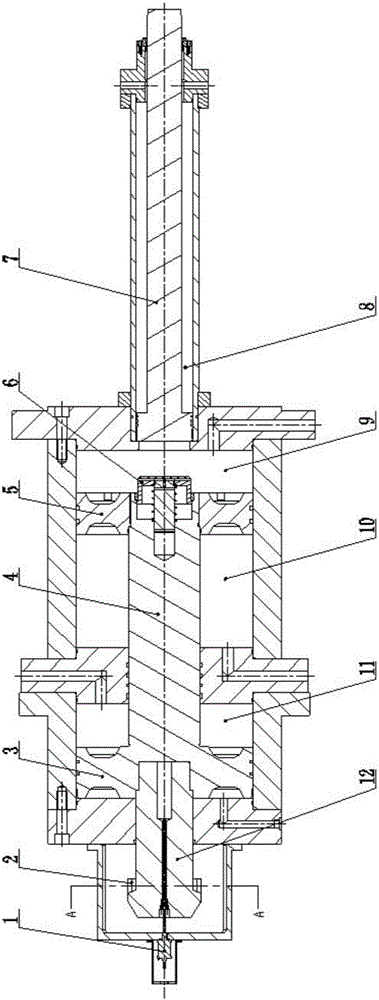

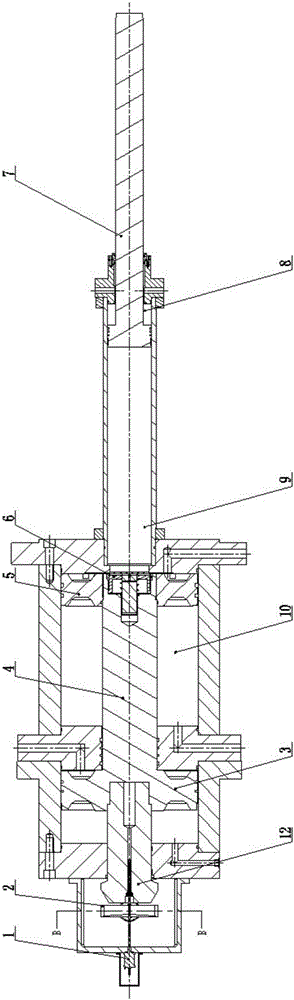

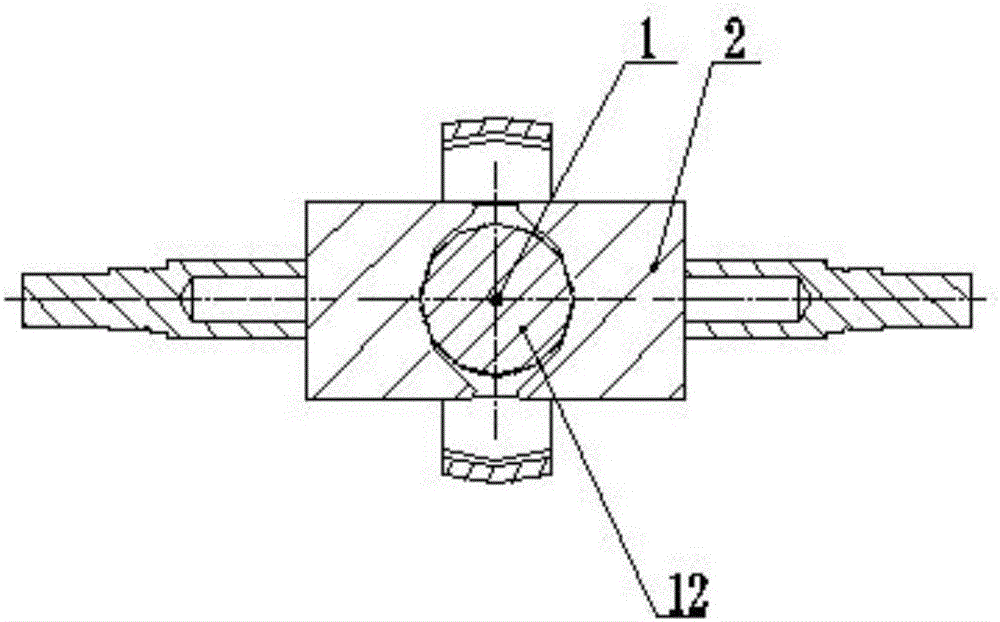

[0036] The present invention will be described in further detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

[0037] A high-thrust, high-speed hydraulic cylinder includes a high-speed hydraulic cylinder, a piston-type accumulator, and a pressure-increasing sensor. One axial end of the hydraulic cylinder is equipped with a high-speed cylinder piston rod, and the other axial end of the hydraulic cylinder is connected in series with a piston-type accumulator. Piston-type accumulator increases the speed of pushing out the piston rod;

[0038] In order to facilitate the description of this embodiment, attach figure 1 The directions shown are for explanation, the left side is the back and the right side is the front. The specific structure is:

[0039] The main body of the hydraulic cylinder is a horizontally arranged sealed ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com