Soft soil foundation reinforcing method and pipe ram for reinforcement

A soft soil foundation, pipe compaction technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as inability to apply to large-scale popularization and application, affecting the effect of dynamic compaction, and inability to solve deep reinforcement, etc. The effect of post-settling and settlement rate, the effect of obvious reinforcement, and the effect of short consolidation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

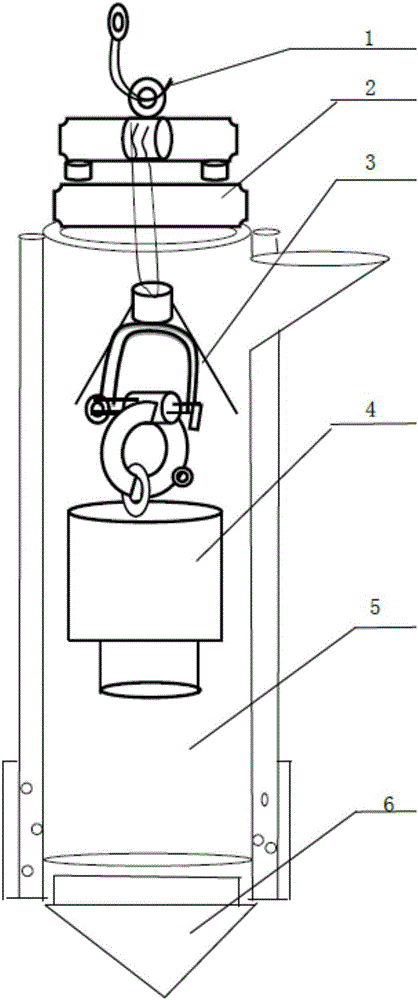

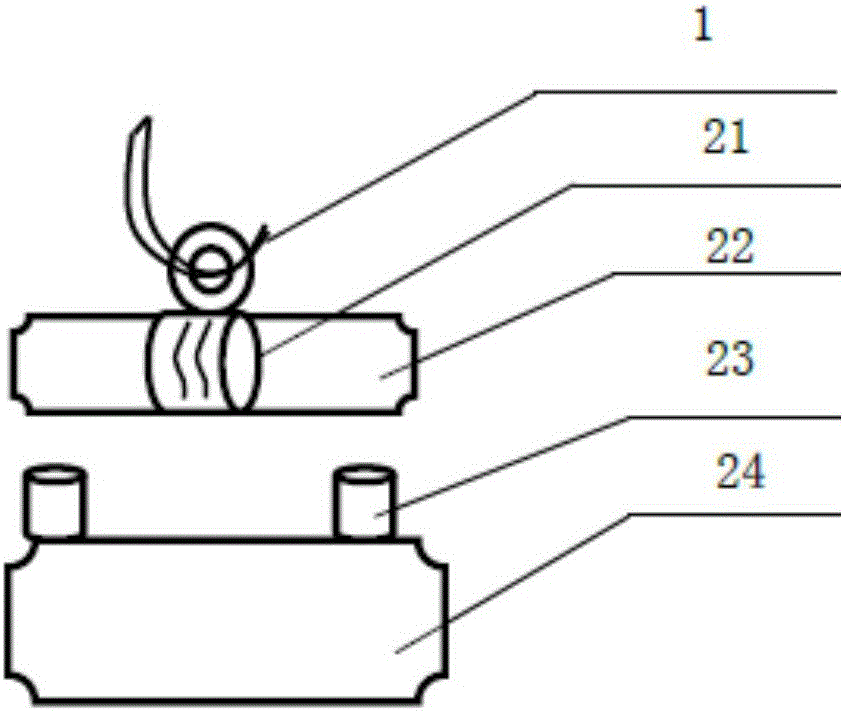

[0046] Such as Figure 1 to Figure 6 As shown, the pipe ram for strengthening soft soil foundation of the present invention is constructed by assembling a pipe tip 6 made of steel pipe, a ram tube 5, a vibrating hammer 2, a pincer-shaped decoupling device 3, and a pipe ram 4 made of steel pipe.

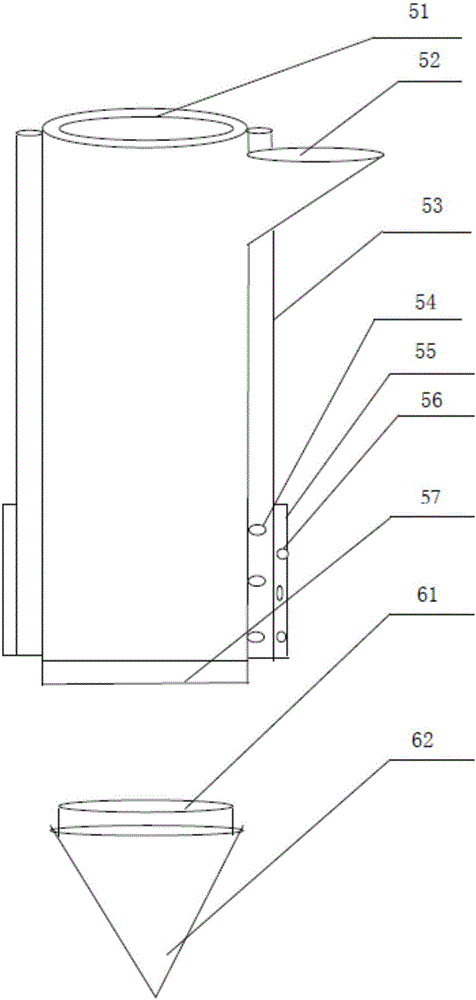

[0047] The ram tube 5 is made of steel pipes. Vacuum suction pipes 53 are arranged on both sides of the outer wall of the pipe body. A water filter 54 is arranged under the vacuum suction pipe 53, and is wrapped with 100 mesh nylon filters for 2 to 3 layers; to prevent water filtration during construction When the filter 54 is worn out, a water filter jacket 55 is set on the water filter 54, and a through hole 56 (apertu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com