A carbon fiber cable anchorage anchorage connection structure

A connection structure, carbon fiber technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problem of difficult to apply carbon fiber cable connection, etc., to achieve the effect of increasing the anchoring force and increasing the crimping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

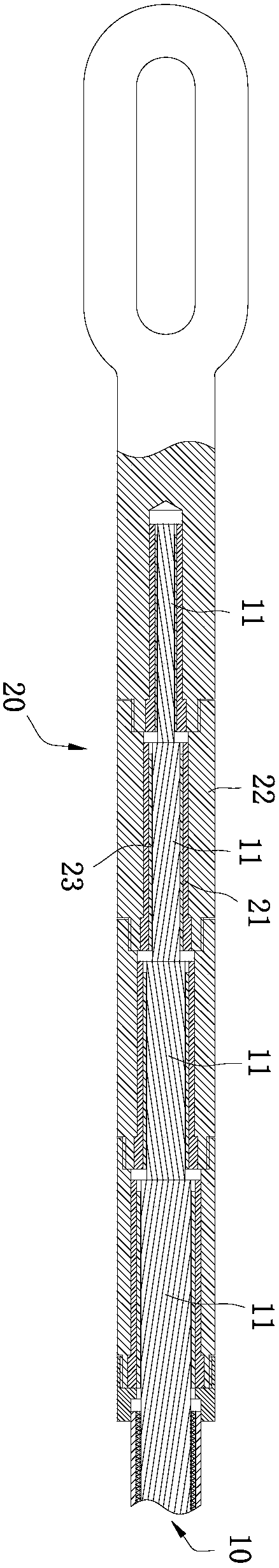

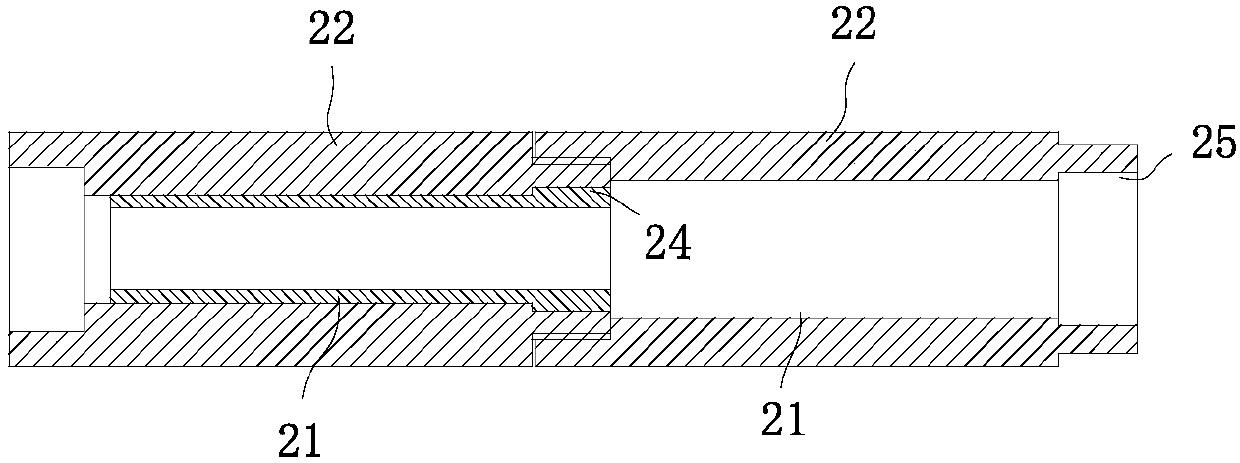

[0013] refer to figure 1 with figure 2 , an anchoring connection structure of a carbon fiber cable anchor in the present invention, including a carbon fiber cable 10, which has a stepped end, and the stepped end shrinks radially to the center to form a multi-stage crimping part 11; the anchor 20, its It includes a plurality of crimping pipe fittings that are crimped with the end of the step, and each crimping pipe fitting is crimped on each crimping portion 11 correspondingly in turn and connected end to end in sequence.

[0014] Wherein, each crimping tube includes a crimping tube 21 crimped outside the crimping part 11, a tension tube 22 sleeved outside the crimping tube 21, and a bushing 23 between the crimping tube 21 and the crimping part 11.

[0015] In this embodiment, the end of the carbon fiber cable 10 is a four-step stepped end, that is, it has four crimping parts 11. First, the crimping part 11 of the first stage is sequentially put on the bushing 23, the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com