Silane hydrophobically modified phosphorus-containing flame-retardant epoxy resin and preparation method thereof

An epoxy resin and hydrophobic modification technology, which is applied in the field of preparation of high-performance polymer materials, can solve problems such as accelerated aging of epoxy resin, flicker and partial discharge, and deterioration of mechanical properties, and achieve excellent compatibility, excellent resistance flammability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

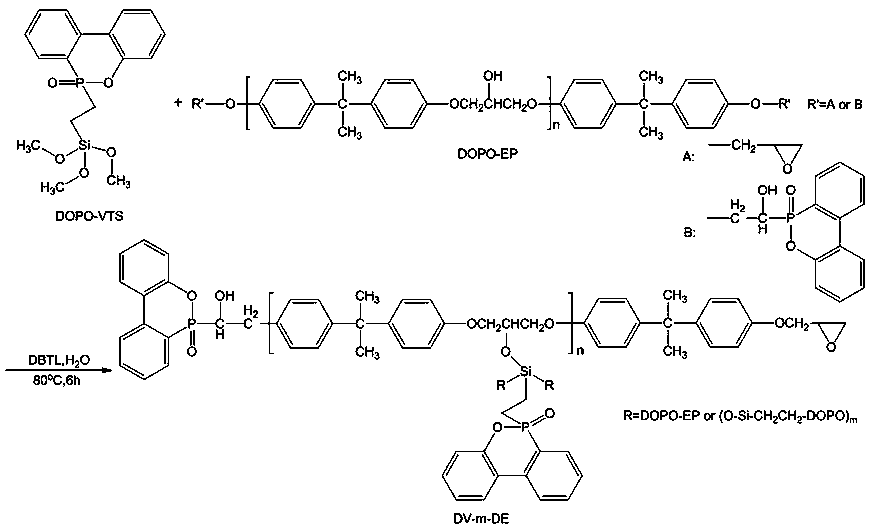

[0022] Add 40 g of DOPO-VTS, 100 g of DOPO-type epoxy resin, 0.8 g of dibutyltin dilaurate (DBTL) and 4 g of deionized water into a 250 mL round-bottomed flask equipped with a condenser, and stir at 80 °C for 6 h , and then evacuated for 2 h to obtain a yellow colloidal silane hydrophobically modified phosphorus-containing flame-retardant epoxy resin (DV-m-DE).

[0023] Add 100 g DV-m-DE, 50 g methyltetrahydrophthalic anhydride and 0.4 g N,N-dimethylbenzylamine into a polytetrafluoroethylene beaker, heat and stir at 40 °C to mix evenly, then pour Put it into a preheated mold, put it into a vacuum oven to remove air bubbles, and then heat up and solidify. The curing conditions are: 100°C for 3 hours, 130°C for 10 hours, and the cured product is cooled in the furnace, and then demoulded and sampled.

[0024] The vertical combustion grade of the epoxy resin reaches V-0 grade, and the surface contact angle is 106.3°.

Embodiment 2

[0026] Add 20 g of DOPO-VTS, 150 g of DOPO-type epoxy resin, 1.6 g of dibutyltin dilaurate (DBTL) and 0.5 g of deionized water into a 250 mL round bottom flask equipped with a condenser, and stir at 110 °C for 2 h, and then evacuated for 0.5 h to obtain a yellow colloidal silane hydrophobically modified phosphorus-containing flame-retardant epoxy resin (DV-m-DE).

[0027] Add 140 g DV-m-DE, 90 g hexahydrophthalic anhydride and 0.8 g N-benzylpyrazine sodium hexafluoroantimonate into a polytetrafluoroethylene beaker, heat and stir at 80 °C to mix evenly, then pour into the preheated Put it into a vacuum oven to remove air bubbles, then heat up and solidify; the curing conditions are: 140 °C for 1 h, 170 °C for 6 h, and the cured product is cooled in the furnace, and then demolded and sampled.

[0028] The vertical combustion grade of the epoxy resin reaches V-0 grade, and the surface contact angle is 92.7°.

Embodiment 3

[0030] Add 30 g of DOPO-VTS, 130 g of DOPO-type epoxy resin, 1.2 g of dibutyltin dilaurate (DBTL) and 2 g of deionized water into a 250 mL round bottom flask equipped with a condenser, and stir at 100 °C for 4 h , and then vacuum reaction for 1h to obtain yellow colloidal silane hydrophobically modified phosphorus-containing flame-retardant epoxy resin (DV-m-DE).

[0031] Add 120 g DV-m-DE, 70 g 3,4,5,6-tetrahydrophthalic anhydride and 0.6 g N-benzylquinoline sodium hexafluoroantimonate into a polytetrafluoroethylene beaker, 60 After heating and stirring at ℃ and mixing evenly, pour it into a preheated mold, put it in a vacuum oven to remove air bubbles, and then heat up and solidify. The curing conditions are: 120 ℃ for 2 hours, 150 ℃ for 8 hours. Sample demoulding.

[0032] The vertical combustion grade of the epoxy resin reaches V-0 grade, and the surface contact angle is 97.1°.

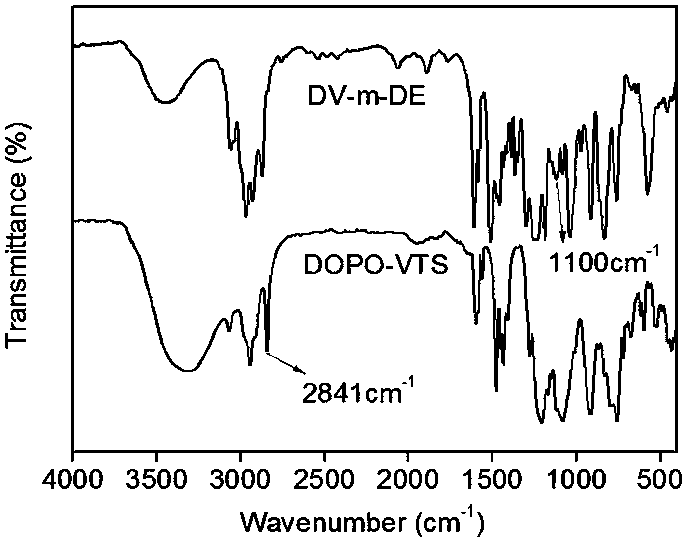

[0033] from image 3 It can be seen that in the infrared absorption spectrum of DOPO-VTS, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com