Mining gravel hoeing and conveying integrated machine

A technology of scraping and loading machines and integrated machines, which is applied in the direction of conveyors, mechanical conveyors, loading/unloading, etc., can solve the problems of long scrapping time, difficult operation, low work efficiency, etc., and achieve shorter scraping time and better operation Reduced difficulty and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

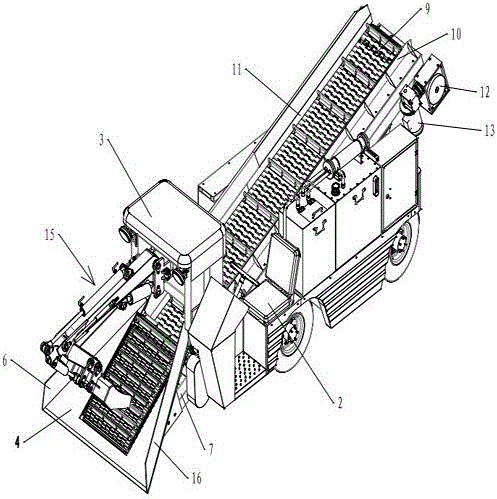

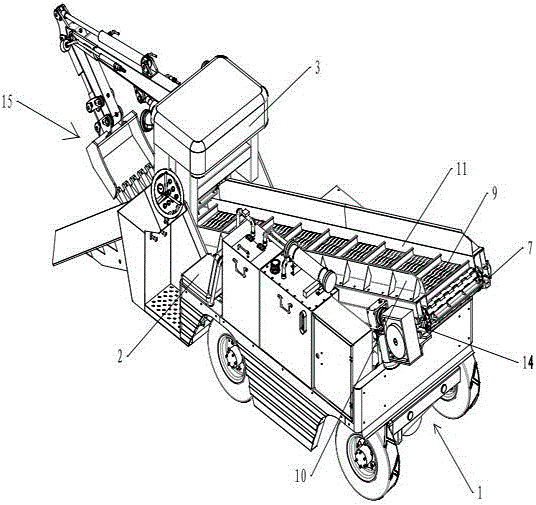

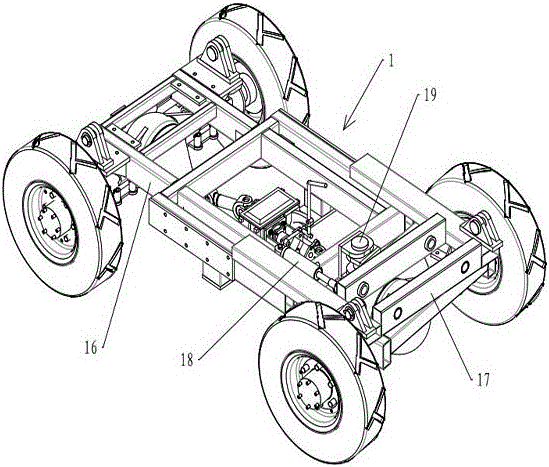

[0020] Depend on figure 1 , figure 2 and image 3 It can be seen that the all-in-one machine for mining crushed stones of the present invention includes front and rear wheels, a loader chassis 1, a wheel drive system and a driver's cab 2, and a gantry 3 is installed above the front part of the loader chassis 1, A slag removal device 15 is installed on the gantry 3, and a gravel conveying system is installed on the chassis 1 of the gantry 3 along the front and rear directions. After passing through the gantry frame 3, it extends to the bottom of the bucket system. The middle part of the bottom end of the frame 7 is hingedly connected with the top top of the front part of the loader chassis 1, and the rear part of the bottom end of the frame 7 is hingedly connected with the piston rod of the lifting cylinder 8. , the bottom of the cylinder body of the lifting cylinder 8 is hingedly connected to the top of the rear part of the loader chassis 1, and the middle rear part above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com