Automatic feeding device

The technology of a feeding device and a feeding car is applied in the field of automatic feeding device, which can solve the problems of affecting processing efficiency, poor accuracy of manipulator taking, and displacement of the feeding car, so as to achieve the effects of improving processing efficiency, good positioning, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

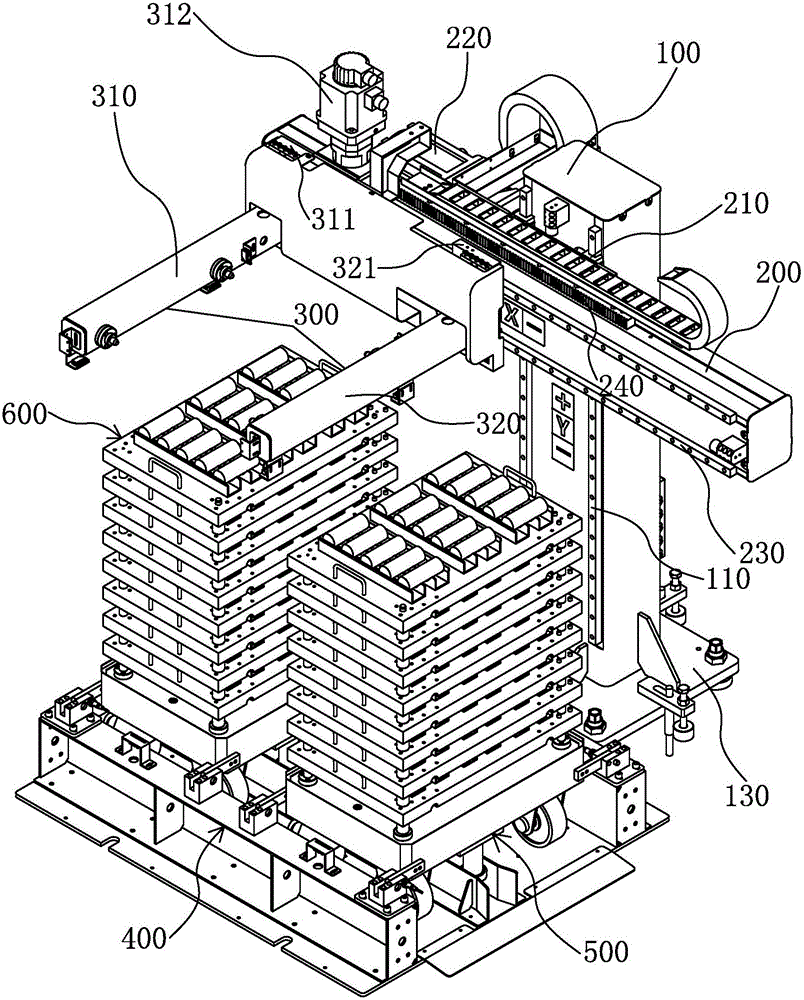

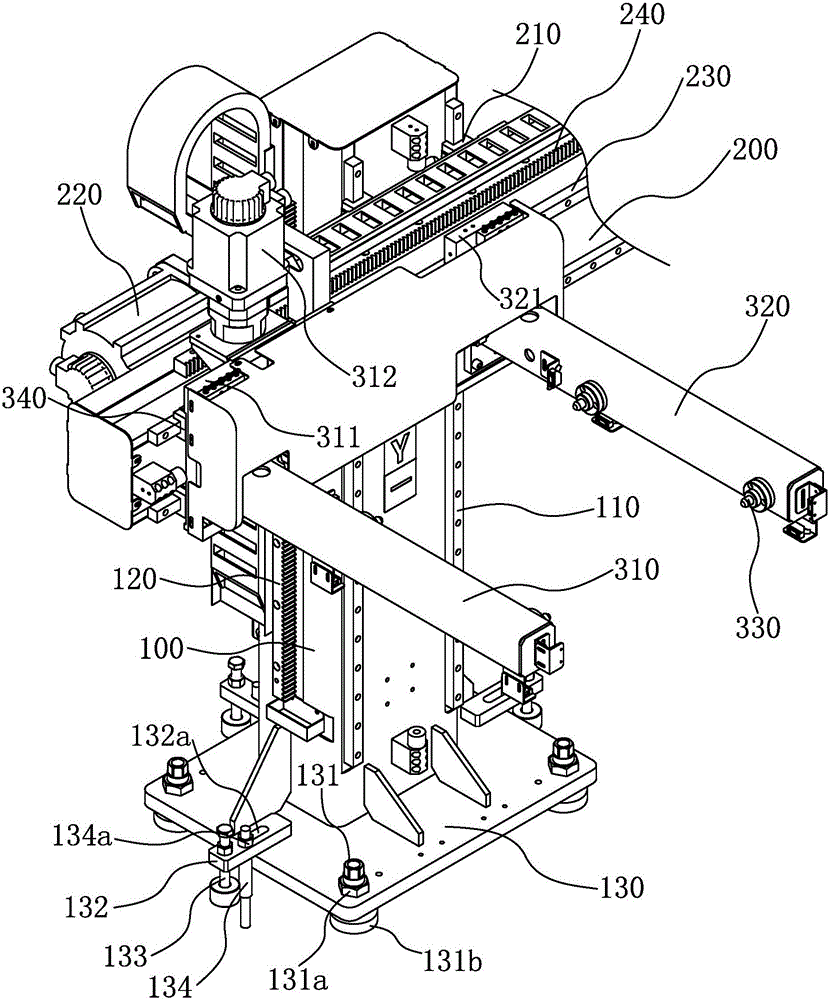

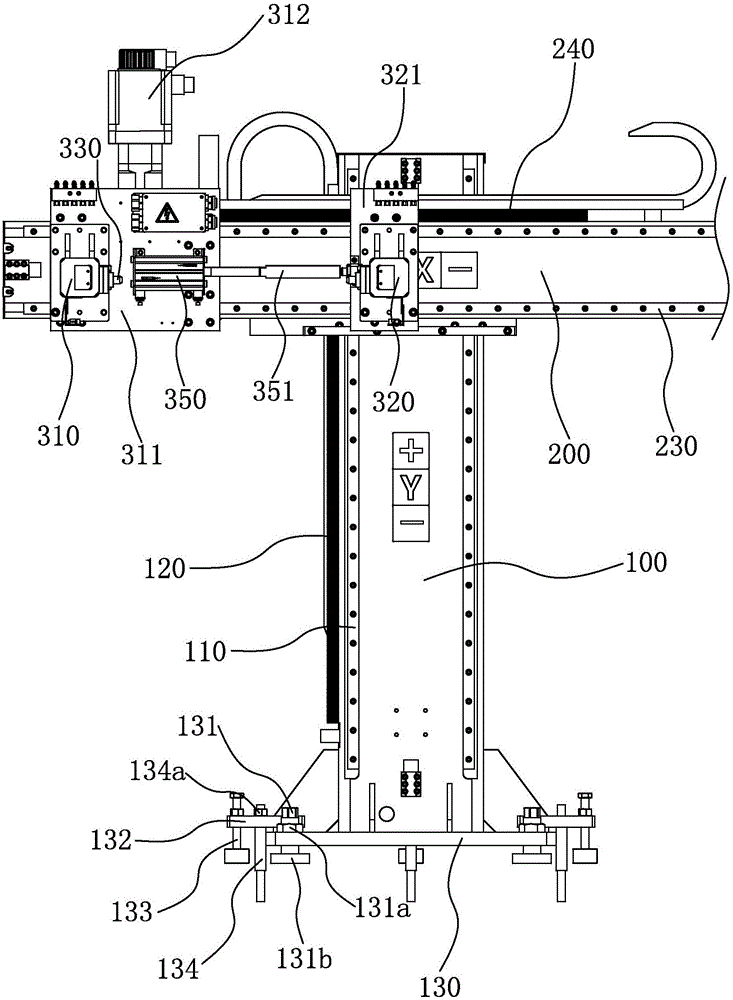

[0042] Such as figure 1 As shown, an automatic feeding device of the present invention includes a vertical arm 100 , a cross arm 200 , a manipulator assembly 300 , a fixed table 400 , a feeding cart 500 and a pallet body 600 .

[0043] Such as Figure 1 to Figure 3 As shown, the vertical arm 100 is erected and fixedly connected to a mounting surface. The mounting surface can be the ground or the surface of a certain fixed object. Two first guide rails 110 are erected on the vertical surface of the vertical arm 100. , a first rack 120 is mounted on an outer wall of the vertical arm 100 .

[0044] Such as Figure 1 to Figure 3 As shown, the cross arm 200 is arranged horizontally, and two first sliders 210 are erected on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com